At its core, reusing HPLC autosampler vials equipped with PTFE/silicone septa offers two primary benefits: significant cost savings and improved laboratory sustainability. These advantages are made possible by the septum's durable, self-sealing nature, but their viability is entirely dependent on maintaining septum integrity and employing rigorous cleaning protocols to prevent contamination.

The decision to reuse autosampler vials is not merely economic; it's a calculated risk assessment. While the material properties of PTFE/silicone septa make reuse possible, the non-negotiable demand for analytical accuracy means you must weigh the financial benefits against the potential for data-corrupting contamination.

The Foundation: Why Reuse is a Consideration

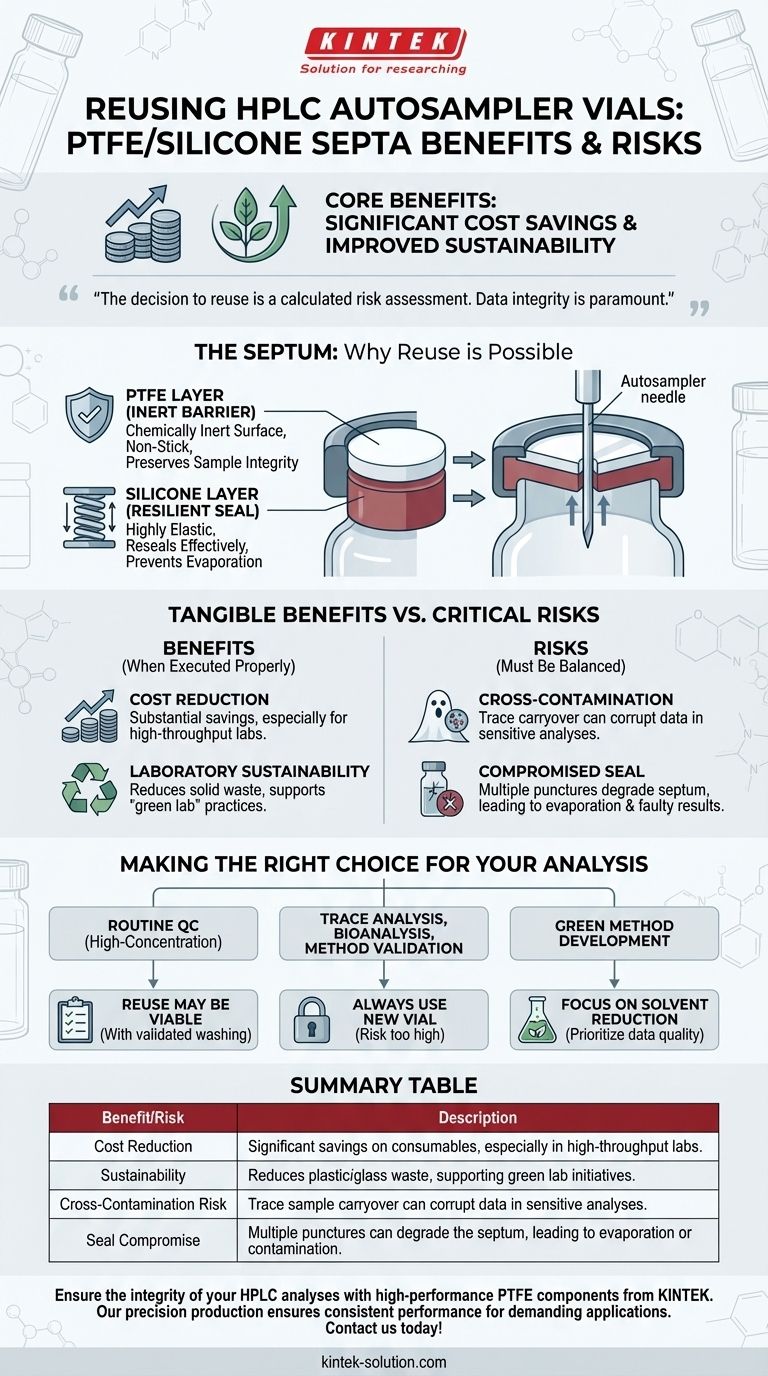

The unique construction of PTFE/silicone septa is what makes this discussion possible. The two materials work in tandem to provide a seal that is both chemically resistant and physically resilient, which are prerequisites for any potential reuse.

The Role of the PTFE Layer: An Inert Barrier

The PTFE (polytetrafluoroethylene) layer is the part of the septum that faces your sample. Its primary function is to provide a chemically inert surface.

This non-reactive barrier is critical for preventing any interaction between the septum and the sample, thereby preserving the sample's original composition and ensuring analytical integrity. The smooth, non-stick surface also helps minimize the adherence of sample residue.

The Role of the Silicone Layer: A Resilient Seal

The thicker silicone layer provides the mechanical function of the septum. It is highly elastic and compressible, allowing it to form a tight, secure seal against the vial rim.

When the autosampler needle punctures the septum, the silicone's resilience allows it to reseal effectively around the puncture site, preventing sample evaporation and protecting it from atmospheric contaminants.

The Tangible Benefits of Reuse

When executed properly, a vial reuse program can deliver clear advantages to a laboratory's budget and environmental footprint.

Significant Cost Reduction

Autosampler vials and caps are consumable items, and their costs can accumulate rapidly, especially in high-throughput labs.

Reusing vials, even just once or twice for non-critical applications, can translate into a substantial reduction in annual consumable spending.

Enhancing Laboratory Sustainability

The push for more sustainable "green lab" practices is a growing priority. Reducing the consumption of single-use plastics and glass is a key component of this effort.

By cleaning and reusing vials, laboratories can significantly decrease their solid waste output, contributing to a smaller environmental footprint.

Understanding the Trade-offs: The Risks of Reuse

The benefits of reuse are compelling, but they must be balanced against the serious risks involved. For an analytical chemist, data integrity is paramount, and improper reuse can jeopardize it.

The Primary Risk: Cross-Contamination

Even with thorough washing, trace amounts of a previous sample can adsorb onto the vial's glass surface or within the septum's puncture site.

For sensitive methods, particularly trace analyte analysis or mass spectrometry, this carryover can lead to ghost peaks, inaccurate quantification, and failed batches. The risk far outweighs the cost of a new vial.

The Threat of a Compromised Seal

A septum is not infinitely resealable. With each puncture, the material's integrity degrades slightly, a phenomenon known as coring.

After multiple injections, the septum may fail to seal properly. This can lead to sample evaporation, which concentrates the analyte and produces falsely high results, or allow airborne contaminants to enter the vial.

The Hidden Cost of Inaccurate Data

The cost of a single vial is minimal compared to the cost of troubleshooting a failed analysis, repeating experiments, or making a business decision based on faulty data. The time of a skilled analyst, the use of expensive solvents, and the wear on the HPLC system all represent a much greater investment than a new vial.

Making the Right Choice for Your Analysis

The decision to reuse vials should never be a blanket policy. It must be made on a case-by-case basis, guided by the specific requirements of the analytical method.

- If your primary focus is routine QC with high-concentration samples: Reuse may be a viable strategy, provided you have a validated and rigorously controlled vial washing procedure.

- If your primary focus is trace analysis, method validation, or bioanalysis: The risk of contamination is too high. Always use a new, certified-clean vial and septum for each sample.

- If your primary focus is developing a "green" method: Your efforts are better spent on reducing solvent consumption or scaling down the analysis rather than risking data quality by reusing vials in a critical application.

Ultimately, a disciplined assessment of your analytical goals will determine whether the economic benefits of reuse outweigh the potential scientific risks.

Summary Table:

| Benefit/Risk | Description |

|---|---|

| Cost Reduction | Significant savings on consumables, especially in high-throughput labs. |

| Sustainability | Reduces plastic/glass waste, supporting green lab initiatives. |

| Cross-Contamination Risk | Trace sample carryover can corrupt data in sensitive analyses. |

| Seal Compromise | Multiple punctures can degrade the septum, leading to evaporation or contamination. |

Ensure the integrity of your HPLC analyses with high-performance PTFE components from KINTEK.

While reusing vials can offer cost and sustainability benefits, the reliability of your data depends on the quality and integrity of your consumables. For labs in the semiconductor, medical, laboratory, and industrial sectors, KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that deliver the chemical inertness and durability required for demanding applications.

Whether you need standard parts or custom-fabricated prototypes and high-volume orders, our focus on precision production ensures consistent performance.

Contact us today to discuss how our PTFE solutions can enhance your lab's efficiency and data reliability. Get in touch

Visual Guide

Related Products

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What is PTFE and what are its basic properties? The Ultimate Guide to the High-Performance Polymer

- What are the features of PTFE laboratory bottles? Unmatched Chemical Resistance & Extreme Temperature Tolerance

- What temperature range can PTFE vials withstand? From -200°C to +260°C for Extreme Applications

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency