At its core, a PTFE Lined Ball Valve is a quarter-turn valve that uses a rotating, hollow ball to control fluid flow. When the valve's handle is turned 90 degrees, the hole in the ball aligns with the pipe to allow flow; another 90-degree turn presents the solid side of the ball to block it. The critical feature is the Polytetrafluoroethylene (PTFE) lining on all internal surfaces, which protects the valve from corrosive media.

This valve's function is not just to start and stop flow, but to do so reliably within highly corrosive or high-purity environments. The PTFE lining acts as an inert barrier, making it the definitive choice where standard metal valves would corrode and fail.

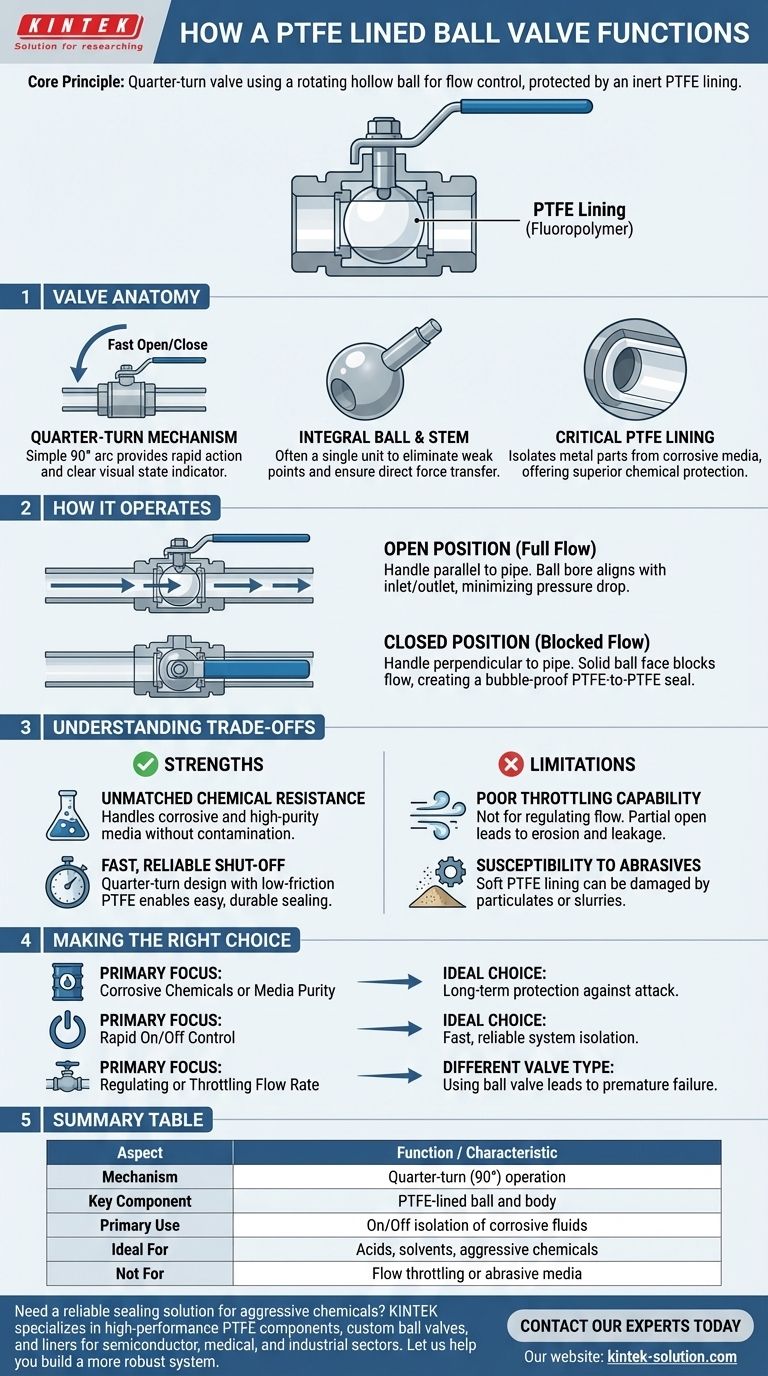

The Anatomy of the Valve

To understand its function, you must first understand its key components and how they work together to achieve a robust seal against aggressive chemicals.

The Quarter-Turn Mechanism

The valve is operated by a handle that moves through a 90-degree arc, or a "quarter turn."

This simple rotational motion makes the valve extremely fast to open or close, a critical feature in emergency shut-off applications. It provides a clear visual indicator of the valve's state: handle parallel to the pipe means open, perpendicular means closed.

The Integral Ball and Stem

The "ball" is a sphere with a hole, known as a port or bore, drilled through its center.

This ball is connected to the handle via a component called the stem. In high-quality designs, the ball and stem are often a single, integral unit to eliminate potential weak points and ensure a direct transfer of rotational force.

The Critical PTFE Lining

The defining characteristic is the uniform lining of PTFE (or similar fluoropolymers like PFA/FEP) applied to all "wetted" parts—the interior of the valve body, the entire surface of the ball, and the stem.

This lining isolates the structural metal of the valve from the fluid passing through it. PTFE is exceptionally non-reactive, providing superior protection against acids, solvents, and other harsh chemicals that would quickly degrade metal.

How It Operates: A Step-by-Step Breakdown

The valve’s operation is a simple mechanical process that provides a highly effective seal.

The Open Position

When the handle is turned parallel to the direction of flow, the stem rotates the ball so its bore is aligned with the pipe inlet and outlet.

In a "full port" design, the bore of the ball is the same diameter as the pipe, creating an unobstructed path. This minimizes pressure drop and allows for maximum flow.

The Closed Position

When the handle is turned perpendicular to the pipe, the stem rotates the ball 90 degrees. This positions the solid, un-bored part of the ball directly in the flow path, completely blocking it.

In this position, the PTFE-lined ball presses firmly against the PTFE valve seat, creating a tight, bubble-proof seal. The natural lubricity of PTFE helps ensure this seal can be achieved with low operational force, or "low torque."

Understanding the Trade-offs

No single valve is perfect for every situation. Understanding the inherent strengths and weaknesses of a PTFE Lined Ball Valve is critical for proper application.

Strength: Unmatched Chemical Resistance

This is the valve's primary advantage. The inert PTFE lining allows it to handle a vast range of corrosive and high-purity media without contamination or degradation of the valve itself.

Strength: Fast, Reliable Shut-off

The quarter-turn design provides rapid, unambiguous on/off action. Combined with the low-friction properties of PTFE, it offers a durable and easy-to-operate sealing solution.

Limitation: Poor Throttling Capability

These valves are not designed to regulate or "throttle" flow. When the ball is left in a partially open position, it creates high-velocity, turbulent flow that can rapidly erode the PTFE lining on the ball and seat.

This erosion will eventually cause the valve to leak when in the closed position, leading to failure. For flow regulation, a globe or diaphragm valve is a more appropriate choice.

Limitation: Susceptibility to Abrasives

While excellent for clean, corrosive liquids, the relatively soft PTFE lining can be damaged by abrasive media or slurries. Particulate matter can become embedded in the lining or scratch the sealing surfaces, compromising the valve's integrity.

Making the Right Choice for Your Application

Selecting the correct valve is about matching its capabilities to your operational goal.

- If your primary focus is handling corrosive chemicals or maintaining media purity: The fully lined design of this valve makes it the ideal choice, providing long-term protection against chemical attack.

- If your primary focus is rapid on/off control: The simple, low-torque quarter-turn mechanism ensures fast and reliable system isolation.

- If your primary focus is regulating or throttling flow rate: You must select a different valve type, as using a ball valve for this purpose will lead to premature failure.

By understanding its function as a specialized on/off device for aggressive media, you can leverage its strengths to build a more robust and reliable system.

Summary Table:

| Aspect | Function / Characteristic |

|---|---|

| Mechanism | Quarter-turn (90°) operation for fast open/close. |

| Key Component | PTFE-lined ball and body for chemical inertness. |

| Primary Use | On/Off isolation of corrosive or high-purity fluids. |

| Ideal For | Acids, solvents, and aggressive chemicals. |

| Not For | Flow throttling or abrasive media/slurries. |

Need a reliable sealing solution for aggressive chemicals?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom ball valves, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your equipment is protected from corrosive media.

Let us help you build a more robust and reliable system. Contact our experts today to discuss your specific requirements for prototypes or high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of low friction in PTFE lined valves? Achieve Smoother Operation and Lower Costs

- What are recommended tolerances for machining PTFE parts? Achieve Dimensional Stability & Cost-Effectiveness

- What are the benefits of white TFE Encapsulated silicone core gaskets? Optimize Purity & Performance

- What factors should be considered when selecting a PTFE butterfly valve? Ensure Peak Performance & Reliability

- What industries benefit from using pure PTFE in valve components and why? Ensure Absolute Purity in Critical Processes

- How do rubber gaskets compare to PTFE gaskets? Choose the Right Seal for Your Application

- What are the different machining processes suitable for Teflon/PTFE? Master Precision for Soft Materials

- How do PTFE rods contribute to energy efficiency in industrial applications? Reduce Friction & Power Consumption