In essence, Teflon membranes contribute to experimental accuracy by creating a highly stable and non-interactive barrier between your sample and the laboratory equipment. Their unique properties—chemical inertness, thermal stability, and a low-friction surface—work together to prevent contamination, minimize sample loss, and ensure equipment performs consistently under demanding conditions.

The core reason Teflon (PTFE) is trusted in laboratories is its extreme non-reactivity. By refusing to chemically interact with samples, solvents, or extreme temperatures, it guarantees that the experimental results you observe are due to your variables, not a failure of your materials.

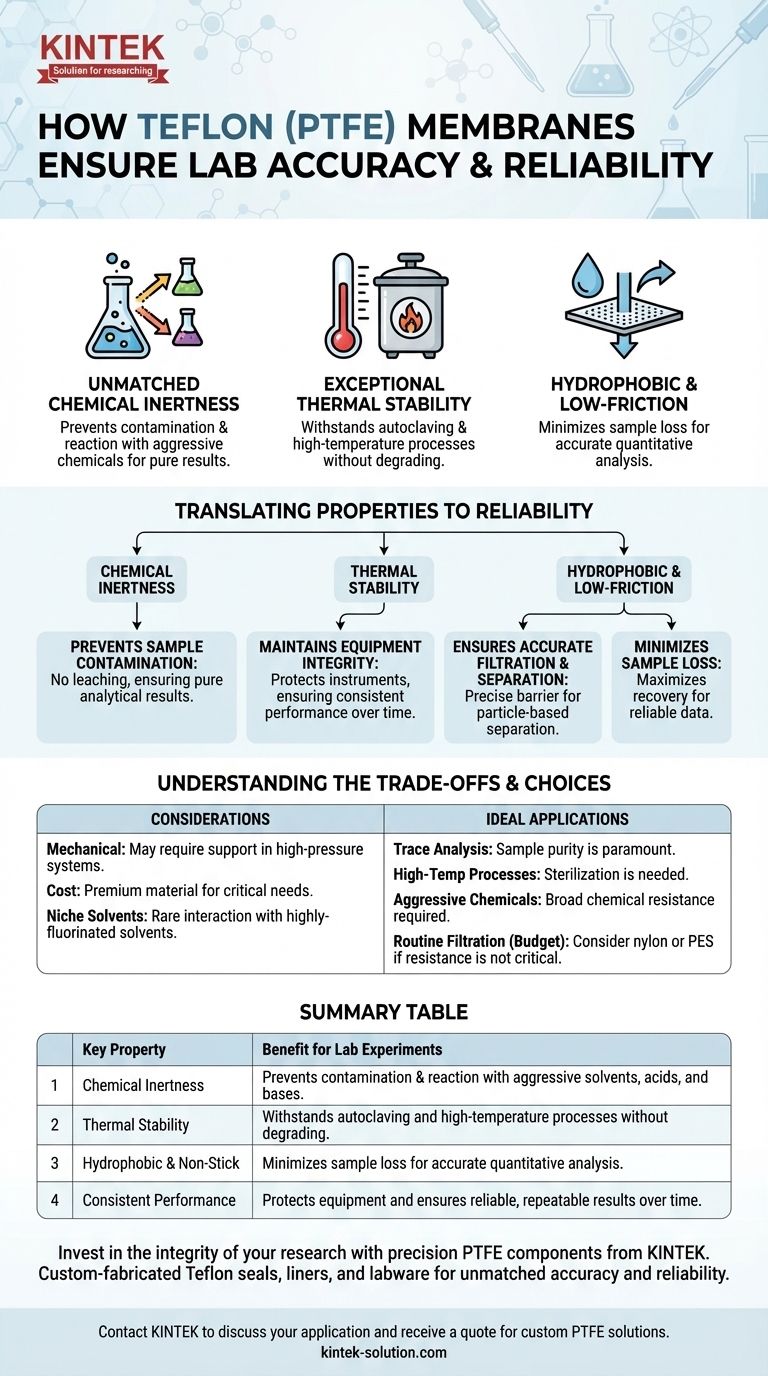

The Foundational Properties of Teflon (PTFE)

To understand why Teflon membranes are so reliable, we must first look at their fundamental material characteristics. These properties are not just beneficial; they are often essential for high-stakes research.

Unmatched Chemical Inertness

Teflon, or polytetrafluoroethylene (PTFE), is a fluoropolymer known for its exceptional resistance to a vast range of chemicals.

This inertness means the membrane will not degrade, react with, or leach impurities into your sample, preserving its original composition. This is critical for trace analysis and sensitive biological work.

Exceptional Thermal Stability

These membranes can withstand a wide temperature range without losing their structural integrity or mechanical properties.

This makes them suitable for processes involving extreme heat, such as autoclaving and sterilization, ensuring the material remains stable and reliable throughout the entire experimental workflow.

Hydrophobic and Low-Friction Surface

Teflon is inherently hydrophobic (water-repelling) and has one of the lowest coefficients of friction of any solid.

This non-stick quality is crucial for minimizing sample loss, as liquids and solids do not adhere to the surface. It ensures maximum sample recovery during filtration and precise, clean dispensing in liquid handling devices.

How These Properties Translate to Experimental Reliability

The theoretical properties of Teflon directly impact the day-to-day accuracy and repeatability of lab work. Each characteristic solves a common experimental problem.

Preventing Sample Contamination

Because Teflon does not react with acids, bases, or aggressive organic solvents, it provides a clean pathway for samples. This eliminates the risk of contamination from the equipment itself, ensuring analytical results are pure.

Ensuring Accurate Filtration and Separation

In applications like gas chromatography or sterile filtration, the membrane acts as a precise barrier. Its durability and consistent pore structure ensure that separation is based purely on physical properties (like particle size), not on chemical reactions with the filter.

Minimizing Sample Loss

The non-stick surface guarantees that the entire sample passes through the device, from filtration funnels to pipette tips. This is vital for quantitative experiments where even microscopic losses can skew results and lead to inaccurate conclusions.

Maintaining Equipment Integrity

Using a membrane that can endure harsh chemicals and high temperatures protects the longevity and performance of expensive laboratory instruments. This leads to more consistent performance over time, reducing variability between experiments.

Understanding the Trade-offs

While Teflon's properties are exceptional, no material is perfect for every scenario. An objective assessment requires acknowledging its limitations.

Mechanical Considerations

PTFE is a relatively soft material and can be susceptible to "creep" under sustained pressure. In high-pressure filtration systems, it often requires a rigid support structure to prevent deformation.

Cost vs. Necessity

Teflon is a premium polymer, and membranes made from it are often more expensive than alternatives like nylon or cellulose. Its use is most justified when chemical inertness and thermal stability are non-negotiable requirements.

Niche Solvent Interactions

While resistant to nearly everything, certain highly-fluorinated solvents can cause PTFE to swell. This is a rare consideration but is important for researchers working with specialized chemicals.

Making the Right Choice for Your Application

Selecting the correct membrane is a foundational step for generating trustworthy data. Base your decision on the most critical variable in your experiment.

- If your primary focus is sample purity or trace analysis: Teflon is the gold standard due to its unmatched chemical inertness.

- If your primary focus is high-temperature processes like sterilization: Teflon's thermal stability ensures the membrane will not fail.

- If your primary focus is working with aggressive solvents or mixed chemicals: Teflon's broad chemical resistance provides the safest and most reliable option.

- If your primary focus is routine aqueous filtration on a budget: Other materials like nylon or PES may be a more cost-effective choice if extreme chemical resistance is not needed.

Ultimately, choosing a material like Teflon is an investment in the integrity and reliability of your scientific results.

Summary Table:

| Key Property | Benefit for Lab Experiments |

|---|---|

| Chemical Inertness | Prevents contamination and reaction with aggressive solvents, acids, and bases. |

| Thermal Stability | Withstands autoclaving and high-temperature processes without degrading. |

| Hydrophobic & Non-Stick | Minimizes sample loss for accurate quantitative analysis. |

| Consistent Performance | Protects equipment and ensures reliable, repeatable results over time. |

Invest in the integrity of your research with precision PTFE components from KINTEK.

Whether you are working in the semiconductor, medical, laboratory, or industrial sectors, our custom-fabricated Teflon seals, liners, and labware are engineered to provide the unmatched chemical resistance and thermal stability your experiments demand. From initial prototypes to high-volume production, we ensure every component meets the highest standards for accuracy and reliability.

Contact KINTEK today to discuss your specific application and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- How are PTFE syringe filters modified for hydrophilic applications? Achieve Easy Filtration of Aqueous Solutions

- How do Teflon membranes enhance chemical resistance in laboratory equipment? Maximize Purity and Durability

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- In what ways are PTFE silicone septas versatile for pharmaceutical applications? Ensuring Sample Integrity from Discovery to QC

- How do the costs of PTFE and silicone septa compare? Understand the Value Beyond Price

- Why are PTFE-coated septums preferred in chromatography? Ensure Sample Integrity and Accurate Results

- What are the benefits of using a PTFE safety cover? Enhance Safety, Cut Costs & Mitigate Hazards

- What types of PTFE liners are available for bottle caps? Choose Between Solid PTFE or Composite Liners