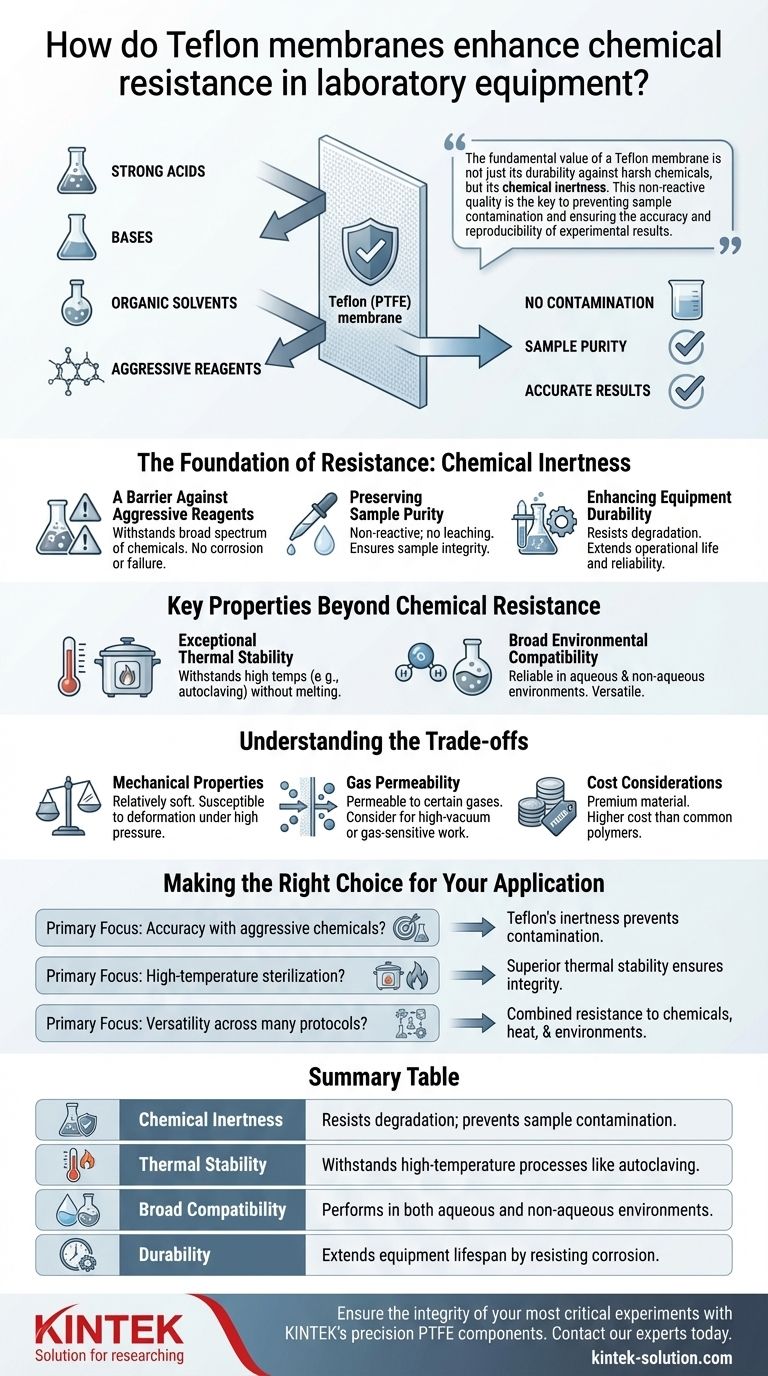

Teflon membranes enhance chemical resistance in laboratory equipment by being fundamentally inert. As a synthetic fluoropolymer known as PTFE, Teflon does not react with or degrade when exposed to a vast range of aggressive substances, including strong acids, bases, and organic solvents. This non-reactive quality preserves the integrity of both the equipment and the scientific samples being processed.

The fundamental value of a Teflon membrane is not just its durability against harsh chemicals, but its chemical inertness. This non-reactive quality is the key to preventing sample contamination and ensuring the accuracy and reproducibility of experimental results.

The Foundation of Resistance: Chemical Inertness

The exceptional performance of Teflon, or Polytetrafluoroethylene (PTFE), stems from its unique molecular structure. This structure is responsible for the properties that make it indispensable in demanding laboratory environments.

A Barrier Against Aggressive Reagents

Teflon’s core strength is its ability to withstand chemical attack. It is highly resistant to a broad spectrum of chemicals that would degrade lesser materials.

This includes strong acids, bases, solvents, and a wide variety of organic compounds. This ensures equipment can be used for diverse applications without fear of corrosion or failure.

Preserving Sample Purity

Because the membrane is non-reactive, it does not leach chemicals or impurities into the sample passing through it. This is critical for maintaining the purity of experimental materials.

This quality guarantees that the results of an analysis or experiment are due to the sample itself, not contamination from the equipment.

Enhancing Equipment Durability

By resisting chemical degradation, Teflon membranes extend the operational life of the laboratory equipment they are part of. This leads to greater reliability and lower long-term costs.

Key Properties Beyond Chemical Resistance

Teflon’s utility is amplified by other intrinsic properties that make it uniquely suited for laboratory work. These characteristics work in concert with its chemical resistance.

Exceptional Thermal Stability

Teflon membranes can withstand very high temperatures without losing their structural integrity or chemical resistance.

This makes them ideal for processes that involve extreme heat, such as autoclaving and high-temperature sterilization, where other polymers would melt or warp.

Broad Environmental Compatibility

These membranes perform reliably in both aqueous (water-based) and non-aqueous environments.

This versatility allows a single piece of equipment to be used for a wide range of experimental protocols, from biological filtration to organic solvent separation.

Understanding the Trade-offs

While Teflon offers unparalleled chemical and thermal performance, it's essential to understand its specific characteristics to use it effectively. No material is perfect for every single application.

Mechanical Properties

Teflon is a relatively soft material. While chemically robust, it can be more susceptible to scratching or mechanical deformation under very high pressures compared to rigid materials.

Gas Permeability

While an excellent barrier to liquids, PTFE membranes can be permeable to certain gases. This is a factor to consider in high-vacuum applications or when working with highly gas-sensitive experiments.

Cost Considerations

The advanced properties of Teflon mean it is often a premium material. Its cost is typically higher than that of other common membrane polymers like nylon or polypropylene.

Making the Right Choice for Your Application

Selecting the right membrane material hinges on the specific demands of your work. The decision to use Teflon should be based on a clear understanding of your experimental priorities.

- If your primary focus is accuracy with aggressive chemicals: Teflon's inertness is non-negotiable, as it is the best way to prevent sample contamination from leached materials.

- If your primary focus is high-temperature sterilization: Its superior thermal stability ensures the membrane's integrity through processes like autoclaving where other materials would fail.

- If your primary focus is versatility across many protocols: Teflon's combined resistance to chemicals, heat, and both aqueous and non-aqueous solvents makes it the most adaptable choice.

Ultimately, choosing Teflon is an investment in the reliability and integrity of your experimental outcomes.

Summary Table:

| Property | Benefit for Laboratory Equipment |

|---|---|

| Chemical Inertness | Resists degradation from strong acids, bases, and solvents; prevents sample contamination. |

| Thermal Stability | Withstands high-temperature processes like autoclaving without losing integrity. |

| Broad Compatibility | Performs reliably in both aqueous and non-aqueous environments. |

| Durability | Extends equipment lifespan by resisting chemical corrosion. |

Ensure the integrity of your most critical experiments with KINTEK's precision PTFE components.

Our chemically inert Teflon seals, liners, and labware are engineered to protect your samples and equipment from aggressive reagents, guaranteeing accurate, reproducible results. Whether you require a custom prototype or a high-volume order for the semiconductor, medical, or industrial sectors, we deliver the precision and reliability your lab demands.

Contact our experts today to discuss your specific application needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability