PTFE flange gaskets are predominantly used in industries where chemical inertness, purity, and temperature resistance are critical operational requirements. You will find them specified for sealing applications in chemical processing, pharmaceuticals, food and beverage production, and semiconductor manufacturing, among other demanding fields.

The widespread adoption of PTFE gaskets is not accidental. It is a direct result of Polytetrafluoroethylene's unique molecular structure, which renders it almost universally resistant to chemical attack and incapable of contaminating the media it seals.

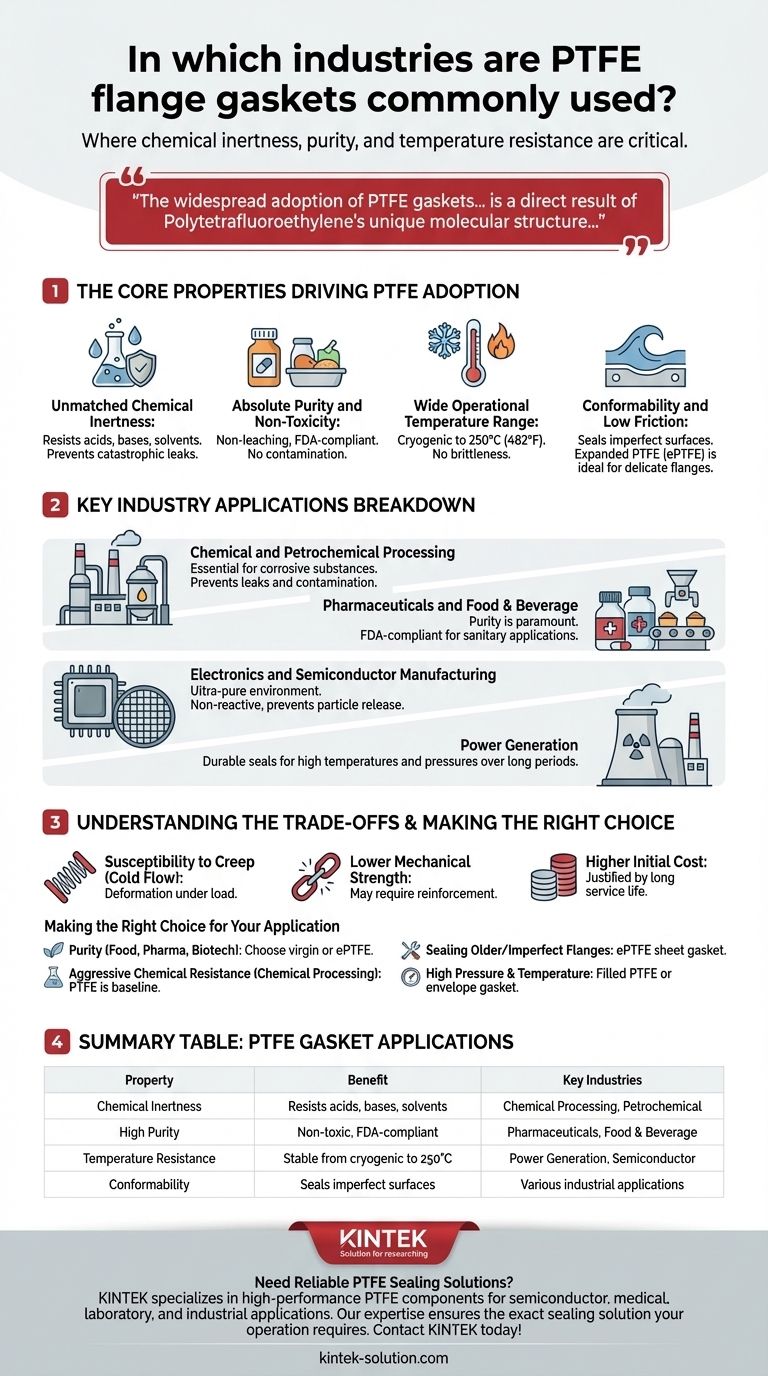

The Core Properties Driving PTFE Adoption

To understand why specific industries rely on PTFE, we must first examine its fundamental material properties. The choice of a gasket material is a technical decision driven by performance, not preference.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to a vast range of chemicals, including strong acids, aggressive bases, and corrosive solvents.

This property makes it the default choice in applications where other elastomers or polymers would rapidly degrade, ensuring the integrity of the seal and preventing catastrophic leaks.

Absolute Purity and Non-Toxicity

Standard PTFE is an inherently pure and non-toxic polymer. It does not leach chemicals or impart any taste or odor into the process media.

This characteristic is non-negotiable in hygienic industries. It's why virgin PTFE is often FDA-compliant and suitable for direct contact with food products and pharmaceutical compounds.

Wide Operational Temperature Range

PTFE gaskets perform reliably across a broad spectrum of temperatures, from cryogenic conditions up to approximately 250°C (482°F).

This thermal stability allows it to be used in systems that experience significant temperature fluctuations without becoming brittle or degrading, a common failure point for many other sealing materials.

Conformability and Low Friction

PTFE is a relatively soft material with a very low coefficient of friction. This allows it to conform well to flange surface irregularities, creating a tight seal even on less-than-perfect surfaces.

Variations like expanded PTFE (ePTFE) are even softer and more conformable, making them ideal for sealing delicate or damaged flanges, such as glass-lined or plastic piping.

Key Industry Applications Breakdown

The properties of PTFE directly map to the stringent requirements of several key industries.

Chemical and Petrochemical Processing

In this sector, gaskets are constantly exposed to highly corrosive substances. PTFE's ability to withstand nearly all industrial chemicals makes it essential for sealing pipelines, reactors, and vessels, preventing dangerous leaks and environmental contamination.

Pharmaceuticals and Food & Beverage

Purity is paramount. PTFE gaskets ensure that the final product—be it a medicine or a food item—is not contaminated by the sealing material. Its FDA-compliant grades are a requirement for sanitary applications.

Electronics and Semiconductor Manufacturing

The manufacturing of microchips involves ultra-pure chemicals and requires an environment free of contaminants. PTFE's high purity and non-reactive nature prevent it from releasing particles that could ruin sensitive electronic components.

Power Generation

Power plants, including nuclear facilities, require durable seals that can withstand high temperatures and pressures over long periods. The stability and reliability of PTFE make it a trusted material for critical sealing points in these environments.

Understanding the Trade-offs

No material is perfect. While PTFE is exceptionally capable, an objective advisor must also highlight its limitations.

Susceptibility to Creep (Cold Flow)

The most significant limitation of PTFE is creep, or cold flow. Under sustained bolt load and temperature, the material can slowly deform and "flow" out of the flange, leading to a loss of sealing stress and potential leakage.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, PTFE is a soft material. In extremely high-pressure applications, it may require reinforcement, such as in an envelope gasket or by using filled PTFE grades that incorporate materials like glass or carbon to improve strength and creep resistance.

Higher Initial Cost

PTFE gaskets are typically more expensive than common elastomeric gaskets like EPDM or neoprene. However, this higher initial cost is often justified by longer service life and reduced downtime in the aggressive environments where it excels.

Making the Right Choice for Your Application

Your final decision must be based on the primary demand of your system.

- If your primary focus is purity and compliance (Food, Pharma, Biotech): Choose a virgin or expanded PTFE gasket that meets FDA or other relevant sanitary standards.

- If your primary focus is aggressive chemical resistance (Chemical Processing): PTFE is your baseline choice; its near-universal inertness is its most valuable asset.

- If your primary focus is sealing older or imperfect flanges: An expanded PTFE (ePTFE) sheet gasket provides excellent conformability to ensure a tight seal.

- If your primary focus is high pressure and temperature: Be mindful of creep and consider a filled PTFE or an envelope gasket to gain mechanical strength while retaining chemical resistance.

Understanding these core principles empowers you to select a sealing solution with confidence, ensuring the safety and reliability of your operation.

Summary Table:

| Property | Benefit | Key Industries |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Chemical Processing, Petrochemical |

| High Purity | Non-toxic, FDA-compliant | Pharmaceuticals, Food & Beverage |

| Temperature Resistance | Stable from cryogenic to 250°C | Power Generation, Semiconductor |

| Conformability | Seals imperfect surfaces | Various industrial applications |

Need Reliable PTFE Sealing Solutions?

KINTEK specializes in manufacturing high-performance PTFE components (including seals, gaskets, liners, and labware) for semiconductor, medical, laboratory, and industrial applications. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact sealing solution your operation requires.

Contact KINTEK today to discuss your specific PTFE gasket needs and benefit from our expertise in chemical-resistant, pure, and temperature-stable sealing solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications