In short, Polytetrafluoroethylene (PTFE) contributes to manufacturing sustainability primarily through exceptional durability and by reducing operational friction. This means components last significantly longer, which minimizes waste from replacements, and machinery operates more efficiently, which reduces energy consumption. Its chemical inertness and resistance to harsh conditions also make it a key enabler for renewable energy technologies like solar panels and wind turbines.

The core principle of PTFE's sustainability is not in the material itself, but in its function as an "enabler." By dramatically increasing the lifespan, efficiency, and reliability of larger systems, it reduces the overall consumption of energy, raw materials, and maintenance resources over the product's entire lifecycle.

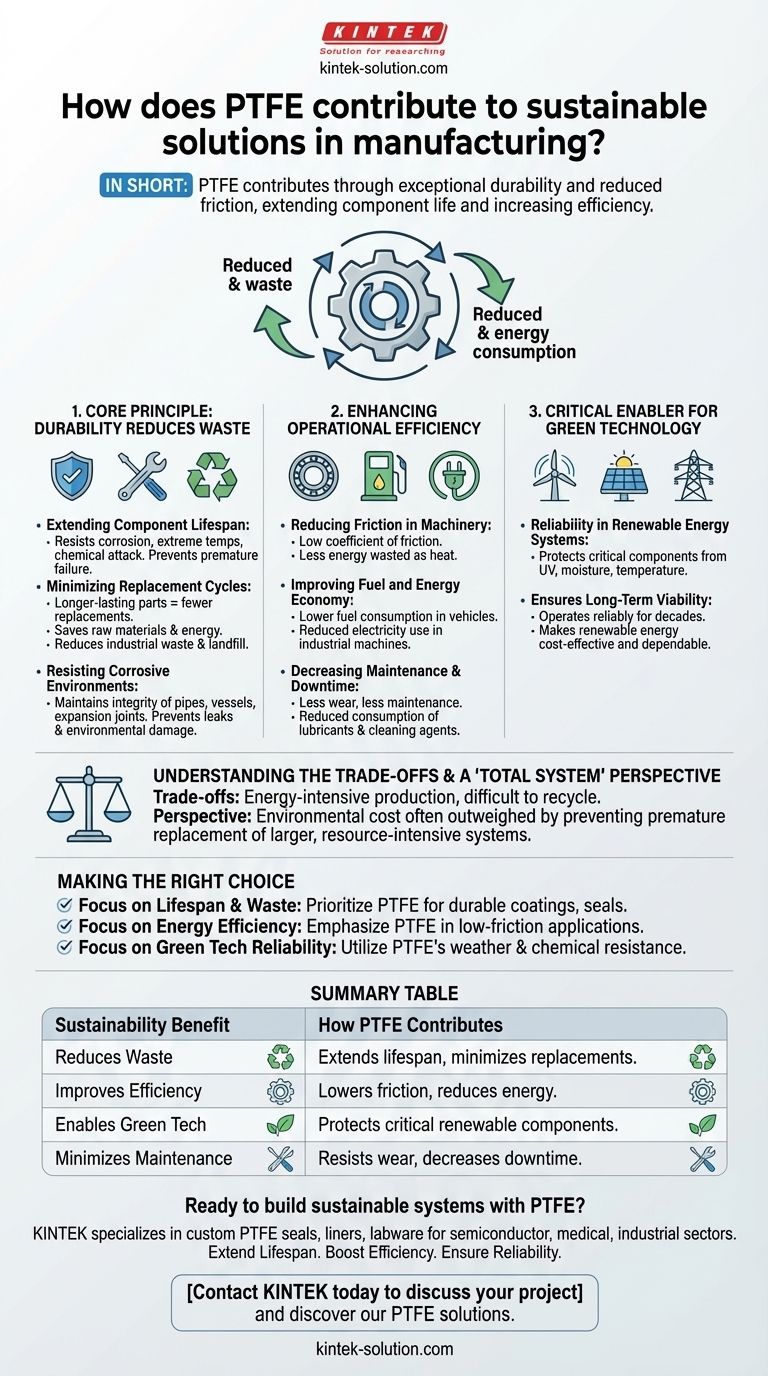

The Core Principle: Durability Reduces Waste

One of the most significant environmental impacts in manufacturing is the constant cycle of producing, replacing, and disposing of worn-out parts. PTFE directly addresses this by extending the operational life of components.

Extending Component Lifespan

PTFE is renowned for its resistance to corrosion, extreme temperatures, and chemical attack. When used as a coating or a component material for parts like bearings, screws, or seals, it acts as a protective shield.

This shielding dramatically increases the part's lifespan, preventing premature failure due to wear and tear.

Minimizing Replacement Cycles

Longer-lasting parts directly translate to less frequent replacements. This reduces the demand for manufacturing new parts, which in turn saves raw materials and the energy required for production and transportation.

Fewer replacements also mean less scrap and industrial waste being sent to landfills.

Resisting Corrosive Environments

In chemical processing, PTFE's ability to handle highly corrosive materials without degrading is critical. It ensures the integrity of pipes and vessels, preventing leaks that could cause environmental damage.

This durability also applies to components like expansion joints, which last longer than traditional alternatives and reduce fugitive emissions.

Enhancing Operational Efficiency

Sustainability is also about reducing the energy consumed during operation. PTFE's extremely low coefficient of friction plays a central role in improving the efficiency of mechanical systems.

Reducing Friction in Machinery

When applied to moving parts within an engine or industrial machine, PTFE minimizes the frictional forces that resist motion.

Less friction means less energy is wasted as heat, and more of the input energy is converted into useful work.

Improving Fuel and Energy Economy

This reduction in friction has a direct impact on performance. In vehicles, it can lead to lower fuel consumption and reduced emissions by improving engine and brake system efficiency.

In industrial settings, machines with PTFE-coated components require less electricity to perform the same tasks, lowering the facility's overall energy footprint.

Decreasing Maintenance and Downtime

Components that resist wear and friction require less maintenance. This reduces the consumption of lubricants and cleaning agents and minimizes manufacturing downtime.

Efficient, continuous operation is a key component of a sustainable manufacturing process.

A Critical Enabler for Green Technology

Beyond improving existing processes, PTFE is a crucial material in the construction of modern renewable energy infrastructure. Its unique properties are essential for ensuring the long-term viability of these technologies.

Reliability in Renewable Energy Systems

PTFE is used in solar panels and wind turbines to protect critical components from harsh environmental factors like UV radiation, moisture, and temperature fluctuations.

Its durability ensures these systems can operate reliably for decades, which is essential for making renewable energy a cost-effective and dependable power source.

Understanding the Trade-offs

An objective analysis requires acknowledging the complete picture. While PTFE's properties deliver significant sustainability benefits during a product's use phase, its own lifecycle presents challenges.

Manufacturing and End-of-Life

The production of fluoropolymers like PTFE is an energy-intensive process. Furthermore, the same chemical stability that makes PTFE so durable also makes it extremely persistent in the environment and difficult to recycle using conventional methods.

A "Total System" Perspective

The key is to evaluate PTFE's impact on the entire system. Its use is justified from a sustainability standpoint when its inclusion dramatically extends the life or boosts the efficiency of a much larger, more resource-intensive product.

The environmental cost of producing a small PTFE component is often vastly outweighed by the savings achieved by preventing the premature replacement of a large engine, a turbine blade, or an entire industrial system.

Making the Right Choice for Your Application

To leverage PTFE effectively, your decision should align with your primary sustainability goal.

- If your primary focus is maximizing equipment lifespan and reducing waste: Prioritize PTFE for durable coatings, seals, and expansion joints to minimize replacement cycles and material consumption.

- If your primary focus is improving energy efficiency: Emphasize using PTFE in low-friction applications within mechanical systems to reduce overall fuel or electricity consumption.

- If your primary focus is ensuring reliability in green technology: Utilize PTFE's weather and chemical resistance to protect critical components in renewable energy or emissions-control systems.

Ultimately, strategically applying PTFE allows you to build more durable, efficient, and reliable systems that form the foundation of a sustainable industrial future.

Summary Table:

| Sustainability Benefit | How PTFE Contributes |

|---|---|

| Reduces Waste | Extends component lifespan, minimizing replacements and material use. |

| Improves Efficiency | Lowers friction in machinery, reducing energy consumption. |

| Enables Green Tech | Protects critical components in solar panels, wind turbines, and more. |

| Minimizes Maintenance | Resists corrosion and wear, decreasing downtime and resource use. |

Ready to build more sustainable and efficient manufacturing systems with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, labware, and other components for the semiconductor, medical, laboratory, and industrial sectors. By leveraging PTFE's unique properties, we help you:

- Extend Equipment Lifespan: Reduce waste and replacement costs with incredibly durable components.

- Boost Operational Efficiency: Lower energy consumption with low-friction parts.

- Ensure Reliability: Protect critical systems in harsh environments.

From prototypes to high-volume orders, we deliver the quality and custom fabrication you need to meet your sustainability goals.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech