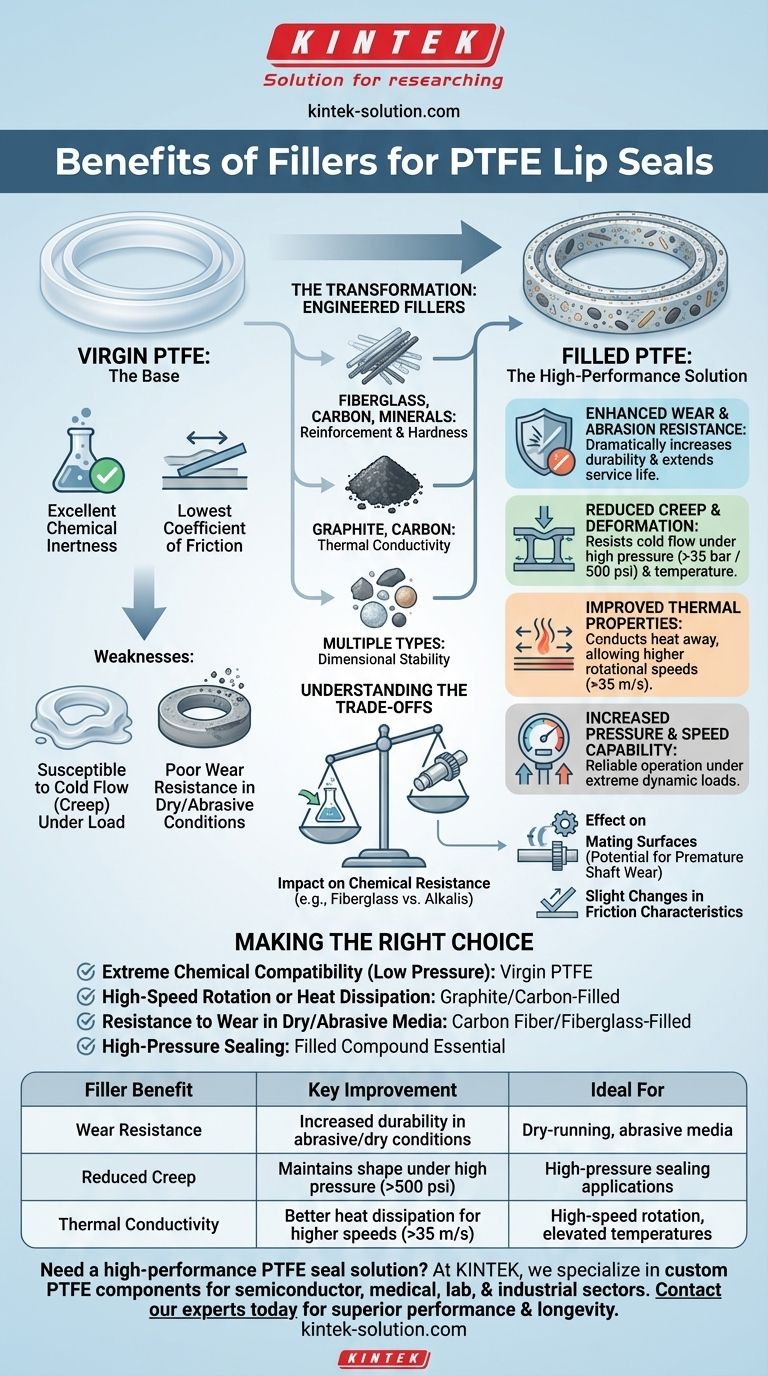

In short, fillers are added to Polytetrafluoroethylene (PTFE) to fundamentally enhance its mechanical properties. Fillers primarily increase wear resistance, reduce creep (the tendency to deform under load), and improve thermal conductivity, allowing the seal to perform in applications far beyond the capabilities of unfilled, or "virgin," PTFE.

While virgin PTFE offers exceptional chemical resistance and low friction, it is mechanically soft. Fillers act as a reinforcing matrix, transforming PTFE from a versatile material into a high-performance engineering component capable of withstanding extreme pressure, temperature, and wear.

Why Virgin PTFE Isn't Always Enough

To understand the role of fillers, we must first appreciate the inherent strengths and weaknesses of pure PTFE.

The Strengths of Pure PTFE

Virgin PTFE is an extraordinary material on its own. Its primary advantages include a nearly universal chemical inertness and one of the lowest coefficients of friction of any solid material. This makes it ideal for applications involving corrosive media or where low drag is critical.

The Inherent Weaknesses

The main limitation of virgin PTFE is its softness. It is susceptible to two key failure modes:

- Cold Flow (Creep): Under sustained pressure and temperature, PTFE will slowly deform or "flow" away from the load, leading to a loss of sealing force.

- Poor Wear Resistance: In dry-running conditions or when abrasive media is present, the soft material wears away quickly, drastically reducing the seal's service life.

The Core Benefits Fillers Provide

Fillers are precisely engineered additives that are blended with raw PTFE to create a composite material that directly counteracts these weaknesses.

Enhanced Wear and Abrasion Resistance

This is the most common reason to add a filler. Harder particles like fiberglass, carbon, or minerals are embedded within the PTFE matrix, dramatically increasing the material's durability and extending seal life in dry or abrasive environments.

Reduced Creep and Deformation

Fillers provide structural reinforcement, making the PTFE composite much more resistant to cold flow. This ensures the seal maintains its shape and contact pressure, which is critical for handling high pressures (in excess of 35 bar / 500 psi) and elevated temperatures.

Improved Thermal Properties

Pure PTFE is a poor conductor of heat, which can lead to overheating at the seal lip in high-speed applications. Fillers like graphite and carbon improve thermal conductivity, effectively pulling heat away from the sealing surface and allowing for higher rotational speeds (over 35 m/s).

Increased Pressure and Speed Capability

By improving dimensional stability and wear resistance, fillers allow PTFE seals to operate reliably at much higher pressures and surface speeds than their virgin counterparts. The reinforced material is less likely to extrude or wear out under extreme dynamic loads.

Understanding the Trade-offs

Adding fillers is not a universal upgrade; it is an engineering decision that involves specific trade-offs.

Impact on Chemical Resistance

While the PTFE base remains inert, some fillers can be attacked by chemicals that virgin PTFE would easily resist. For example, fiberglass can be attacked by strong alkalis or hydrofluoric acid, a situation where a different filler or virgin PTFE would be necessary.

Effect on Mating Surfaces

Hard fillers can be more abrasive to the mating hardware (the shaft) than soft, virgin PTFE. A fiberglass-filled seal running on a soft stainless steel shaft may cause premature shaft wear if the surface hardness is not specified correctly.

Changes in Friction Characteristics

Although filled PTFE still has very low friction, the addition of certain particles can slightly increase the coefficient of friction compared to virgin material. This is usually a minor consideration but can be relevant in highly sensitive, low-torque applications.

Making the Right Choice for Your Application

The choice of a filled PTFE seal over a virgin one depends entirely on the demands of your specific operating environment.

- If your primary focus is extreme chemical compatibility in low-pressure systems: Virgin PTFE is often the best and most cost-effective choice.

- If your primary focus is high-speed rotation or heat dissipation: A graphite or carbon-filled compound is the superior option for its thermal conductivity.

- If your primary focus is resistance to wear in dry or abrasive media: A carbon fiber or fiberglass-filled seal will provide a significantly longer service life.

- If your primary focus is high-pressure sealing: A filled compound is essential to prevent creep and maintain seal integrity over time.

Ultimately, selecting the correct filler transforms a standard PTFE seal into a precisely engineered solution for your most demanding challenges.

Summary Table:

| Filler Benefit | Key Improvement | Ideal For |

|---|---|---|

| Wear Resistance | Increased durability in abrasive/dry conditions | Dry-running, abrasive media |

| Reduced Creep | Maintains shape under high pressure (>500 psi) | High-pressure sealing applications |

| Thermal Conductivity | Better heat dissipation for higher speeds (>35 m/s) | High-speed rotation, elevated temperatures |

Need a high-performance PTFE seal solution for your demanding application?

At KINTEK, we specialize in manufacturing custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal engineered to handle your specific pressure, temperature, and wear challenges.

Contact our experts today to discuss your requirements and get a solution that delivers superior performance and longevity.

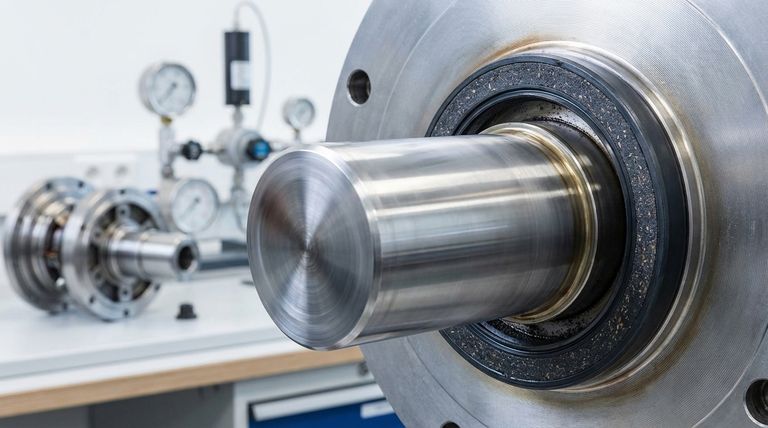

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech