In demanding applications, PTFE-lined valves consistently outperform traditional all-metal valves by providing a chemically inert barrier between the process media and the valve body. This design offers superior corrosion resistance, non-stick properties, and thermal stability, leading to a longer service life and reduced maintenance costs, especially when compared to stainless steel or rubber-lined alternatives.

The choice between a PTFE-lined valve and a traditional metallic valve is not about which is universally "better," but which is the right tool for a specific operational challenge. PTFE excels in corrosive environments where metals would fail, while metallic valves remain the standard for high-pressure, high-temperature, or general utility services.

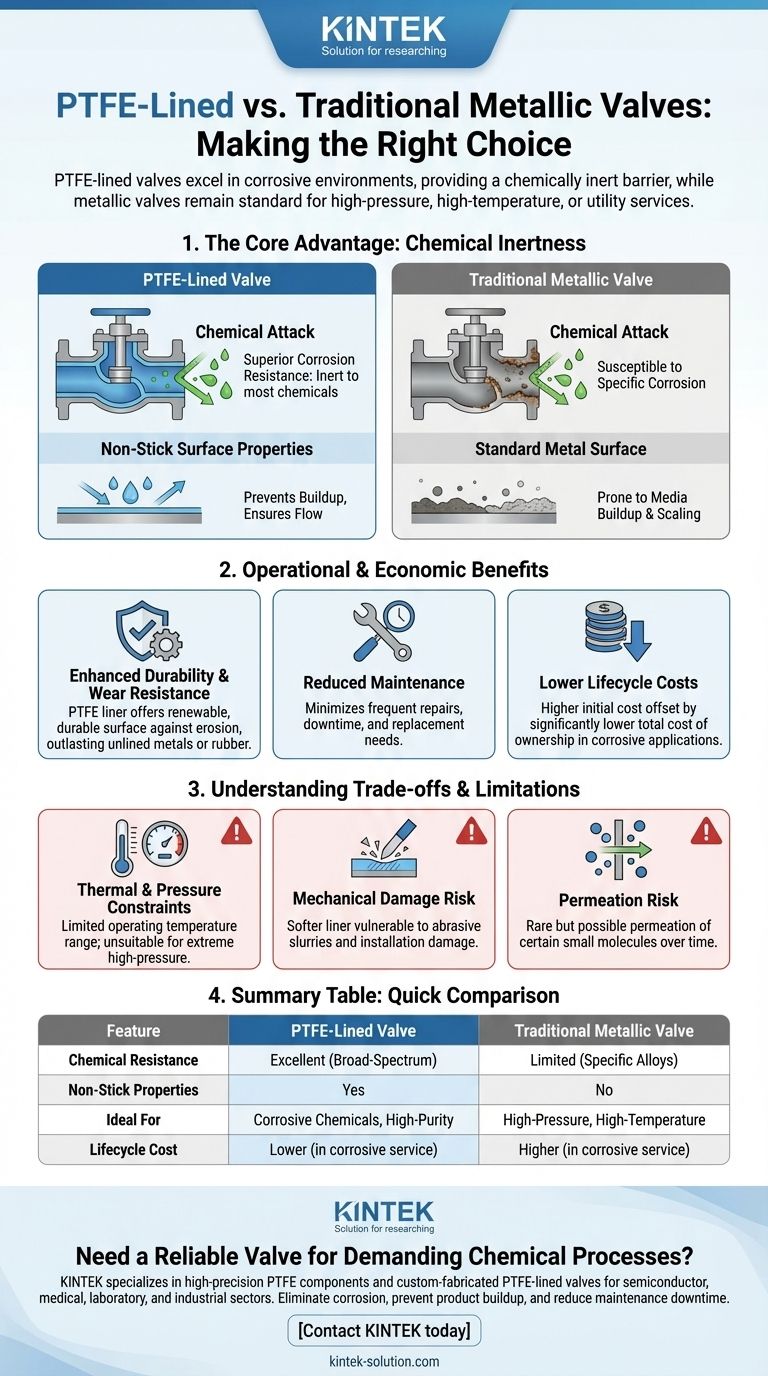

The Core Advantage: Chemical Inertness

The primary reason to select a PTFE-lined valve is its near-total immunity to chemical attack. This property stems from the unique molecular structure of Polytetrafluoroethylene (PTFE).

Superior Corrosion Resistance

The bond between carbon and fluorine atoms in PTFE is exceptionally strong and stable. This makes the material chemically inert, meaning it will not react with the vast majority of industrial chemicals, including strong acids, bases, and solvents.

Unlike specialized metal alloys that are resistant to only a specific range of chemicals, a PTFE liner offers broad-spectrum protection. This insulates the structural metal of the valve body from any corrosive media, preventing degradation and extending the valve's operational life indefinitely.

Non-Stick Surface Properties

PTFE has an extremely low coefficient of friction, creating a non-stick surface that is often compared to "wet ice on wet ice."

This property is critical in processes where media buildup, scaling, or contamination is a concern. The smooth, non-porous liner prevents material from adhering to the valve's internal surfaces, ensuring consistent flow and simplifying clean-out procedures.

Operational and Economic Benefits

Beyond its chemical resistance, the PTFE-lined design delivers tangible advantages in performance and total cost of ownership.

Enhanced Durability and Wear Resistance

While metal valves are susceptible to erosive and corrosive wear, the PTFE liner acts as a durable, renewable surface. It protects the valve's core components from the direct impact of the process fluid.

This results in significantly less degradation over time compared to unlined metallic valves or even rubber-lined alternatives, which can swell, tear, or degrade with chemical exposure.

Reduced Maintenance and Lifecycle Costs

The initial cost of a PTFE-lined valve may be higher than a standard metallic valve, but its total cost of ownership is often far lower in corrosive applications.

By preventing corrosion and minimizing wear, these valves dramatically reduce the need for frequent maintenance, repairs, and replacement. This translates to less downtime and lower long-term operational expenditures.

Understanding the Trade-offs and Limitations

While highly effective, PTFE-lined valves are not a universal solution. Understanding their limitations is key to proper application and avoiding premature failure.

Thermal and Pressure Constraints

PTFE has a defined operating temperature range. Exceeding its upper temperature limit can cause the liner to soften, deform, or fail. Similarly, it is not suitable for extremely high-pressure applications where a solid metal body is required for structural integrity.

Susceptibility to Mechanical Damage

The PTFE liner is softer than metal and can be damaged by highly abrasive slurries containing sharp particles. Care must also be taken during installation to avoid scratching or gouging the liner, which would create a path for corrosive media to attack the valve body.

Risk of Permeation

While rare, certain small-molecule gases and chemicals can slowly permeate through the PTFE liner over extended periods. In highly critical services, this can eventually lead to corrosion of the valve body from behind the liner.

Making the Right Choice for Your Application

Selecting the correct valve requires a clear understanding of your process conditions and primary goals.

- If your primary focus is handling aggressive or corrosive chemicals: A PTFE-lined valve is almost always the superior choice for reliability and long-term cost savings.

- If your primary focus is high-purity or preventing product buildup: The non-stick properties of PTFE make it the ideal selection for industries like pharmaceuticals or food processing.

- If your primary focus is high-pressure or high-temperature service (outside PTFE's limits): A traditional valve constructed from a suitable metallic alloy is the necessary and correct solution.

- If your primary focus is general utility (like water or air) without corrosion concerns: A standard metallic valve provides the most cost-effective and straightforward solution.

Ultimately, specifying the right valve is about matching the material's strengths to the demands of your application.

Summary Table:

| Feature | PTFE-Lined Valve | Traditional Metallic Valve |

|---|---|---|

| Chemical Resistance | Excellent (Broad-Spectrum) | Limited (Specific Alloys) |

| Non-Stick Properties | Yes | No |

| Ideal For | Corrosive Chemicals, High-Purity | High-Pressure, High-Temperature |

| Lifecycle Cost | Lower (in corrosive service) | Higher (in corrosive service) |

Need a Reliable Valve for Demanding Chemical Processes?

Choosing the right valve is critical for the safety, efficiency, and longevity of your operations. KINTEK specializes in manufacturing high-precision PTFE components, including custom-fabricated PTFE-lined valves, for the semiconductor, medical, laboratory, and industrial sectors.

Our valves provide the chemical inertness and non-stick surface you need to:

- Eliminate corrosion and extend service life.

- Prevent product buildup and ensure consistent flow.

- Reduce maintenance downtime and lower your total cost of ownership.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application requirements.

Contact KINTEK today to discuss your valve specifications and get a solution engineered for peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the significance of the low friction coefficient in PTFE processing machines? Enhance Quality and Machine Life

- What role does the PTFE sheet play in design transfer? Achieve Flawless, Professional Results

- How is PTFE's low friction property utilized in industrial applications? Boost Efficiency & Reduce Wear

- What are the main properties of EPDM valve seats in butterfly valves? A Guide to Superior Water & Steam Sealing

- How do PTFE envelope gaskets address the limitations of pure PTFE gaskets? Enhance Sealing Performance

- How do expanded PTFE (ePTFE) gaskets differ from other types? Solve Cold Flow & Seal Imperfect Flanges

- What are the three most common machining processes for Teflon? Master CNC Turning, Milling & Drilling

- What does the material compatibility chart indicate about PTFE? A Guide to Its Broad Chemical Resistance