At its core, the sustainability of Polytetrafluoroethylene (PTFE) expansion joints stems from three key attributes: exceptional durability, superior chemical inertness, and high-efficiency sealing. Unlike components that require frequent replacement, PTFE’s longevity minimizes waste and resource consumption, while its ability to safely contain aggressive media prevents environmental contamination and improves operational safety.

The true environmental contribution of a PTFE expansion joint is not just in its material composition, but in its ability to enhance the long-term safety, efficiency, and cleanliness of the entire industrial system it protects.

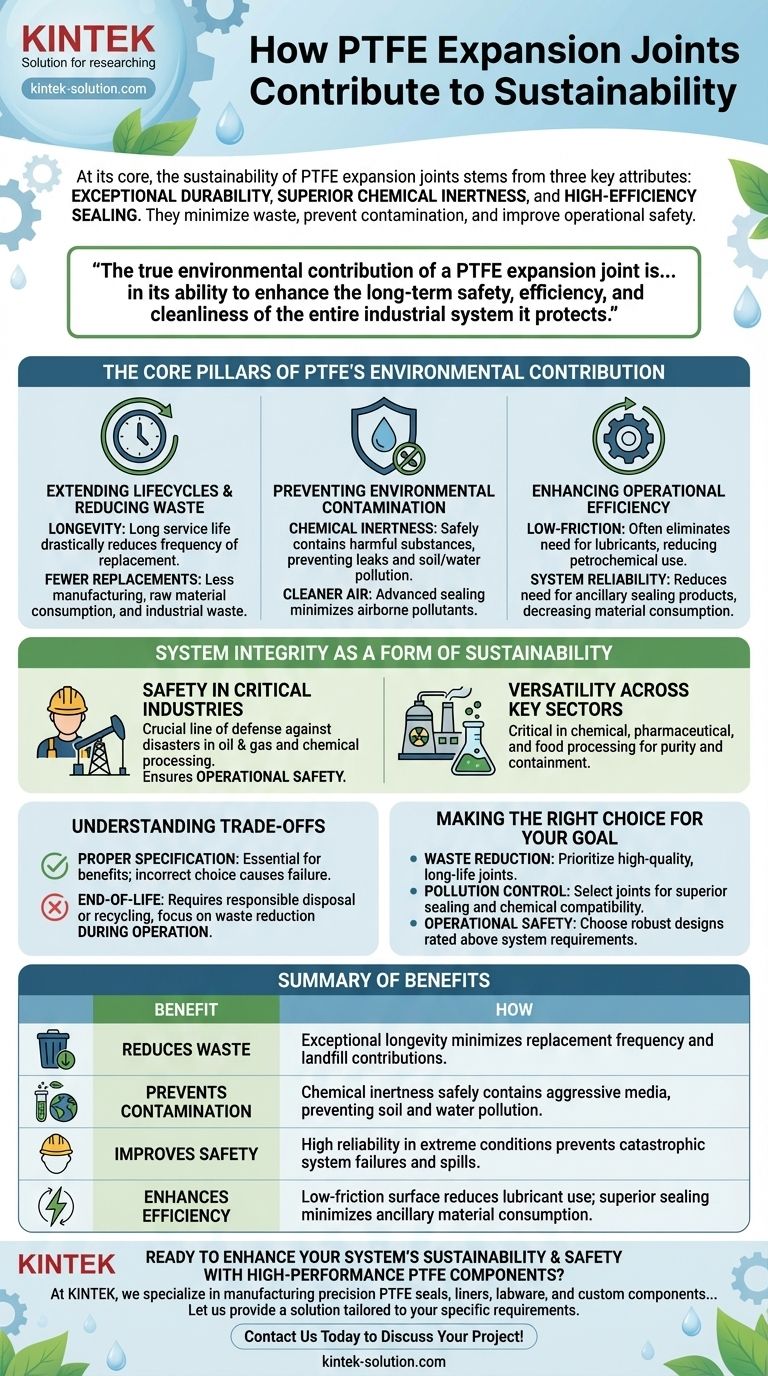

The Core Pillars of PTFE's Environmental Contribution

To understand the sustainability benefits, we must look beyond the component itself and see its impact on the larger operation. PTFE's unique properties translate directly into measurable environmental advantages.

Extending Lifecycles and Reducing Waste

The most direct contribution to sustainability is longevity. PTFE expansion joints have a very long service life, especially in corrosive or high-temperature environments where other materials would quickly degrade.

This durability drastically reduces the frequency of replacement. Fewer replacements mean less manufacturing, less raw material consumption, and significantly less industrial waste sent to landfills over the operational life of a plant.

Preventing Environmental Contamination

PTFE is renowned for its chemical inertness. It is non-reactive and non-corrosive when exposed to even the most aggressive chemicals.

This property ensures that harmful substances being transported through a piping system are safely contained, preventing leaks that could contaminate soil and waterways. Furthermore, their advanced sealing capabilities minimize the escape of airborne pollutants, contributing to cleaner air quality around industrial sites.

Enhancing Operational Efficiency

PTFE's low-friction surface often eliminates the need for lubricants. This directly reduces the consumption of petrochemical-based products and prevents their potential leakage into the environment.

Additionally, the reliability of PTFE components can reduce the need for ancillary sealing products like complex gaskets, further decreasing material consumption and potential points of failure within a system.

System Integrity as a Form of Sustainability

In high-stakes industries, preventing failure is the ultimate form of environmental protection. A single component failure can lead to catastrophic spills and releases that dwarf any other sustainability metric.

Safety in Critical Industries

In sectors like oil and gas or chemical processing, expansion joints must handle extreme pressures, temperatures, and highly corrosive materials.

The stability and reliability of PTFE in these conditions are paramount. By ensuring system integrity, these joints act as a crucial line of defense against environmental disasters, making operational safety a key component of sustainability.

Versatility Across Key Sectors

The benefits of PTFE are not confined to one industry. Its use is critical in a range of applications where purity and containment are non-negotiable.

These include chemical plants handling corrosive acids, pharmaceutical facilities maintaining sterile environments, and food processing plants ensuring product purity. In each case, PTFE helps meet stringent safety and environmental standards.

Understanding the Trade-offs

While highly beneficial, maximizing the sustainability of PTFE expansion joints requires proper context and application. The material is not a universal solution, and its benefits are only realized through correct implementation.

The Importance of Proper Specification

The environmental advantages of a PTFE joint are entirely dependent on it being correctly specified for the application's pressure, temperature, and chemical environment.

An incorrectly chosen or poorly installed joint can fail prematurely. This not only negates its long-life benefits but can also cause the very leaks and safety incidents it was meant to prevent.

End-of-Life Considerations

PTFE's durability means it does not readily biodegrade. While this is an advantage during its service life, it requires a responsible end-of-life disposal or recycling plan. The focus of its sustainability rests heavily on waste reduction during operation, which is typically where the largest environmental impact occurs.

Making the Right Choice for Your Goal

To leverage the sustainability of PTFE, align your selection criteria with your primary environmental objective.

- If your primary focus is waste reduction: Prioritize high-quality joints from reputable manufacturers to ensure the longest possible service life and minimize replacement cycles.

- If your primary focus is pollution control: Select a joint specifically engineered for superior sealing and verified compatibility with the most corrosive chemicals in your system.

- If your primary focus is operational safety: Choose robustly designed joints rated well above the maximum pressure and temperature of your system to prevent catastrophic failure.

Ultimately, choosing a PTFE expansion joint is an investment in long-term operational stability and environmental responsibility.

Summary Table:

| Sustainability Benefit | How PTFE Expansion Joints Achieve It |

|---|---|

| Reduces Waste | Exceptional longevity minimizes replacement frequency and landfill contributions. |

| Prevents Contamination | Chemical inertness safely contains aggressive media, preventing soil and water pollution. |

| Improves Safety | High reliability in extreme conditions prevents catastrophic system failures and spills. |

| Enhances Efficiency | Low-friction surface reduces lubricant use; superior sealing minimizes ancillary material consumption. |

Ready to enhance your system's sustainability and safety with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your expansion joints are built for maximum durability, chemical resistance, and operational integrity—helping you reduce waste, prevent contamination, and protect the environment.

Let us provide a solution tailored to your specific pressure, temperature, and chemical requirements. Contact us today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In what types of environments are PTFE lip seals commonly used? Ideal for Extreme Conditions

- What are the characteristics of unidirectional PTFE lip seals? Superior One-Way Sealing for Demanding Applications

- Why is the quality of PTFE resin important for structured and expanded PTFE? Ensure Long-Term Sealing Integrity

- What role do fillers play in structured PTFE? Enhancing Strength, Wear, and Thermal Performance

- What are O-rings and why are they commonly used? A Guide to Simple, Reliable Sealing

- What industries commonly use PTFE-lined pipes? Achieve Ultimate Corrosion Resistance & Purity

- What is the compressive strength of bronze-filled PTFE? A Guide to High-Strength PTFE for Mechanical Parts

- What is the purpose of comparing spring energized PTFE seals to elastomeric seals? A Guide to Choosing the Right Seal