At its core, Polytetrafluoroethylene (PTFE) enhances machinery durability and efficiency through one primary characteristic: an exceptionally low coefficient of friction. This property drastically reduces the resistance between moving parts, which in turn minimizes wear and tear, lowers energy consumption, and allows equipment to operate under more demanding conditions.

The true value of PTFE lies in a powerful chain reaction. Its inherent slipperiness directly combats friction, which simultaneously preserves the physical integrity of components (enhancing durability) and reduces the energy wasted to overcome resistance (improving efficiency).

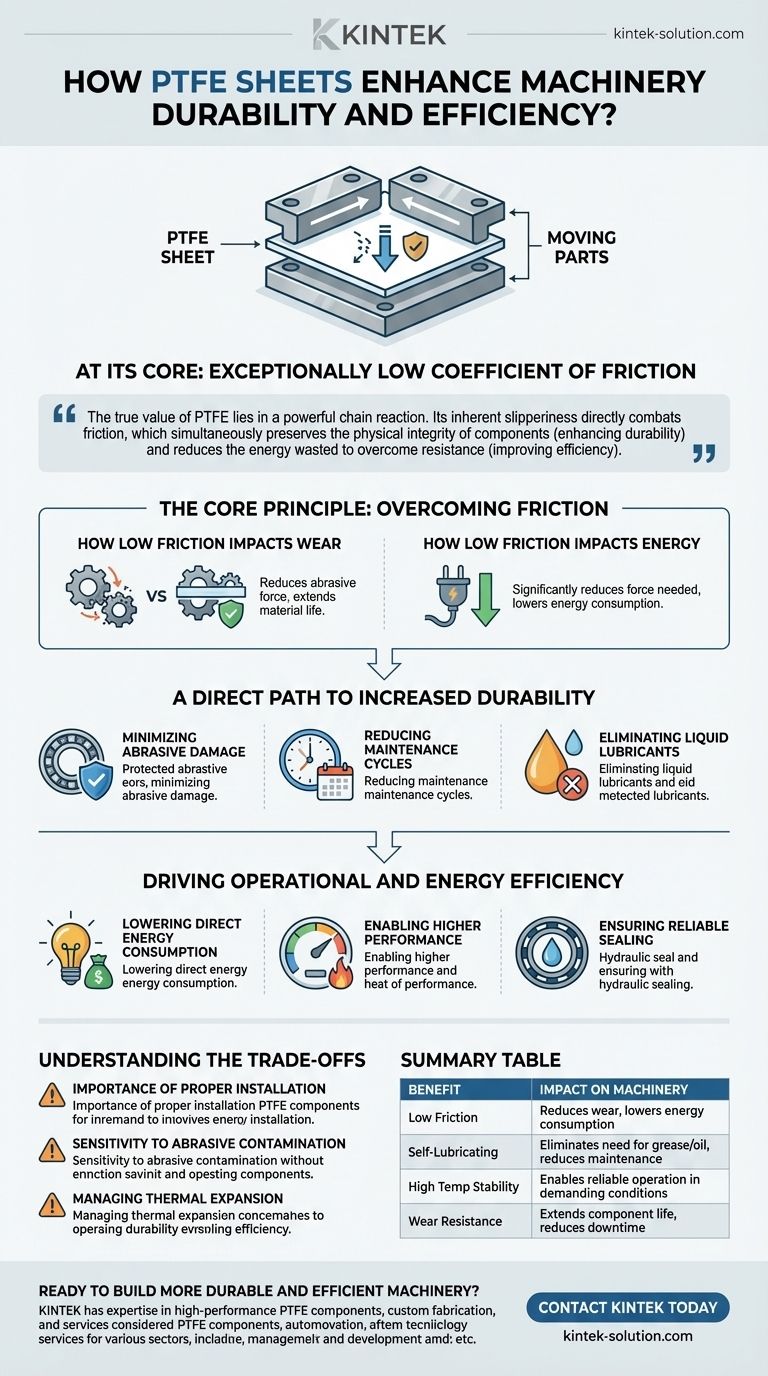

The Core Principle: Overcoming Friction

The fundamental reason PTFE is so effective in industrial applications is its unique molecular structure, which gives it one of the lowest coefficients of friction of any solid material known.

How Low Friction Impacts Wear

When two surfaces move against each other, friction creates abrasive force that physically wears down the materials. By introducing a PTFE sheet, washer, or seal between these surfaces, you create a self-lubricating barrier that allows parts to slide past each other with minimal resistance.

How Low Friction Impacts Energy

Friction is a force that machinery must overcome using energy. By significantly reducing this force, PTFE allows machinery to perform the same amount of work with less power. This directly translates to lower energy consumption and operational costs.

A Direct Path to Increased Durability

Introducing PTFE into a mechanical system is a direct strategy for extending its operational life and reducing the frequency of costly interventions.

Minimizing Abrasive Damage

In applications involving gears, bearings, and sliding shafts, PTFE acts as a sacrificial, low-wear surface. It protects more critical and expensive metal components from grinding against each other, dramatically extending their service life.

Reducing Maintenance Cycles

Components that last longer require less frequent replacement. Machinery using PTFE seals and bearings often benefits from extended maintenance intervals and warranties, leading to less downtime and lower long-term labor costs.

Eliminating Liquid Lubricants

In many cases, the self-lubricating nature of PTFE eliminates the need for grease or oil. This creates a cleaner operating environment and removes the maintenance task of re-lubrication, making it ideal for maintenance-free designs.

Driving Operational and Energy Efficiency

Efficiency gains from using PTFE are not theoretical; they are measurable improvements in output, speed, and energy use.

Lowering Direct Energy Consumption

Machinery parts moving with less resistance consume less electricity or fuel. This reduction in energy waste leads to direct cost savings and a lower environmental footprint over the equipment's lifespan.

Enabling Higher Performance

Because PTFE generates very little frictional heat and is stable at high temperatures, it enables machinery to operate safely at higher speeds. This allows for greater process efficiency and throughput without risking premature component failure.

Ensuring Reliable Sealing

In dynamic applications like seals, PTFE's low friction and wear resistance ensure a consistent and reliable seal over a long period. This prevents leaks and maintains operational pressures, which is critical for consistent machine performance.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Understanding its limitations is key to successful implementation.

The Importance of Proper Installation

The performance of a PTFE sheet or component is highly dependent on correct installation. The mating surface must be properly prepared and smooth to prevent tearing or accelerated wear of the softer PTFE material.

Sensitivity to Abrasive Contamination

PTFE's relative softness makes it susceptible to damage from hard, abrasive particles. In dirty or contaminated environments, proper system filtration is necessary to protect the PTFE surfaces from being scored or embedded with debris.

Managing Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. In applications with wide temperature swings, designs must account for this expansion and contraction to maintain proper clearances and prevent mechanical stress.

Making the Right Choice for Your Goal

Applying PTFE effectively requires aligning its benefits with your specific engineering or operational objectives.

- If your primary focus is reducing maintenance costs and downtime: Prioritize PTFE for its ability to dramatically extend the service life of wear-prone components like seals, bearings, and slide plates.

- If your primary focus is improving energy efficiency: Target applications with high-speed or continuous motion, where PTFE's low friction will provide the most significant reduction in energy consumption.

- If your primary focus is designing for high-performance or clean environments: Leverage PTFE's ability to handle extreme temperatures and eliminate the need for liquid lubricants, simplifying design and preventing contamination.

Ultimately, integrating PTFE is a strategic decision to build more robust, efficient, and reliable machinery from the inside out.

Summary Table:

| Benefit | Impact on Machinery |

|---|---|

| Low Friction | Reduces wear, lowers energy consumption |

| Self-Lubricating | Eliminates need for grease/oil, reduces maintenance |

| High Temp Stability | Enables reliable operation in demanding conditions |

| Wear Resistance | Extends component life, reduces downtime |

Ready to build more durable and efficient machinery?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom sheets, seals, liners, and labware. Our precision production and custom fabrication services, from prototypes to high-volume orders, are designed to meet the exacting demands of the semiconductor, medical, laboratory, and industrial sectors.

Let us help you integrate PTFE solutions that reduce friction, extend equipment life, and lower your operational costs.

Contact KINTEK today for a consultation and see how our expertise can benefit your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the disadvantages of PTFE Lined Globe Valves? Key Limitations to Consider

- What are some variations of control valve designs? A Guide to Linear vs. Rotary Motion Valves

- How do PTFE-lined valves compare to traditional metallic valves? Maximize Performance in Corrosive Applications

- What are the key features of PTFE sliding elastomeric bearings? Essential for Bridge and Structural Movement

- What is a Teflon seal and what material is it made from? Unlock Superior Performance in Harsh Environments

- What makes ePTFE sheets a preferred material in the food, beverage, and pharmaceutical sectors? Ensuring Product Purity and Safety

- What are the main advantages of using Teflon sheets in engineering? Boost Efficiency & Durability

- How do the non-stick properties of PTFE oil seals contribute to their performance? Ensure Long-Term Reliability in Harsh Conditions