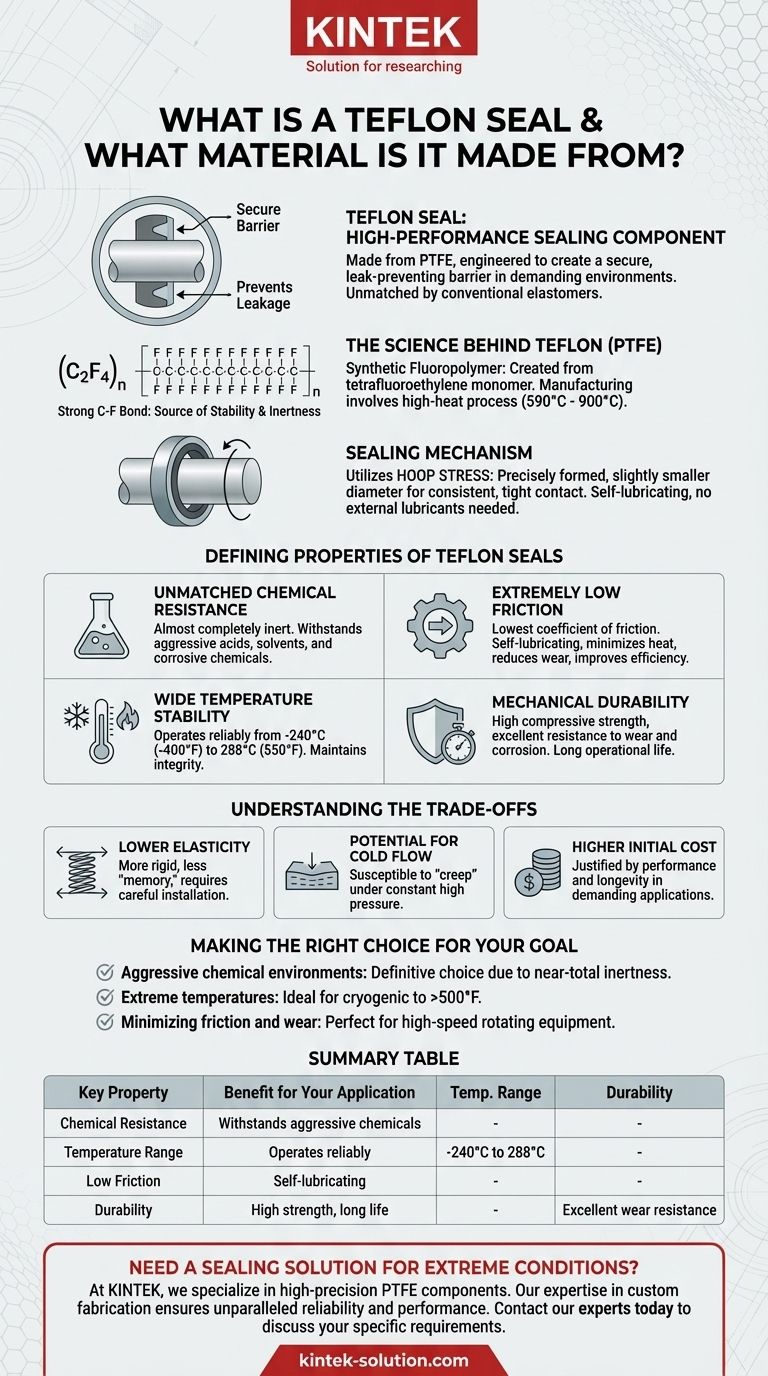

At its core, a Teflon seal is a high-performance sealing component made from Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer more commonly known by its DuPont brand name, Teflon. These seals are engineered to create a secure and efficient barrier between two surfaces, preventing leakage in demanding operational environments. Their function can range from lip seals in rotating shafts to bellows in mechanical seals.

While many materials can form a seal, Teflon (PTFE) is chosen when standard seals would fail. Its unique molecular structure provides a combination of chemical inertness, low friction, and extreme temperature tolerance that is unmatched by conventional elastomers.

The Science Behind Teflon (PTFE)

The Core Material: A Synthetic Fluoropolymer

A Teflon seal's remarkable properties originate from its material, Polytetrafluoroethylene (PTFE). It is a thermoplastic polymer created from the monomer tetrafluoroethylene.

The chemical formula for PTFE is (C2F4)n, indicating a long, repeating chain of carbon and fluorine atoms. This strong carbon-fluorine bond is the source of the material's famous stability and inertness.

The manufacturing process involves combining ingredients like fluorspar, chloroform, and hydrofluoric acid in a reaction chamber heated to very high temperatures, between 590°C and 900°C.

The Sealing Mechanism

While there are various designs, such as lip seals, the fundamental principle often involves mechanical pressure. The PTFE sealing element is precisely formed to be slightly smaller in diameter than the shaft it will seal.

This size difference utilizes hoop stress, creating a consistent, tight contact around the shaft's circumference. This ensures a reliable seal without the need for external lubricants, as the material itself is self-lubricating.

Defining Properties of Teflon Seals

Unmatched Chemical Resistance

Due to its stable chemical structure, PTFE is almost completely inert. It can withstand exposure to the most aggressive acids, solvents, and corrosive chemicals that would quickly degrade other sealing materials.

Extremely Low Friction

Teflon is renowned for having one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical in high-speed applications, as it minimizes heat generation, reduces wear, and improves operational efficiency.

Wide Temperature Stability

Teflon seals perform reliably across an exceptionally broad temperature range. They maintain their integrity and sealing capability in conditions from as low as -240°C (-400°F) up to 288°C (550°F).

Mechanical Durability

Beyond its core properties, Teflon offers high compressive strength and excellent resistance to wear and corrosion. This leads to a long, maintenance-free operational life, even under high speeds or impact loads.

Understanding the Trade-offs

Lower Elasticity

Compared to rubber-based seals (elastomers), PTFE is a more rigid material. It has less "memory" or elasticity, meaning it is less forgiving of surface imperfections on the sealing surfaces and may require more careful installation.

Potential for Cold Flow

Under a constant, high-pressure load, PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. In certain high-pressure static applications, this must be accounted for in the design to maintain a long-term seal.

Higher Initial Cost

As a high-performance engineered material, the initial cost of a Teflon seal is typically higher than that of standard seals made from materials like nitrile or neoprene. This cost is justified by its performance and longevity in applications where other materials would fail.

Making the Right Choice for Your Goal

Ultimately, the decision to use a Teflon seal is driven by the demands of the application.

- If your primary focus is aggressive chemical environments: A Teflon seal is the definitive choice due to its near-total chemical inertness.

- If your primary focus is extreme temperatures: Its stability from cryogenic levels to over 500°F makes it ideal for applications far beyond the range of rubber seals.

- If your primary focus is minimizing friction and wear: Its self-lubricating nature is perfect for high-speed rotating equipment or dry-running applications where maintenance is difficult.

Selecting a Teflon seal is a strategic decision for any application where performance and reliability in harsh conditions cannot be compromised.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Chemical Resistance | Withstands aggressive acids, solvents, and corrosive chemicals. |

| Temperature Range | Operates reliably from -240°C (-400°F) to 288°C (550°F). |

| Low Friction | Self-lubricating for high-speed, low-wear, and dry-running use. |

| Durability | High compressive strength and excellent wear resistance for long life. |

Need a sealing solution for extreme conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal that delivers unmatched reliability and performance.

Contact our experts today to discuss your specific requirements and get a solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance