At their core, PTFE sliding elastomeric bearings are composite devices engineered to solve two fundamental structural challenges at once. They combine the compressive strength and rotational flexibility of a traditional elastomeric bearing with an integrated, low-friction sliding surface made of Polytetrafluoroethylene (PTFE), allowing them to support massive vertical loads while permitting significant horizontal movement and angular rotation.

The key innovation of a PTFE sliding elastomeric bearing is the separation of duties: the elastomeric pad manages vertical loads and rotation, while the specialized PTFE layer handles large, low-friction horizontal sliding. This dual-function design makes it a highly efficient solution for modern bridges and complex structures.

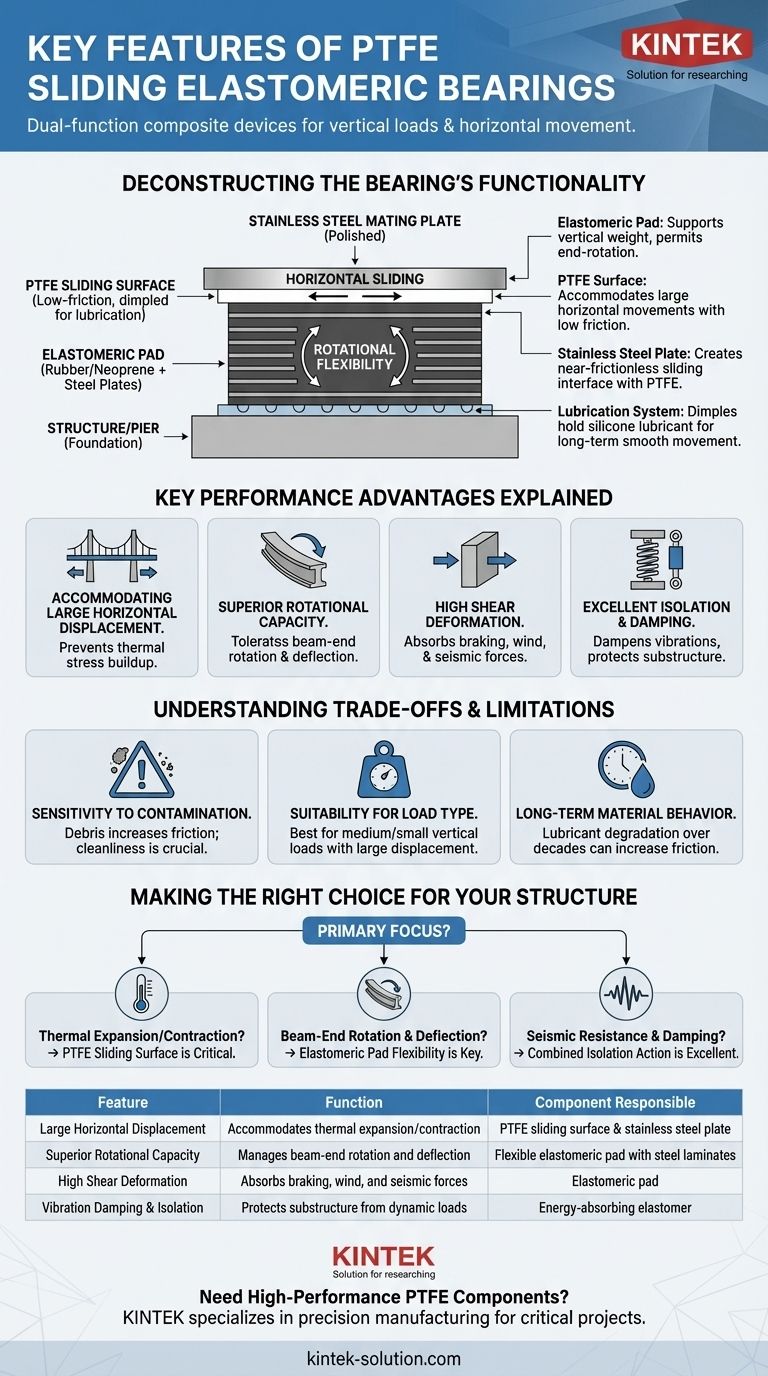

Deconstructing the Bearing's Functionality

To understand the features, we must first understand the components. These bearings are a layered system where each part has a distinct role.

The Elastomeric Pad

The foundation of the bearing is the elastomeric pad, typically made of natural rubber or neoprene and reinforced with internal steel plates. Its primary job is to support the immense vertical weight of the superstructure. Its inherent flexibility also allows it to deform and accommodate the slight end-rotation of a beam as it deflects under load.

The PTFE Sliding Surface

Bonded to the top of the elastomeric pad is a thin sheet of PTFE, a material renowned for its extremely low coefficient of friction. This layer is the key to accommodating large horizontal movements, such as those caused by thermal expansion and contraction, with minimal stress transferred to the piers and abutments.

The Stainless Steel Mating Plate

The PTFE does not slide against concrete. Instead, it slides against a highly polished stainless steel plate anchored to the structure's underside. This pairing of PTFE and polished steel is what creates the near-frictionless sliding interface.

The Lubrication System

To ensure consistently smooth movement over decades, the PTFE surface is often manufactured with small, recessed dimples. These dimples act as reservoirs, holding a silicone-based lubricant that reduces the initial friction and guarantees performance for the life of the bearing.

Key Performance Advantages Explained

The synergy between these components produces a set of powerful functional features critical for structural integrity and longevity.

Accommodating Large Horizontal Displacement

The primary advantage is the bearing's ability to permit significant horizontal sliding. The low-friction PTFE surface allows the bridge deck or superstructure to expand and contract freely, preventing the buildup of dangerous thermal stresses.

Superior Rotational Capacity

The elastomeric pad's flexibility gives the bearing the ability to tolerate beam-end rotation. As a bridge girder flexes under the weight of traffic, its ends rotate slightly. The bearing deforms to absorb this movement, preventing localized stress concentrations.

High Shear Deformation

Beyond simple sliding, the elastomer itself can deform horizontally (shear). This capacity to accommodate large shear deformation helps absorb horizontal forces from braking, wind, and seismic activity.

Excellent Isolation and Damping

The rubber in the elastomeric pad naturally dampens vibrations and absorbs impact energy from live loads (traffic) and seismic events. This isolation effect protects the substructure and enhances the overall durability and stability of the bridge.

Understanding the Trade-offs and Limitations

While highly effective, these bearings are not without constraints that must be considered in the design phase.

Sensitivity to Contamination

The performance of the sliding surface is highly dependent on its cleanliness. If dirt, sand, or construction debris gets between the PTFE and the stainless steel plate, it can score the surfaces, increasing friction and impeding free movement.

Suitability for Load Type

These bearings are exceptionally well-suited for structures with large displacements under medium or small vertical loads. For structures with extremely high vertical loads, other bearing types, such as pot bearings, may be a more appropriate choice.

Long-Term Material Behavior

While designed for durability, the lubricant within the PTFE dimples can degrade or be displaced over a very long service life, potentially leading to a gradual increase in the coefficient of friction. This is a critical factor in long-term maintenance and inspection plans.

Making the Right Choice for Your Structure

Selecting the right bearing depends entirely on the specific demands of the structure.

- If your primary focus is accommodating large thermal expansion and contraction: The PTFE sliding surface is the most critical feature, providing a reliable, low-friction mechanism for horizontal movement.

- If your primary focus is managing beam-end rotation and deflection: The flexibility of the steel-reinforced elastomeric pad is the key, allowing for angular changes without inducing harmful stress.

- If your primary focus is seismic resistance or dynamic load damping: The combined action of the sliding surface and the energy-absorbing properties of the elastomer provides an excellent isolation system.

By expertly combining two distinct material properties, PTFE sliding elastomeric bearings offer a sophisticated and reliable solution to the complex movements inherent in modern structures.

Summary Table:

| Feature | Function | Component Responsible |

|---|---|---|

| Large Horizontal Displacement | Accommodates thermal expansion/contraction | PTFE sliding surface & stainless steel plate |

| Superior Rotational Capacity | Manages beam-end rotation and deflection | Flexible elastomeric pad with steel laminates |

| High Shear Deformation | Absorbs braking, wind, and seismic forces | Elastomeric pad |

| Vibration Damping & Isolation | Protects substructure from dynamic loads | Energy-absorbing elastomer |

Need High-Performance PTFE Components for Your Project?

KINTEK specializes in the precision manufacturing of PTFE components, including the specialized materials essential for high-performance applications like structural bearings. Our expertise in custom fabrication ensures you get reliable, durable parts tailored to your exact specifications, from prototypes to high-volume orders.

Let us provide the material excellence your critical projects demand. Contact our team today to discuss your needs for the semiconductor, medical, laboratory, or industrial sectors.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support