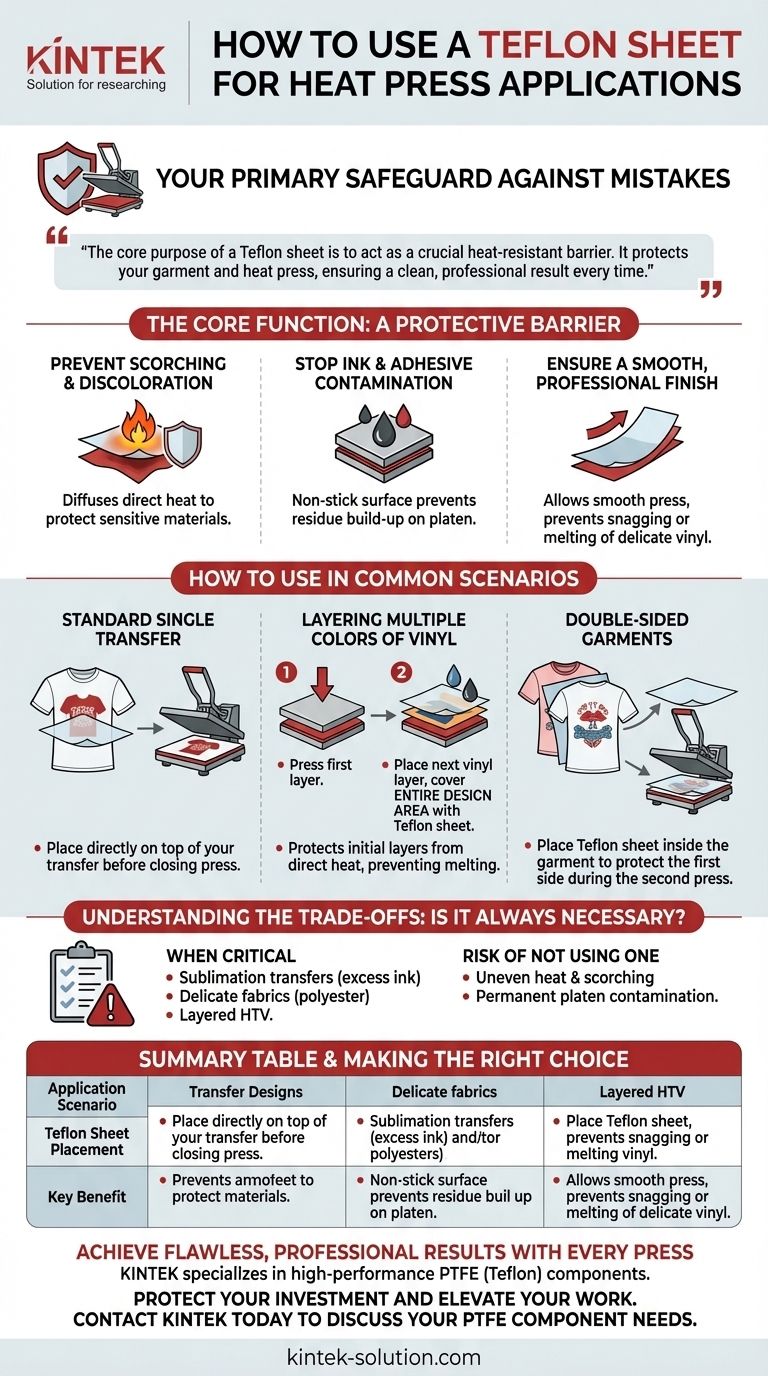

In heat press applications, a Teflon sheet is your primary safeguard against costly mistakes. You use it by placing it directly on top of your transfer design before closing the press. This simple action creates a protective, non-stick barrier between the hot upper platen and your project, preventing scorching, ink smudging, and adhesive residue.

The core purpose of a Teflon sheet is not just to cover your design, but to act as a crucial heat-resistant barrier. It protects both your garment from damage and your heat press from contamination, ensuring a clean, professional result every time.

The Core Function: A Protective Barrier

A Teflon sheet is a reusable, non-stick material specifically designed to withstand high temperatures. Its role is to solve the most common problems encountered during heat transfer applications.

Preventing Scorching and Discoloration

The intense heat from the press platen can easily burn or discolor sensitive fabrics. The Teflon sheet acts as a shield, diffusing the direct heat to protect the material underneath your design.

Stopping Ink and Adhesive Contamination

Without a barrier, excess ink from sublimation transfers or adhesive from heat transfer vinyl (HTV) can stick to the upper platen. This residue can then ruin subsequent projects. The non-stick surface of the Teflon sheet prevents this entirely, keeping your equipment clean.

Ensuring a Smooth, Professional Finish

The sheet ensures that the heat press glides smoothly over the transfer material without snagging or melting delicate vinyl. This helps produce an even press and a flawless final appearance.

How to Use a Teflon Sheet in Common Scenarios

While the basic principle is simple, the exact placement depends on your specific project.

For a Standard Single Transfer

This is the most common use. Place your garment on the press, position your transfer paper or vinyl design, and then lay the Teflon sheet directly on top before closing the heat press.

When Layering Multiple Colors of Vinyl

If you are creating a multi-color design with HTV, you must press each layer separately. After pressing the first layer, place the next vinyl layer on top and cover the entire design area (including the already-pressed vinyl) with the Teflon sheet. This protects the initial layers from direct heat, preventing them from shrinking or melting.

For Double-Sided Garments

When pressing a design on both the front and back of a shirt, you risk reheating the first side's design when you press the second. To prevent this, place a Teflon sheet inside the garment, separating the front and back layers. You should still use another sheet on top of the design you are actively pressing.

Understanding the Trade-offs: Is It Always Necessary?

While you can technically operate a heat press without a Teflon sheet, it is not recommended. The small convenience of skipping this step is heavily outweighed by the potential risks.

When a Teflon Sheet is Critical

Its use is almost non-negotiable when working with sublimation transfers, as excess ink can easily sublimate onto your platen. It is also essential for protecting delicate fabrics like polyester or for any project involving layered heat transfer vinyl.

The Risk of Not Using One

Skipping the sheet exposes your project to direct, potentially uneven heat, increasing the risk of scorching. More importantly, it exposes your expensive heat press platen to permanent contamination from melted vinyl and stray inks, which can compromise all future work.

Making the Right Choice for Your Goal

Using a protective sheet is a matter of best practice. Your specific goal will determine exactly how you use it.

- If your primary focus is protecting your heat press: Always use a Teflon sheet as a top cover to prevent any ink or adhesive from ever touching the platen.

- If your primary focus is protecting the garment: Use the sheet on top to prevent burns and place it inside the garment for any double-sided printing.

- If your primary focus is achieving clean, layered designs: Use the sheet to shield previously pressed vinyl layers from direct heat during subsequent presses.

Ultimately, integrating a Teflon sheet into your workflow is a small, simple step that ensures the quality and longevity of both your projects and your equipment.

Summary Table:

| Application Scenario | Teflon Sheet Placement | Key Benefit |

|---|---|---|

| Standard Single Transfer | Directly on top of the transfer design | Prevents scorching and platen contamination |

| Layering Multiple HTV Colors | Covering the entire design area (including pressed layers) | Protects initial vinyl from shrinking/melting |

| Double-Sided Garments | On top of the design AND inside the garment | Shields the first side's design when pressing the second |

Achieve Flawless, Professional Results with Every Press

Using a high-quality Teflon sheet is a simple step that guarantees the longevity of your equipment and the quality of your finished products. For heat press applications demanding precision and reliability, the right material matters.

KINTEK specializes in manufacturing high-performance PTFE (Teflon) components, including heat press sheets, for the industrial and specialized apparel markets. Our sheets are engineered for superior non-stick properties, exceptional heat resistance, and durability to withstand repeated use.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Protect your investment and elevate your work. Contact KINTEPT today to discuss your PTFE component needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE-jacketed spring energized seals? Unlock Unmatched Sealing Performance

- What are the different types of PTFE gaskets available? Choose the Right Seal for Your Application

- In which industries are PTFE flange gaskets commonly used? Essential Sealing Solutions for Demanding Applications

- How does a PTFE Lined Ball Valve function? Achieve Reliable Flow Control in Corrosive Environments

- What are the operating conditions where PTFE slide bearings perform best? Optimize for High Load & Low Speed

- What are the common uses of PTFE Lined Globe Valves? Essential for Corrosive & High-Purity Flow Control

- How does Teflon benefit the fabric and carpet industry? Achieve Superior Stain Resistance

- How did PTFE lined butterfly valves address corrosion resistance challenges? Provide a Robust Barrier Against Corrosive Media