In high-pressure environments, spring-energized PTFE seals perform exceptionally well. Their unique design leverages system pressure to create a more effective seal, ensuring reliability where many other seal types would fail. The internal spring provides an initial seating force, which is then amplified by the process pressure acting on the seal's profile.

The core principle is that a spring-energized PTFE seal uses the system pressure to its advantage. Instead of fighting the pressure, the seal's design harnesses it to increase the sealing force against the mating surfaces, making it more effective as pressure rises.

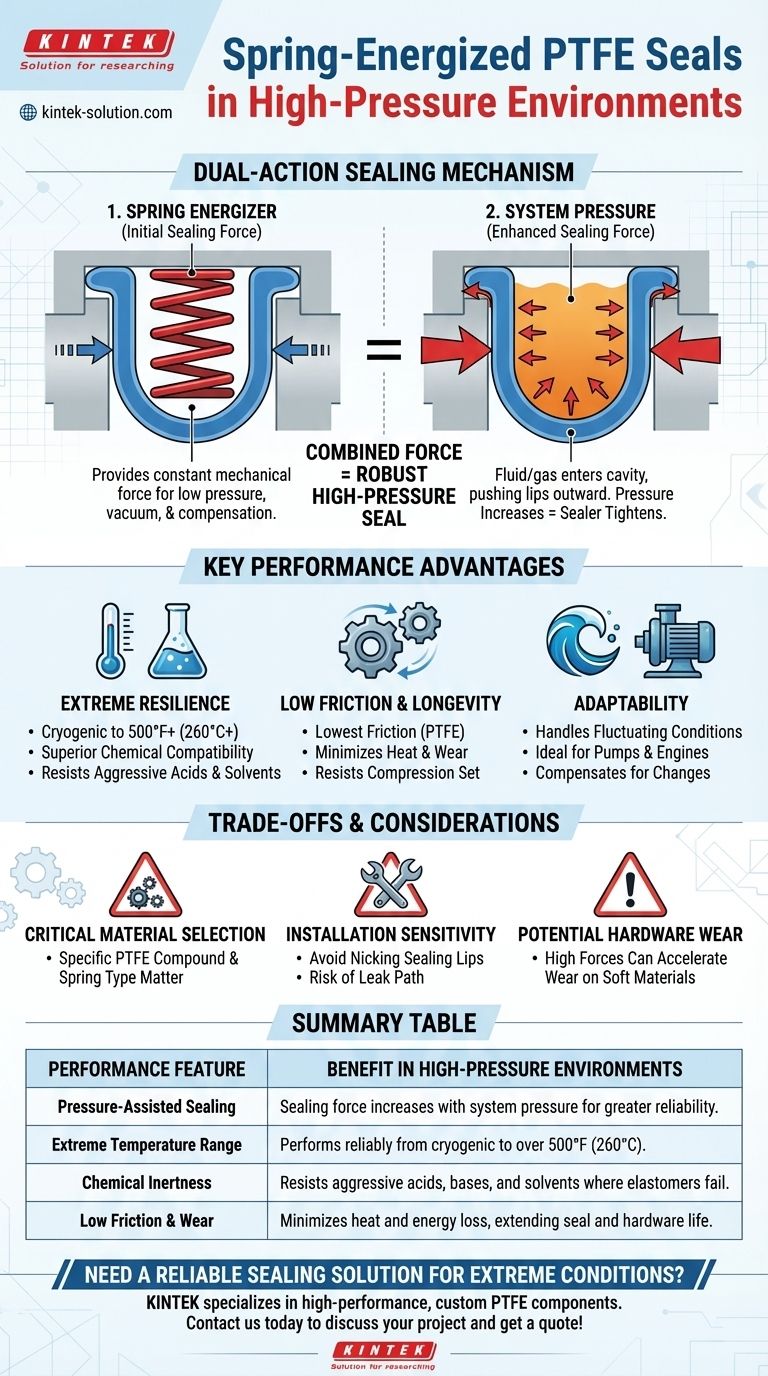

The Dual-Action Sealing Mechanism

To understand their high-pressure capability, you must look at the two distinct forces that create the seal: the mechanical force from the spring and the hydraulic force from the system pressure itself.

The Role of the Spring Energizer

The metal spring is the heart of the seal's versatility. It provides a constant, resilient mechanical force that presses the PTFE sealing lips against the hardware.

This initial force is critical for ensuring a reliable seal at low pressures or in a vacuum. It also compensates for minor dimensional changes caused by temperature fluctuations, hardware misalignment, or natural seal wear over time.

How System Pressure Enhances the Seal

The true advantage in high-pressure situations comes from the seal's U-cup or V-shaped profile. When the seal is exposed to system pressure, the fluid or gas enters the cavity of the "U" shape.

This pressure then acts uniformly on the inside of the seal, pushing the sealing lips outward with significant force. This force is directly proportional to the system pressure, meaning the higher the pressure, the tighter the seal.

Key Performance Advantages Beyond Pressure

While their pressure handling is a primary feature, these seals offer a combination of properties that make them suitable for the most demanding applications.

Extreme Temperature and Chemical Resilience

PTFE is a highly inert polymer. This gives the seals superior compatibility with a vast range of chemicals, including aggressive acids, bases, and solvents where traditional elastomers would quickly degrade.

They also maintain their properties across an exceptionally wide temperature range, performing reliably from cryogenic conditions up to temperatures exceeding 500°F (260°C).

Low Friction and Longevity

PTFE has one of the lowest coefficients of friction of any solid material. This minimizes frictional heat and wear, reducing energy loss and extending the operational life of both the seal and the mating hardware.

Furthermore, unlike many elastomers, PTFE seals are highly resistant to compression set, meaning they do not permanently deform under load and maintain their sealing force over long periods.

Adaptability in Dynamic Conditions

The combination of the flexible PTFE jacket and the resilient spring allows the seal to adapt to rapidly changing conditions. This makes them ideal for equipment like industrial pumps or engines where pressure and temperature can fluctuate significantly.

Understanding the Trade-offs and Considerations

No sealing solution is perfect for every scenario. To make an informed decision, you must be aware of the potential limitations.

Material Selection is Critical

The term "PTFE" refers to a family of materials. The performance of the seal is heavily dependent on the specific PTFE compound (e.g., filled with carbon, glass, or other polymers) and the type of spring energizer used (e.g., V-spring, canted coil). An incorrect specification can lead to premature failure.

Installation Sensitivity

The same features that make the seal effective can also make it sensitive to installation. Care must be taken to avoid scratching or nicking the PTFE sealing lips, as any damage can create a potential leak path, especially under high pressure.

Potential for Hardware Wear

While PTFE is low-friction, the high sealing forces generated under extreme pressure can accelerate wear on softer shaft or bore materials over millions of cycles. Proper hardware surface finish and hardness are critical considerations for ensuring system longevity.

Making the Right Choice for Your Application

Ultimately, the decision depends on the specific demands of your operating environment.

- If your primary focus is reliability in extreme pressure and dynamic conditions: A spring-energized seal is a primary candidate due to its pressure-assisted design and ability to compensate for changing conditions.

- If your primary focus is sealing aggressive chemicals or operating at temperature extremes: The material properties of PTFE make these seals one of the most robust choices available, far outperforming most elastomers.

- If your primary focus is minimizing friction in a high-pressure system: The low-friction nature of PTFE is a major advantage, but always pair it with correctly specified hardware to manage long-term wear.

By understanding how these seals use system pressure to create a more robust seal, you can confidently specify them for your most critical applications.

Summary Table:

| Performance Feature | Benefit in High-Pressure Environments |

|---|---|

| Pressure-Assisted Sealing | Sealing force increases with system pressure for greater reliability. |

| Extreme Temperature Range | Performs reliably from cryogenic to over 500°F (260°C). |

| Chemical Inertness | Resists aggressive acids, bases, and solvents where elastomers fail. |

| Low Friction & Wear | Minimizes heat and energy loss, extending seal and hardware life. |

Need a reliable sealing solution for extreme conditions?

KINTEK specializes in manufacturing high-performance, custom PTFE components like spring-energized seals for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals perform flawlessly under high pressure, extreme temperatures, and with aggressive chemicals.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Let us provide the robust sealing solution your critical application demands.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation