Applying a fluoropolymer film to a pharmaceutical stopper fundamentally transforms it from a simple rubber plug into a high-performance, inert barrier component. This lamination process dramatically improves the stopper's barrier properties, enhances its seal integrity, and, most critically, prevents the chemical components of the rubber from leaching into the drug product, thereby safeguarding its purity and stability.

The core function of a fluoropolymer film is to create a chemically inert barrier between the drug and the elastomer. This separation is the key to protecting sensitive modern medicines, like biologics, from contamination and degradation.

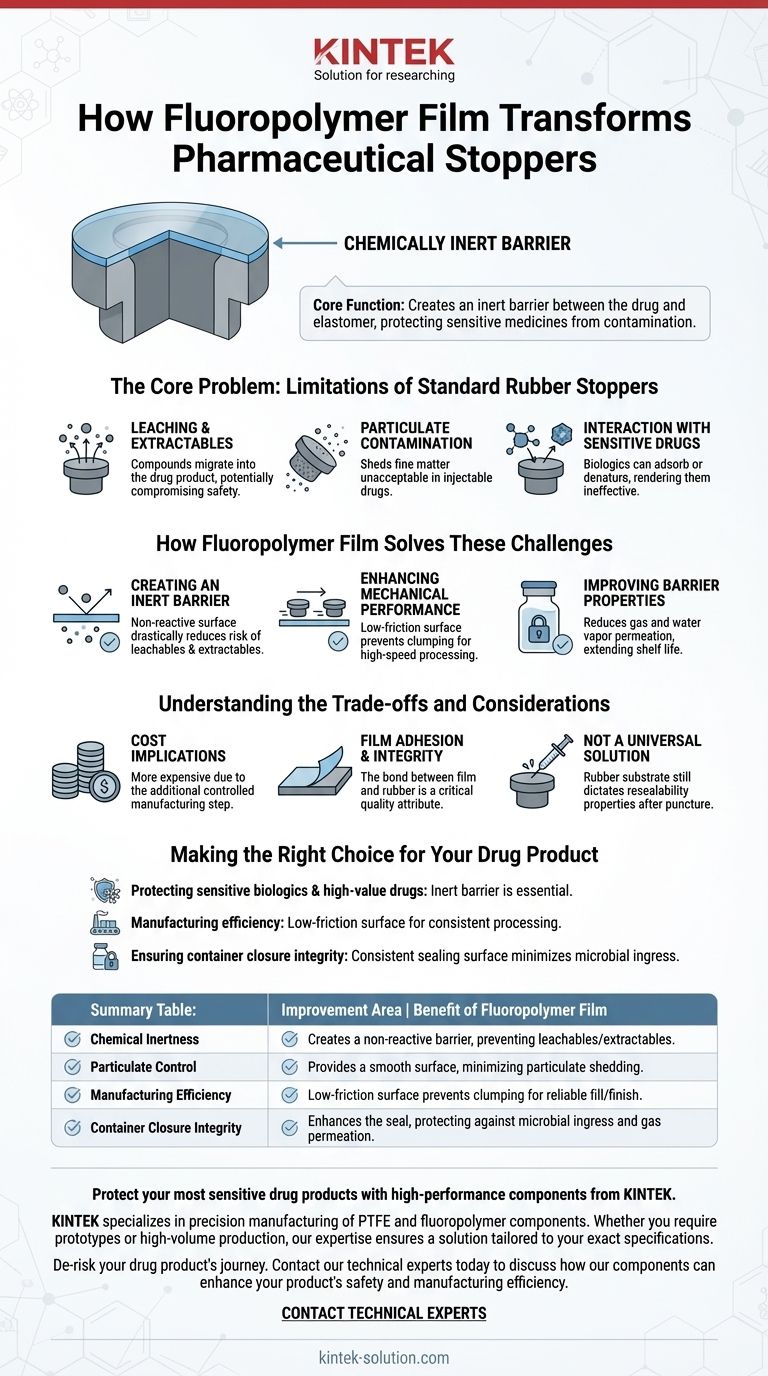

The Core Problem: Limitations of Standard Rubber Stoppers

To understand the value of the film, we must first recognize the inherent challenges of using standard elastomeric (rubber) stoppers in direct contact with a drug product.

The Risk of Leaching and Extractables

Elastomeric formulations contain various components, including polymers, vulcanizing agents, and fillers. Leachables are compounds that can migrate from the rubber into the drug product under normal storage conditions, potentially compromising its safety and efficacy.

Extractables are compounds that can be drawn out under more aggressive conditions, such as during an extraction study. Both represent a significant risk to product quality.

Particulate Contamination

Standard rubber stoppers can shed fine particulate matter. This contamination is unacceptable in injectable drug products and can lead to rejected batches and regulatory scrutiny.

Interaction with Sensitive Drugs

Many modern drugs, especially biologics and complex protein-based therapies, are highly sensitive. Direct contact with certain rubber compounds can cause the drug molecule to adsorb to the surface or denature, rendering it ineffective.

How Fluoropolymer Film Solves These Challenges

The film acts as a comprehensive solution to these problems by fundamentally changing the drug-contact surface of the stopper.

Creating an Inert Barrier

Fluoropolymers, such as Ethylene tetrafluoroethylene (ETFE) or Polytetrafluoroethylene (PTFE), are exceptionally non-reactive. By laminating a micro-thin layer of this film onto the stopper, you create a physical barrier that is chemically inert.

This inert surface effectively isolates the drug from the underlying rubber, drastically reducing the risk of leachables and extractables contaminating the formulation.

Enhancing Mechanical Performance

The film provides a very low coefficient of friction. This lubricity is critical for high-speed automated fill/finish lines, as it prevents stoppers from clumping or sticking during processing.

This smooth surface ensures stoppers are seated correctly and consistently within the vial, which is essential for achieving a reliable container closure seal.

Improving Barrier Properties

Beyond preventing leaching, the film enhances the stopper's ability to act as a barrier to the outside environment. It reduces the permeation of gases and water vapor, which helps maintain the drug's intended chemical environment and extend its shelf life.

Understanding the Trade-offs and Considerations

While highly effective, using film-laminated stoppers involves specific considerations that are important for any technical professional to understand.

Cost Implications

Applying a fluoropolymer film is an additional, highly controlled manufacturing step. Consequently, film-laminated stoppers are more expensive than their uncoated rubber counterparts. This cost must be weighed against the value and sensitivity of the drug product they protect.

Film Adhesion and Integrity

The bond between the film and the rubber substrate is a critical quality attribute. Any failure in this bond, such as delamination, would compromise the entire system. Manufacturers employ rigorous quality control to ensure this bond is permanent and robust.

Not a Universal Solution

While the film provides an inert barrier, the underlying rubber formulation still dictates the stopper's mechanical properties, such as its ability to reseal after being punctured by a needle. The complete component—film and elastomer—must be qualified to ensure it is appropriate for the specific drug application.

Making the Right Choice for Your Drug Product

The decision to use a fluoropolymer-filmed stopper should be based on a clear risk assessment of your product's needs.

- If your primary focus is protecting sensitive biologics or high-value drugs: The inert barrier provided by a fluoropolymer film is essential to prevent chemical interaction and ensure product stability.

- If your primary focus is manufacturing efficiency: The film's low-friction surface reduces stopper clumping and ensures consistent, trouble-free processing on high-speed fill/finish lines.

- If your primary focus is ensuring container closure integrity: The film provides a clean, consistent sealing surface that minimizes the risk of microbial ingress and maintains product sterility over its shelf life.

Ultimately, selecting a fluoropolymer-filmed stopper is a critical step in de-risking your drug product's journey from manufacturing to patient.

Summary Table:

| Improvement Area | Benefit of Fluoropolymer Film |

|---|---|

| Chemical Inertness | Creates a non-reactive barrier, preventing leachables/extractables from contaminating the drug product. |

| Particulate Control | Provides a smooth surface that minimizes particulate shedding from the rubber stopper. |

| Manufacturing Efficiency | Low-friction surface prevents clumping and ensures reliable performance on high-speed fill/finish lines. |

| Container Closure Integrity | Enhances the seal against the vial, protecting against microbial ingress and gas permeation. |

Protect your most sensitive drug products with high-performance components from KINTEK.

For pharmaceutical, medical, and laboratory applications, the integrity of your container closure system is non-negotiable. KINTEK specializes in the precision manufacturing of PTFE and other fluoropolymer components, including seals, liners, and custom labware.

We understand the critical need for chemically inert, reliable barriers that safeguard product purity and stability. Whether you require prototypes or high-volume production runs, our expertise in custom fabrication ensures you get a solution tailored to your exact specifications.

De-risk your drug product's journey. Contact our technical experts today to discuss how our components can enhance your product's safety and manufacturing efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of selecting the appropriate PTFE-coated septum for chromatography? Ensure Accurate & Reproducible Results

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision

- What are the key properties of PTFE that make it suitable for labware applications? Ensure Lab Integrity with Superior Material

- What other PTFE lab accessories are commonly used? Essential Tools for Chemical Resistance & Purity

- What are the key requirements for materials used in chemical laboratories? Ensure Safety and Data Integrity

- What are the key features of PTFE reagent bottles? Superior Chemical Resistance and Durability

- What are the key properties of PTFE syringe filters? Unlock Unmatched Chemical Resistance and Versatility

- What advantages do PTFE syringe filters offer in laboratory settings? Unmatched Chemical Resistance & Purity