At their core, PTFE/silicone septas are versatile because their dual-material construction provides a unique combination of chemical inertness and physical resilience. This allows them to be used reliably across the entire pharmaceutical lifecycle, from early-stage drug discovery and analytical testing to final quality assessment, without compromising sample integrity.

The true value of a PTFE/silicone septum isn't just its wide range of uses, but its ability to act as an invisible, protective barrier. It ensures that the sample you analyze is pure and that your results are accurate and defensible.

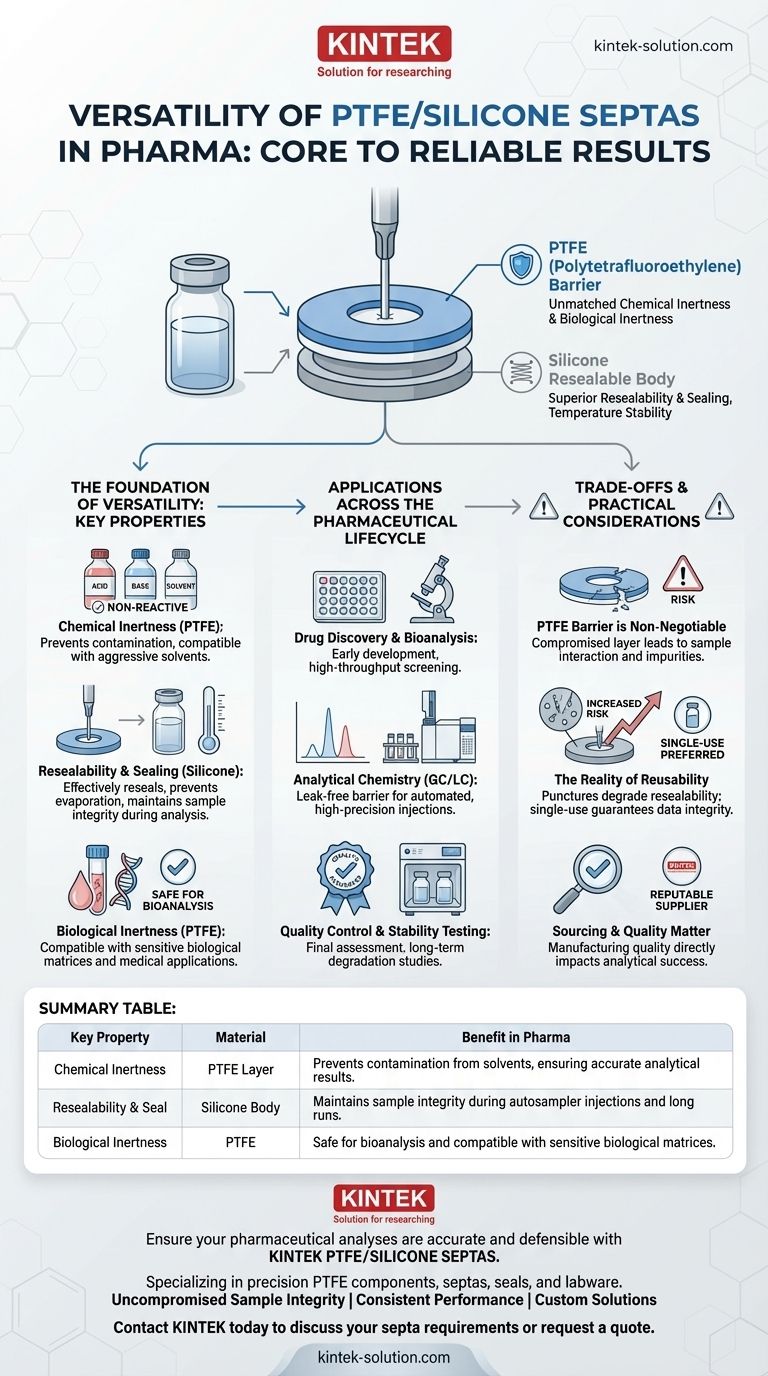

The Foundation of Versatility: Key Material Properties

The septum's versatility stems directly from the distinct roles played by its two components: a chemically resistant PTFE layer and a resealable silicone body.

Unmatched Chemical Inertness

The layer of PTFE (polytetrafluoroethylene) faces the sample. This material is exceptionally non-reactive.

PTFE is compatible with the acidic, alkaline, and aggressive organic solvents commonly used in pharmaceutical analysis. This prevents the septum from leaching contaminants into the sample or reacting with the drug formulation.

This inertness is critical for ensuring the accuracy of sensitive analyses, such as impurity identification or stability testing.

Superior Resealability and Sealing

The main body of the septum is made of silicone. This material provides a soft, elastic, and physically resilient seal for the vial.

When punctured by an autosampler needle, the silicone effectively reseals, preventing sample evaporation and atmospheric contamination. This is vital for maintaining sample concentration during long analytical runs.

Silicone also provides excellent temperature stability, maintaining its seal during heated or cooled chromatographic analyses.

Critical Biological Inertness

PTFE is a biologically inert material, meaning it does not react with biological tissues or fluids.

This property is essential for bioanalysis, where septas come into contact with sensitive biological matrices, and in medical applications where materials must be compatible with the human body.

Applications Across the Pharmaceutical Lifecycle

These fundamental properties allow PTFE/silicone septa to be trusted in a wide array of critical applications.

Drug Discovery and Bioanalysis

In early development, septas are used to seal vials for high-throughput screening and initial compound analysis. Their inertness ensures that potential drug candidates are not contaminated.

Analytical Chemistry (GC/LC)

Septas are a crucial component in gas and liquid chromatography (GC/LC). They form a leak-free, resealable barrier for autosampler vials.

This allows for automated, high-precision injections into the analytical instrument while protecting the sample from the external environment and preventing solvent loss.

Quality Control and Stability Testing

In final quality assurance, septas seal vials used for stability studies. These tests assess how a drug product degrades over time under various conditions.

The reliable seal ensures that any detected impurities are from the drug product itself, not from external contamination or interaction with the closure.

Understanding the Trade-offs and Practical Considerations

While highly effective, it is important to understand the practical limitations and considerations when using these septas to ensure reliable outcomes.

The PTFE Barrier is Non-Negotiable

The chemical resistance of the septum comes almost entirely from the thin PTFE layer. The underlying silicone is far less inert.

If the PTFE film is damaged, poorly manufactured, or not present, the silicone can absorb sample components or leach impurities, leading to compromised analytical results.

The Reality of Reusability

While some septas are marketed as reusable to reduce costs, this practice carries significant risk in a pharmaceutical setting.

Each puncture degrades the septum's ability to reseal perfectly, increasing the risk of evaporation or contamination. For critical analyses, single-use is the safest practice to guarantee data integrity.

Sourcing and Quality Matter

The performance of a septum is directly tied to its manufacturing quality. Poorly laminated PTFE/silicone, inconsistencies in thickness, or impure raw materials can all lead to analytical failures. Sourcing from a reputable supplier is essential.

Making the Right Choice for Your Application

Selecting the appropriate septum strategy depends entirely on the goal of your analysis.

- If your primary focus is trace-level impurity testing or regulated QC analysis: Always use a new, high-quality septum for each vial to eliminate any risk of cross-contamination or seal failure.

- If your primary focus is early-stage screening or routine process checks: Limited and carefully validated reuse may be considered, but you must be aware of the potential for compromised results.

- If you are working with highly aggressive solvents or performing long-term stability studies: Confirm the septum is specified for your conditions and prioritize a robust, single-use septum to ensure a perfect seal.

Ultimately, understanding how a PTFE/silicone septum works empowers you to protect your sample and trust your results.

Summary Table:

| Key Property | Material | Benefit in Pharma |

|---|---|---|

| Chemical Inertness | PTFE Layer | Prevents contamination from solvents, ensuring accurate analytical results. |

| Resealability & Seal | Silicone Body | Maintains sample integrity during autosampler injections and long runs. |

| Biological Inertness | PTFE | Safe for bioanalysis and compatible with sensitive biological matrices. |

Ensure your pharmaceutical analyses are accurate and defensible with high-quality PTFE/silicone septas from KINTEK.

At KINTEK, we specialize in manufacturing precision PTFE components, including septas, seals, liners, and labware, tailored for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. Our septas are engineered with superior lamination to provide the chemical resistance and reliable sealing your applications require—from drug discovery and bioanalysis to quality control and stability testing.

By choosing KINTEK, you benefit from:

- Uncompromised Sample Integrity: Our PTFE layer ensures non-reactivity with aggressive solvents.

- Consistent Performance: Precision manufacturing guarantees a perfect seal every time.

- Custom Solutions: We offer fabrication from prototypes to high-volume orders to meet your specific needs.

Protect your samples and trust your results. Contact KINTEK today to discuss your septa requirements or request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE syringe filters indispensable? For Superior Chemical Resistance and Sample Integrity

- What are the advantages of PTFE in pharmaceutical and biotech research? Ensure Purity and Prevent Contamination

- What are the characteristics of wide mouth PTFE laboratory bottles? Engineered for Extreme Chemical & Thermal Resistance

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- Why is the shelf life of PTFE/silicone septa a concern? Prevent Analytical Errors with Reliable Seals

- How does applying a fluoropolymer film improve pharmaceutical stoppers? Enhance Drug Safety and Stability

- How are PTFE stirrers and shafts typically constructed for industrial use? Choose the Right Method for Your Process

- What are the benefits of reusing HPLC autosampler vials with PTFE/silicone septa? Save Costs & Boost Lab Sustainability