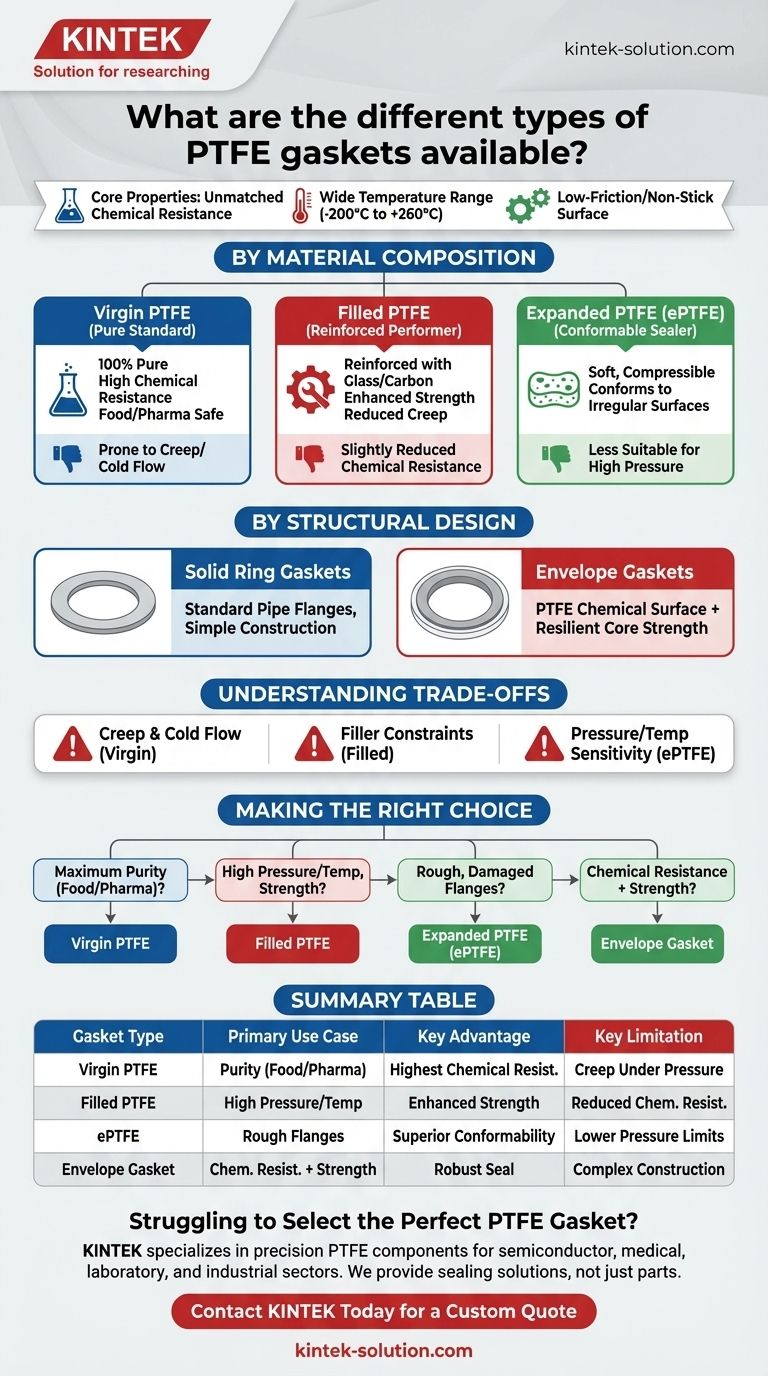

At its core, PTFE gasket selection is based on three main material types and several structural designs. The primary material variations are Virgin PTFE for general-purpose use, Filled PTFE, which is enhanced with agents like glass or carbon for improved mechanical properties, and Expanded PTFE (ePTFE), which offers superior compressibility for sealing irregular surfaces. These materials can be formed into different structures, such as simple ring gaskets or composite envelope gaskets.

Choosing the right PTFE gasket requires looking beyond its well-known chemical resistance. The critical decision lies in matching the specific mechanical, thermal, and surface demands of your flange to the correct material type—pure Virgin for purity, reinforced Filled for strength, or conformable Expanded for imperfect seals.

Understanding the Core Properties of PTFE

Before comparing gasket types, it's essential to understand the baseline properties that make Polytetrafluoroethylene (PTFE) a premier sealing material. All PTFE variants share these fundamental characteristics to some degree.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with the vast majority of industrial chemicals. This makes it a default choice for systems handling corrosive or high-purity media.

Wide Temperature Range

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum, from cryogenic conditions up to approximately 260°C (500°F). This stability makes them suitable for both extreme cold and high-heat processes.

Low-Friction, Non-Stick Surface

The material has an extremely low coefficient of friction and is non-adhesive. This reduces torque needed during assembly and simplifies disassembly and cleaning, as media are less likely to stick to the gasket surface.

Types of PTFE Gaskets by Material Composition

The most significant differences between PTFE gaskets come from their material composition. Each type is engineered to solve a specific set of problems that the others cannot.

Virgin PTFE Gaskets (The Pure Standard)

This is 100% pure, unmodified PTFE. It offers the highest chemical resistance and electrical insulation properties of all the types.

Because it contains no fillers, it is the preferred material for applications where contamination is a concern, such as in the food, beverage, and pharmaceutical industries.

Filled PTFE Gaskets (The Reinforced Performer)

Filled PTFE gaskets are composites where agents are added to the virgin PTFE base to enhance specific mechanical properties. The filler material directly targets the inherent softness of pure PTFE.

Common fillers include glass fibers to reduce creep and cold flow, carbon to improve wear resistance and compressive strength, and graphite to lower the coefficient of friction and improve thermal conductivity.

Expanded PTFE (ePTFE) Gaskets (The Conformable Sealer)

Expanded PTFE is a soft, highly compressible, and flexible material created through a specific manufacturing process. It is micro-porous and has a fibrous structure.

Its primary advantage is its ability to conform to rough, pitted, or damaged flange surfaces, creating a tight seal with low bolt load. This makes it ideal for older equipment or delicate flanges (like glass-lined steel) that cannot withstand high compression forces.

Types of PTFE Gaskets by Structural Design

Beyond material, the physical construction of the gasket also plays a critical role.

Solid Ring Gaskets

This is the most common and basic form—a flat ring or full-face gasket cut from a sheet of PTFE material (Virgin, Filled, or Expanded). It is used for standard pipe flanges.

Envelope Gaskets

An envelope gasket combines the best of two materials. It consists of a soft, compressible insert material (like a non-asbestos fiber) wrapped in a thin "envelope" of PTFE.

This design provides the superior chemical resistance of a PTFE sealing surface while relying on the insert's mechanical strength and resilience to maintain the seal under pressure.

Understanding the Trade-offs

While PTFE is an exceptional material, it is not without limitations. Choosing the right type means understanding these trade-offs.

The Challenge of Creep and Cold Flow

The most significant weakness of Virgin PTFE is its tendency to "creep" or "cold flow." This is the process where the material slowly deforms and moves away from the point of pressure over time, which can lead to a loss of bolt torque and potential leaks. This is the primary reason Filled PTFE was developed.

Filler Material Constraints

While fillers enhance mechanical properties, they can slightly compromise other characteristics. For example, adding glass fibers can reduce the gasket's overall chemical resistance compared to pure Virgin PTFE, as the filler itself may not be as inert.

Temperature and Pressure Sensitivity

The softness that makes ePTFE an excellent sealer for irregular surfaces also makes it less suitable for extremely high-pressure applications where a more rigid material is required. Each gasket type has an optimal pressure and temperature range that must be respected.

Making the Right Choice for Your Application

Your final selection should be guided by the single most critical demand of your sealing application.

- If your primary focus is maximum chemical purity or food/pharma use: Your choice is Virgin PTFE, as it introduces no potential contaminants.

- If your primary focus is high pressure, high temperature, or preventing gasket deformation: You require Filled PTFE with a filler (like glass or carbon) designed for compressive strength.

- If your primary focus is sealing damaged, rough, or delicate flanges: The superior conformability of Expanded PTFE (ePTFE) is the correct solution.

- If your primary focus is combining broad chemical resistance with robust mechanical strength: An Envelope Gasket offers a balanced and often cost-effective solution.

Ultimately, selecting the correct PTFE gasket comes down to identifying the one property—be it purity, strength, or conformability—that your system cannot compromise on.

Summary Table:

| Gasket Type | Primary Use Case | Key Advantage | Key Limitation |

|---|---|---|---|

| Virgin PTFE | Maximum chemical purity (food, pharma) | Highest chemical resistance, no contamination | Prone to creep/cold flow under pressure |

| Filled PTFE | High pressure/temperature, reduced creep | Enhanced mechanical strength (glass, carbon fillers) | Slightly reduced chemical resistance vs. Virgin PTFE |

| Expanded PTFE (ePTFE) | Sealing rough, damaged, or delicate flanges | Superior compressibility and conformability | Less suitable for very high-pressure applications |

| Envelope Gasket | Chemical resistance + mechanical strength | PTFE seal with resilient core for robustness | More complex construction than solid rings |

Struggling to Select the Perfect PTFE Gasket for Your Critical Application?

Choosing the wrong gasket can lead to costly downtime, leaks, and safety risks. KINTEK specializes in manufacturing precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We don't just supply parts; we provide sealing solutions. Our expertise ensures you get the right material (Virgin, Filled, or ePTFE) and design for your specific pressure, temperature, and chemical requirements.

Let us help you achieve a leak-free, reliable seal.

Contact KINTEB Today for a Custom Quote – From prototypes to high-volume orders, we deliver the precision and performance your operation demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the versatility of Teflon plastic sheets benefit different industries? Solve complex engineering challenges

- What are PTFE valve seat rings used for? Achieve a Leak-Proof Seal in Demanding Applications

- What factors affect the lifespan of PTFE tubing and rods? Ensure Long-Term Reliability for Your Critical Applications

- What are the advantages of graphite packing over PTFE packing? Superior Performance in High-Temp & High-Speed Applications

- What is the role of PFA in PTFE sheet welding? Key Insights for Seamless Chemical Resistance

- What are some industrial applications of PTFE coatings? Enhance Performance in Demanding Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- How does CNC machining benefit PTFE part production? Achieve Precision, Consistency & Complex Designs