Teflon's primary benefit to the fabric and carpet industry is its ability to impart superior stain resistance. By creating a microscopic shield around each fiber, its famous nonstick property prevents liquid spills and dry soil from bonding to the material, allowing them to be blotted up or brushed away easily before they can cause a permanent stain.

The core challenge for any textile is maintaining its appearance against daily life. Teflon fabric protectors address this by fundamentally changing how spills interact with a surface—instead of soaking in, liquids bead up and roll off, buying you critical time to clean up messes.

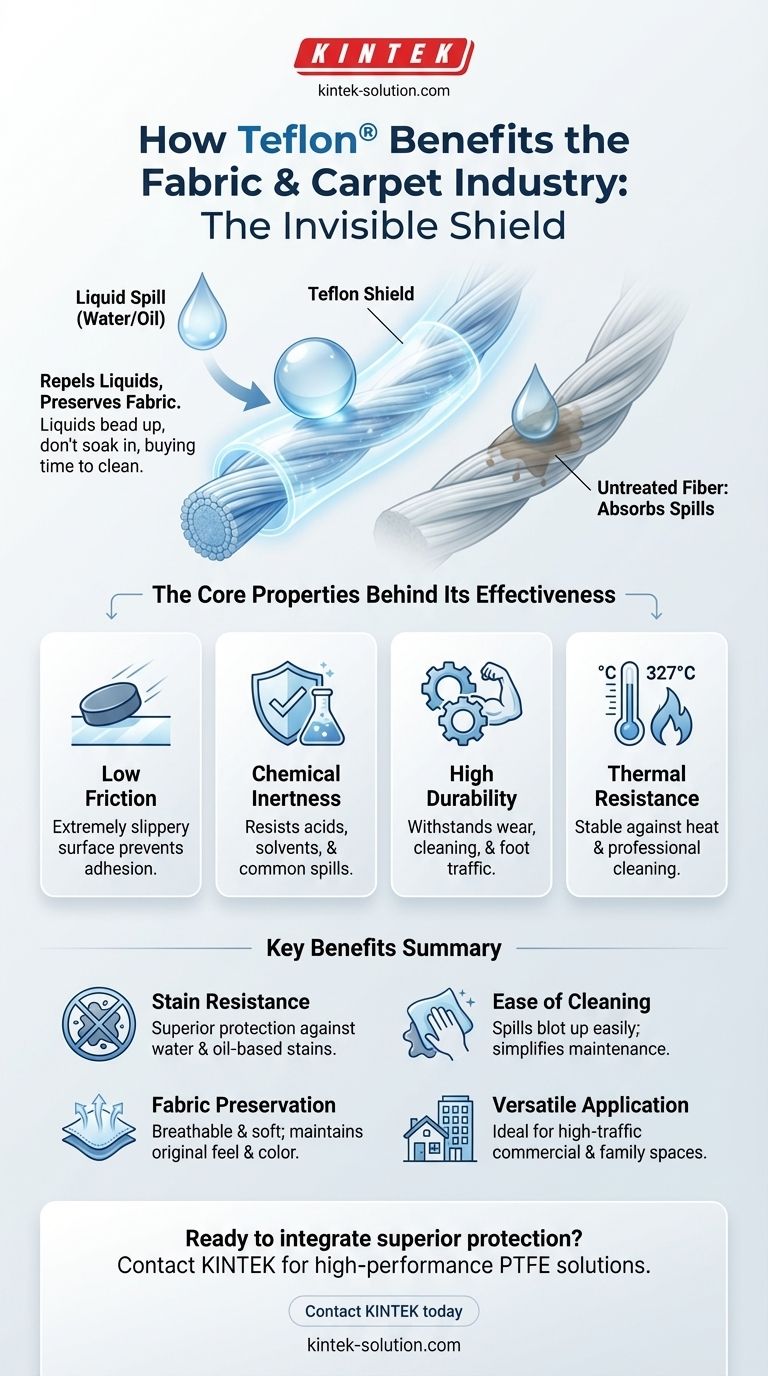

How Teflon Creates a Protective Shield

To understand the benefit, it's essential to look at the mechanism. A Teflon treatment isn't a solid layer that suffocates the fabric; it's an invisible, molecular-level coating that bonds to individual fibers.

The Principle of Low Friction

At its core, Teflon is one of the most slippery substances known. Its extremely low coefficient of friction is the key to its nonstick capability.

When a liquid like wine or coffee hits an untreated fiber, it easily "grips" the surface and wicks into the material. With a Teflon coating, the spill cannot adhere to the slick surface of the fiber and is forced to bead up.

Repelling Both Water and Oil

A key advantage of this technology is its effectiveness against a wide range of substances. The chemical structure of the coating is designed to repel both water-based spills (like juice or soda) and oil-based spills (like salad dressing or motor oil).

This dual protection makes it a highly versatile solution for real-world environments where the nature of the next spill is unpredictable.

Preserving Fabric Feel and Breathability

Because the protector coats individual fibers rather than sealing the entire surface, the fabric or carpet remains breathable.

This means the treatment does not change the texture, feel, or color of the material. The original softness of a carpet or the comfortable feel of upholstery is fully preserved.

The Core Properties Behind Its Effectiveness

Teflon’s performance isn’t based on a single feature but on a combination of inherent material properties that make it uniquely suited for fabric protection.

Exceptional Chemical Inertness

Teflon is highly resistant to a vast range of chemicals, including strong acids and solvents.

For a carpet or sofa, this translates into robust protection against common household spills, which can be acidic (coffee, wine) or alkaline. The coating doesn't react with the substance, preventing a chemical bond that would lead to a stain.

High Durability

The bond between the Teflon protector and the fabric fibers is strong, designed to withstand the wear and tear of normal use.

This means the protection lasts through foot traffic, vacuuming, and routine cleaning, ensuring its stain-resistant qualities are not a temporary benefit but a long-term feature.

Thermal Resistance

Teflon is stable across a wide range of temperatures (up to 327°C / 620°F).

While you won't subject your carpet to such extremes, this underlying thermal stability contributes to its overall durability. It ensures the protective coating won't degrade during manufacturing processes or professional cleaning methods like steam cleaning.

Understanding the Practical Limitations

Objectivity requires acknowledging that no solution is perfect. Understanding the trade-offs is key to having realistic expectations for a Teflon-treated fabric.

It Provides Resistance, Not Invincibility

A Teflon protector is a shield, not an impenetrable force field. It is designed to give you time to clean a spill.

A large volume of liquid, a hot spill, or a substance that is allowed to sit for an extended period may eventually penetrate the barrier. The key is to act quickly.

Effectiveness Can Diminish Over Time

While durable, the treatment can be worn down over many years, especially in extremely high-traffic areas.

Harsh, abrasive cleaning chemicals can also degrade the coating's effectiveness over time. Sticking to recommended cleaning procedures is essential for longevity.

Application Quality Matters

The performance of a Teflon protector is heavily dependent on the quality and evenness of its application during the manufacturing process.

A properly applied, factory-cured treatment will almost always outperform a post-purchase, do-it-yourself spray-on application in both effectiveness and durability.

Making the Right Choice for Your Goal

Integrating this understanding into your decision-making ensures you select a product that aligns with your maintenance and longevity requirements.

- If your primary focus is high-traffic commercial or family spaces: Prioritize carpets and fabrics with a factory-applied Teflon treatment for maximum durability and day-one performance.

- If your primary focus is preserving delicate or light-colored upholstery: The protection against both oil and water-based stains makes it an ideal choice for preventing discoloration from a wide variety of spills.

- If your primary focus is ease of maintenance: A Teflon treatment significantly reduces the effort required for cleaning, as most soil remains on the surface instead of becoming embedded in the fibers.

Ultimately, a Teflon treatment transforms fabric care from a reactive battle against stains into proactive, simplified maintenance.

Summary Table:

| Benefit | How Teflon Helps |

|---|---|

| Stain Resistance | Repels both water and oil-based spills, causing them to bead up on the surface. |

| Ease of Cleaning | Spills can be easily blotted or brushed away before they become permanent stains. |

| Fabric Preservation | Coats individual fibers without changing the feel, breathability, or color of the material. |

| Durability | Strong bond withstands foot traffic, vacuuming, and professional cleaning methods. |

| Versatility | Effective for high-traffic commercial spaces, family homes, and delicate upholstery. |

Ready to integrate superior protection into your products?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE (the base polymer of Teflon®) components. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact components you need for durable, reliable fabric and carpet treatments.

We serve the specialized needs of industrial manufacturers looking for quality and consistency. Let's discuss how our PTFE solutions can enhance your product line.

Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems