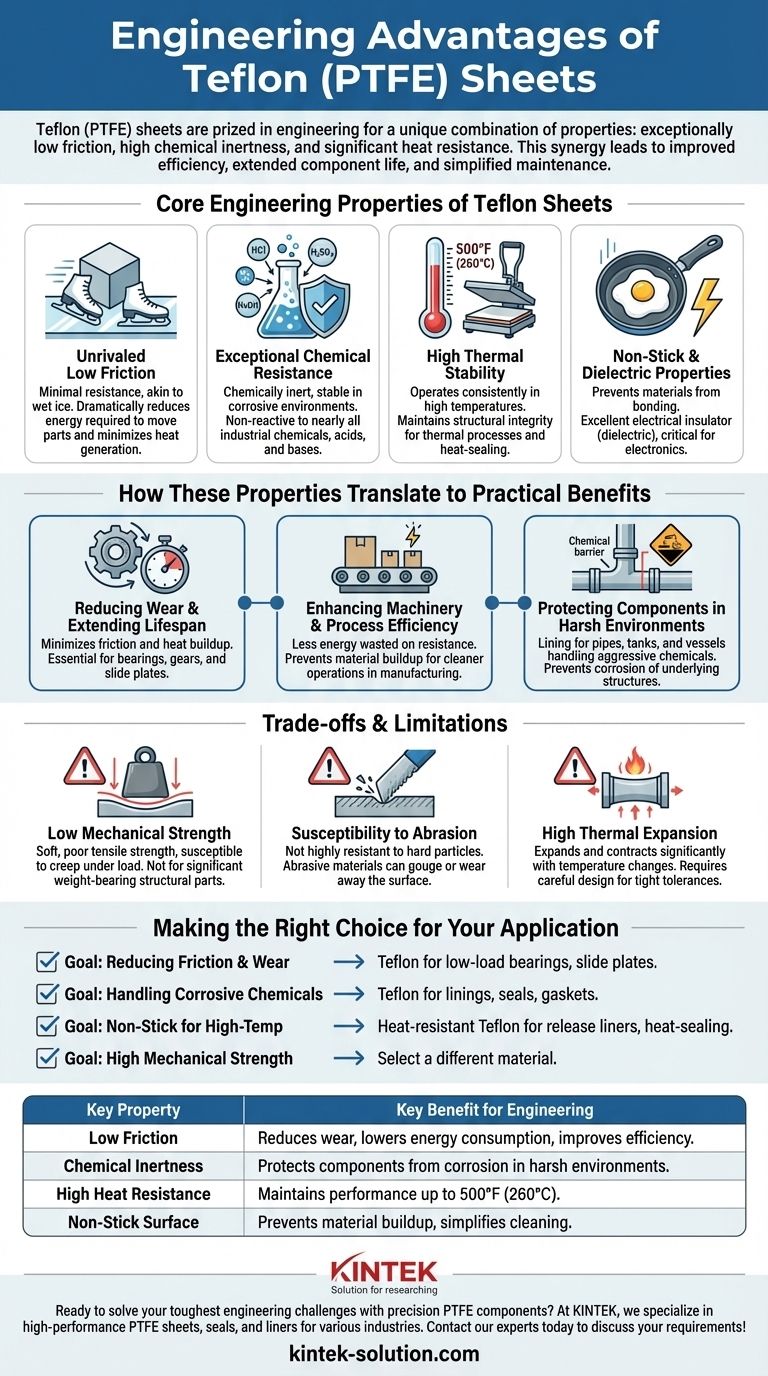

In engineering applications, Teflon (PTFE) sheets are prized for a unique combination of properties. Their value stems from an exceptionally low coefficient of friction, high chemical inertness, and significant heat resistance. This combination directly translates to improved machinery efficiency, extended component life, and simplified maintenance in a wide range of demanding environments.

Teflon's true advantage is not found in a single feature, but in the synergy of its properties. The combination of a non-stick, low-friction surface with profound chemical and thermal resilience allows it to solve complex engineering challenges where other materials would quickly fail.

The Core Engineering Properties of Teflon Sheets

To leverage Teflon effectively, it's crucial to understand the fundamental properties that drive its performance. These characteristics work together to create its unique value proposition in mechanical and process engineering.

Unrivaled Low Friction

Teflon, or Polytetrafluoroethylene (PTFE), has one of the lowest coefficients of friction of any known solid material. This is often compared to the friction of wet ice on wet ice.

This property means objects can slide across its surface with minimal resistance. This dramatically reduces the energy required to move parts and minimizes the generation of heat from friction.

Exceptional Chemical Resistance

Teflon is chemically inert, meaning it is non-reactive to nearly all industrial chemicals, acids, and bases. This makes it an incredibly stable material for use in corrosive environments.

Its molecular structure is extremely stable, preventing chemicals from breaking it down. This ensures purity in processes and protects underlying components from corrosive damage.

High Thermal Stability

Teflon sheets can operate consistently in high-temperature environments, often withstanding continuous service temperatures up to 500°F (260°C).

Unlike many plastics that would melt or deform, Teflon maintains its structural integrity and key properties, making it suitable for heat-sealing equipment, industrial presses, and other thermal processes.

Non-Stick and Dielectric Properties

The famous non-stick surface of Teflon prevents other materials—from adhesives to biological matter—from bonding to it.

This same chemical stability also makes it an excellent electrical insulator (a dielectric material), preventing the flow of electricity. This is critical for applications in electronics and electrical components.

How These Properties Translate to Practical Benefits

The theoretical properties of Teflon sheets deliver tangible advantages when applied in real-world engineering scenarios. Understanding this link is key to identifying its best use cases.

Reducing Wear and Extending Lifespan

By minimizing friction between moving parts, Teflon sheets dramatically reduce wear and tear. This is essential for components like bearings, gears, and slide plates.

Less friction means less abrasive wear and less heat buildup, which are primary causes of mechanical failure. The result is a significantly longer operational lifespan for critical machinery components.

Enhancing Machinery and Process Efficiency

In machinery, low-friction surfaces mean less energy is wasted overcoming resistance. This leads to more efficient operation and lower power consumption for equipment like conveyor systems.

In manufacturing, the non-stick surface simplifies processes by preventing material buildup. This allows for cleaner operations, faster cleanup, and higher quality output in applications like printing and molding.

Protecting Components in Harsh Environments

The chemical inertness of Teflon makes it the perfect material for lining pipes, tanks, and vessels that handle aggressive chemicals.

This protective barrier prevents corrosion of the underlying metal structure, ensuring the safety and longevity of expensive capital equipment in the chemical, pharmaceutical, and semiconductor industries.

Understanding the Trade-offs and Limitations

No material is perfect. A clear-eyed assessment of Teflon's limitations is just as important as understanding its strengths. Acknowledging these trade-offs is critical for successful implementation.

Low Mechanical Strength

Teflon is a relatively soft material. It has poor tensile strength and is susceptible to creep, which is slow deformation when placed under a persistent load.

It should not be used for structural components that must bear significant weight or force. Its strength is in its surface properties, not its structural capacity.

Susceptibility to Abrasion

While Teflon has extremely low friction, it is not highly resistant to abrasion from hard particles. Sharp or abrasive materials can gouge or wear away the surface.

In environments with abrasive contaminants, a different material or a filled grade of Teflon might be necessary to ensure durability.

High Thermal Expansion

Compared to metals, Teflon has a very high coefficient of thermal expansion. It expands and contracts significantly with changes in temperature.

Engineers must account for this in designs that require tight tolerances, leaving adequate room for this expansion to prevent parts from binding or warping.

Making the Right Choice for Your Application

Your decision to use Teflon should be based on a clear alignment between its core strengths and your primary engineering goal.

- If your primary focus is reducing friction and wear in moving parts: Teflon is an excellent choice for low-load bearings, slide plates, and wear strips where lubrication is difficult or undesirable.

- If your primary focus is handling corrosive chemicals or high-purity substances: Its chemical inertness makes it the definitive material for linings, seals, and gaskets in aggressive chemical environments.

- If your primary focus is a non-stick surface for high-temperature processes: Heat-resistant Teflon sheets are ideal for release liners, heat-sealing surfaces, and protecting equipment from adhesive buildup.

- If your primary focus is high mechanical strength and rigidity: You should select a different material, as Teflon is not suited for load-bearing structural applications.

By understanding both its remarkable strengths and its specific limitations, you can leverage Teflon to solve targeted engineering problems with precision and reliability.

Summary Table:

| Key Property | Key Benefit for Engineering |

|---|---|

| Low Friction | Reduces wear, lowers energy consumption, improves efficiency in moving parts. |

| Chemical Inertness | Protects components from corrosion, ideal for harsh chemical environments. |

| High Heat Resistance | Maintains performance up to 500°F (260°C), suitable for thermal processes. |

| Non-Stick Surface | Prevents material buildup, simplifies cleaning, and ensures process purity. |

Ready to solve your toughest engineering challenges with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE sheets, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get components that deliver superior chemical resistance, reduce friction, and extend equipment life—whether you need a prototype or a high-volume order.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What makes expanded PTFE gaskets resistant to corrosion? Unmatched Chemical Inertness for Harsh Environments

- What makes PTFE expansion bellows durable and long-lasting? Unmatched Chemical & Thermal Resistance

- What should be considered when choosing a manufacturer for PTFE-lined bearings? Ensure Long-Term Reliability and Performance

- How should temperature-related seal performance issues be troubleshooted? A Step-by-Step Guide to Thermal Failure

- What are the main application areas of PTFE O-ring seals? Critical Seals for Demanding Industries

- What are the advantages of Teflon in industrial applications? Boost Durability and Efficiency

- What industries benefit from PTFE's non-stick properties? Boost Efficiency and Purity

- How do PTFE bushes reduce friction between moving parts? Achieve Maintenance-Free, Low-Friction Motion