In essence, PTFE-lined bottle caps provide a chemically inert, non-reactive, and thermally stable seal for storing sensitive or aggressive substances. Their key features are exceptional resistance to chemicals like strong acids and solvents, a very wide operating temperature range (-200°C to +250°C), and the ability to be sterilized and reused, ensuring the absolute integrity of the container's contents.

The decision to use a PTFE-lined cap stems from a single, critical need: to create a completely non-reactive barrier between the stored substance and the outside environment, guaranteeing that the sample remains pure and the cap remains intact.

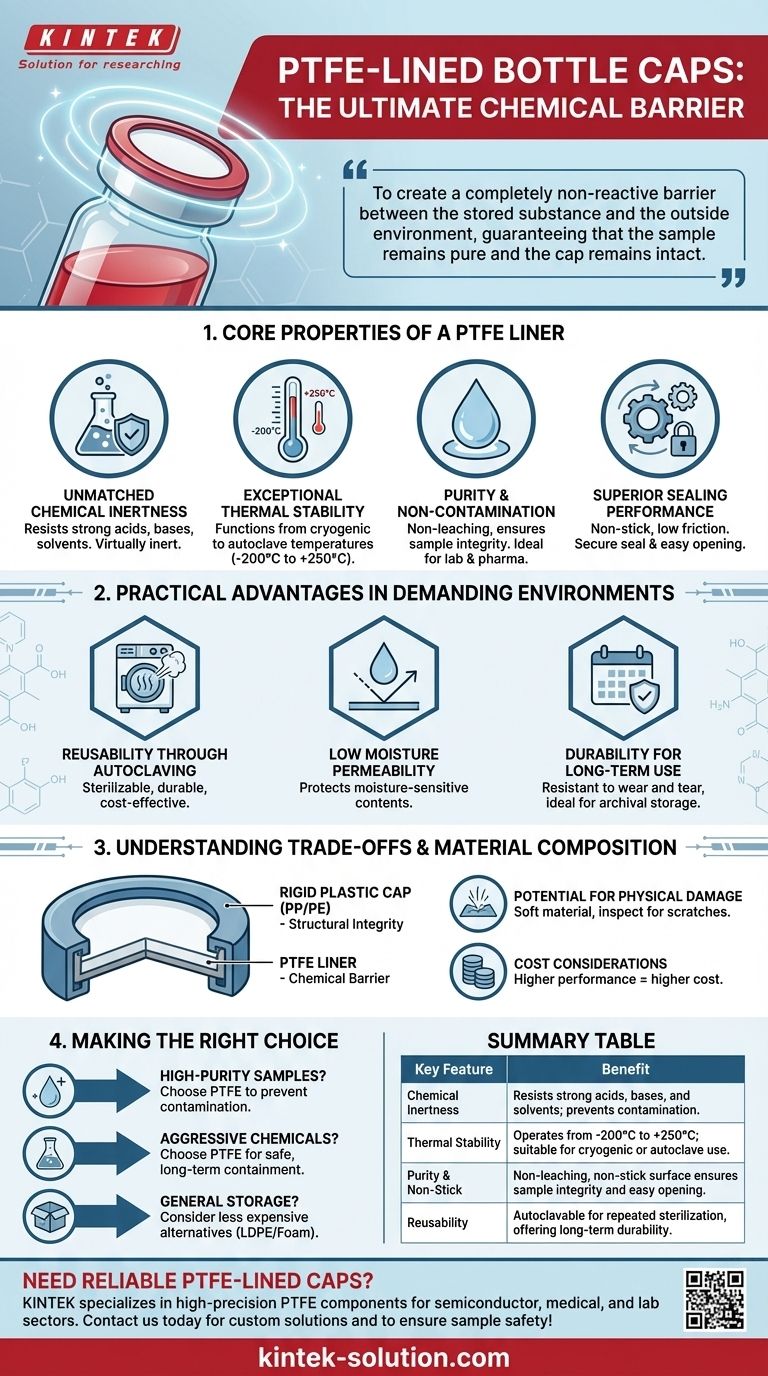

The Core Properties of a PTFE Liner

To understand why PTFE-lined caps are specified for demanding applications, we must first examine the core properties of Polytetrafluoroethylene (PTFE) itself. This material is engineered for performance in environments where lesser materials would fail.

Unmatched Chemical Inertness

The defining feature of PTFE is its extreme chemical resistance. It is virtually inert and does not react with the vast majority of substances.

This includes strong acids, bases, aggressive solvents, and other corrosive chemicals. This property ensures that the cap liner will not degrade or dissolve when in contact with the container's contents.

Exceptional Thermal Stability

PTFE liners maintain their integrity across an incredibly broad temperature range, typically from -200°C to +250°C (-328°F to +482°F).

This allows them to be used for storing samples in cryogenic freezers or for applications involving high-temperature sterilization without becoming brittle or melting.

Purity and Non-Contamination

Because PTFE is so inert, it will not leach chemicals into the stored substance. This is paramount in laboratory, pharmaceutical, and environmental testing.

Using a PTFE liner guarantees that the sample's purity is maintained, preventing contamination that could invalidate research results or compromise a product's quality.

Superior Sealing Performance

PTFE has a very low coefficient of friction, giving it a non-stick surface.

This property ensures a tight, secure seal while also preventing the cap from binding or sticking to the container, making it easy to open and close even after long-term storage.

Practical Advantages in Demanding Environments

The inherent properties of PTFE translate directly into tangible benefits for scientific, medical, and industrial use. These caps are not just for containment; they are a tool for ensuring reliability and repeatability.

Reusability Through Autoclaving

These caps are fully autoclavable, meaning they can be repeatedly sterilized with high-pressure steam without damaging the liner's structure or performance.

This makes them a durable and cost-effective choice for laboratory environments where sterile conditions are essential.

Low Moisture Permeability

The liner provides an excellent barrier against moisture vapor transmission. This protects hygroscopic (water-absorbing) or moisture-sensitive contents from degradation due to environmental humidity.

Durability for Long-Term Use

Designed for demanding settings, PTFE-lined caps are highly resistant to wear and tear. They provide a reliable seal over long periods, making them ideal for archival sample storage.

Understanding the Trade-offs and Material Composition

While highly effective, it's important to understand the complete picture of how these caps are constructed and where their limitations lie.

The Liner vs. The Cap

The critical component is the PTFE liner, which is the thin disc that makes direct contact with the container's opening.

The cap itself is typically made from a different, more rigid plastic like polypropylene (PP) or polyethylene (PE). The cap provides the structural integrity, while the liner provides the chemical barrier.

Potential for Physical Damage

While chemically robust, PTFE is a relatively soft material. A scratch or gouge in the liner from improper handling can compromise the seal.

A compromised liner can create a pathway for chemical attack or sample contamination, defeating the purpose of using a high-performance cap. Always inspect liners before critical use.

Cost Considerations

PTFE is a high-performance polymer, and as a result, these caps are typically more expensive than simpler alternatives like unlined caps or those with foam or rubber liners. Their cost is justified by the superior protection and reliability they offer.

Making the Right Choice for Your Application

Selecting the correct cap is a crucial step in ensuring the safety and integrity of your work. Your primary goal will determine if a PTFE liner is the appropriate choice.

- If your primary focus is preserving high-purity samples: The non-leaching, inert nature of PTFE makes it the superior choice to prevent contamination.

- If your primary focus is storing aggressive or corrosive chemicals: PTFE's exceptional chemical resistance provides the safest and most reliable long-term containment.

- If your primary focus is cost-effectiveness for general storage: A less expensive cap with a different liner (like LDPE or foam) may be sufficient for non-reactive or non-sensitive substances.

Ultimately, choosing a PTFE-lined cap is an investment in certainty for your most critical applications.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents; prevents contamination. |

| Thermal Stability | Operates from -200°C to +250°C; suitable for cryogenic or autoclave use. |

| Purity & Non-Stick | Non-leaching, non-stick surface ensures sample integrity and easy opening. |

| Reusability | Autoclavable for repeated sterilization, offering long-term durability. |

Need reliable PTFE-lined caps for your critical applications?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We ensure the chemical integrity and purity of your samples with components designed for demanding environments.

Whether you require custom fabrication from prototypes to high-volume orders, our expertise guarantees a perfect fit for your needs.

Contact us today to discuss your specific requirements and ensure the safety of your most sensitive substances!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications