At their core, PTFE rotary shaft seals enhance machine longevity by providing a superior barrier against the primary causes of mechanical failure: friction, heat, and chemical degradation. Unlike traditional elastomeric seals, their unique properties protect the rotating shaft from wear, operate reliably at extreme speeds and temperatures, and resist attack from aggressive fluids, ensuring the entire system runs longer and more efficiently.

The decision to use a PTFE seal is about more than just preventing leaks; it's a strategic choice to reduce wear on critical components, expand operational limits, and minimize downtime over the machine's entire lifecycle.

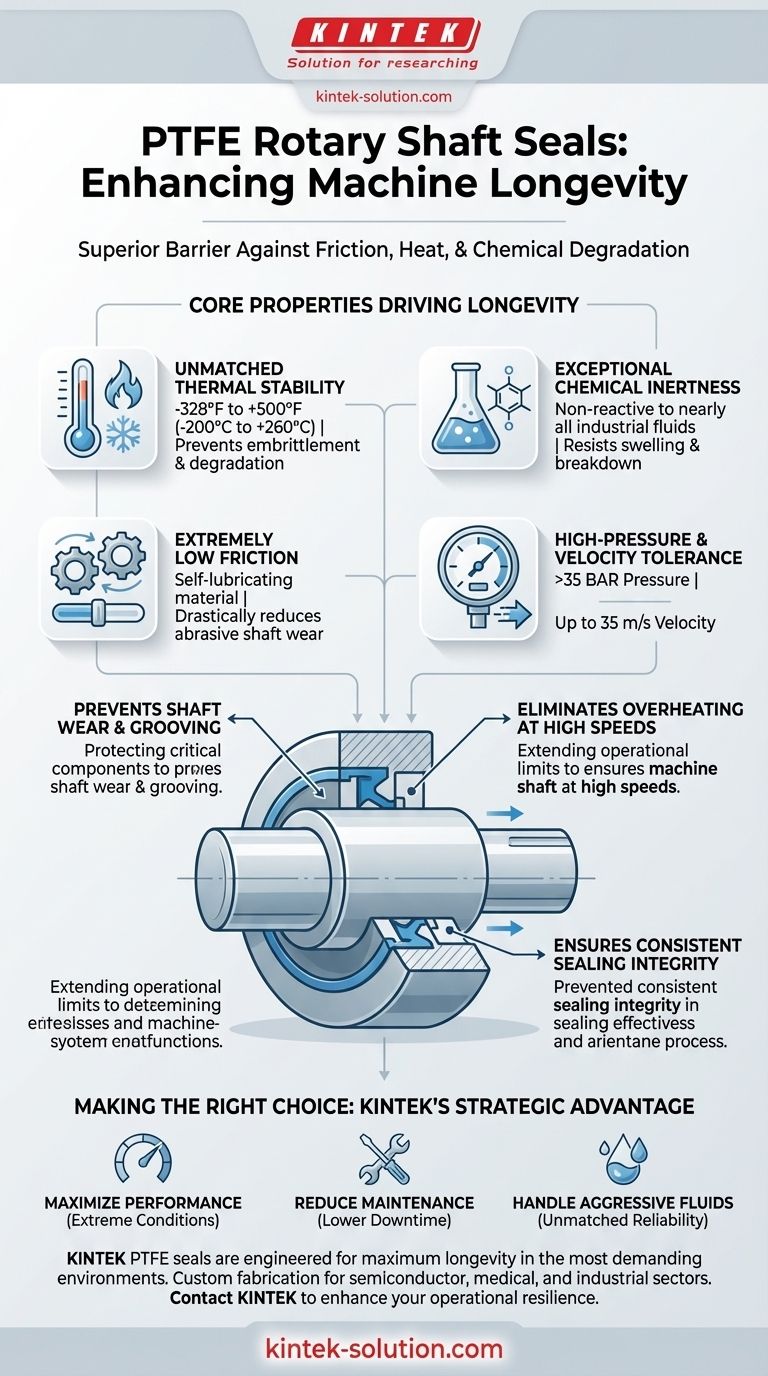

The Core Properties Driving Longevity

To understand how PTFE seals extend machine life, we must first look at the fundamental properties of the material itself. These characteristics solve the most common challenges that lead to seal failure and subsequent equipment damage.

### Unmatched Thermal Stability

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -328°F to +500°F (-200°C to +260°C).

This stability prevents the seal from becoming brittle in extreme cold or degrading in high heat, which are common failure points for other materials. This ensures a consistent, reliable seal under fluctuating thermal conditions.

### Exceptional Chemical Inertness

PTFE is non-reactive and inert to nearly all industrial chemicals, lubricants, and aggressive fluids.

This property prevents the seal from swelling, shrinking, or breaking down when exposed to harsh substances. The seal maintains its structural integrity, protecting internal components from both contamination and lubricant loss for longer.

### Extremely Low Friction

A key characteristic of PTFE is its remarkably low coefficient of friction, making it a self-lubricating material.

This non-stick property drastically reduces the friction between the seal lip and the rotating shaft. Less friction means less heat generation and, most importantly, significantly less abrasive wear on the shaft itself.

### High-Pressure and High-Velocity Tolerance

PTFE rotary shaft seals are engineered to perform where others fail, handling pressures exceeding 35 BAR and surface velocities up to 35 m/s.

This robustness allows machinery to be designed for higher performance without compromising the lifespan of the sealing components, directly contributing to the longevity of high-demand equipment.

How These Properties Translate to Machine Protection

The material properties of PTFE are not just theoretical advantages. They deliver tangible protection that directly extends the operational life of the machinery they are installed in.

### Preventing Shaft Wear and Grooving

The primary benefit of PTFE's low friction is the prevention of shaft grooving. Over time, traditional seals can wear a groove into the shaft, which compromises sealing and requires costly shaft repair or replacement.

By minimizing this abrasive action, PTFE seals preserve the integrity of the shaft, a critical and expensive machine component.

### Eliminating Overheating at High Speeds

In high-RPM applications, friction from a standard seal can generate significant heat. This heat can cause the seal to fail prematurely and can also damage nearby bearings and lubricants.

PTFE's low-friction nature allows it to run at high surface speeds without overheating, protecting the entire rotating assembly from thermal damage.

### Ensuring Consistent Sealing Integrity

Because PTFE does not degrade from chemical or thermal stress, it provides a more stable and predictable sealing barrier over its lifespan.

This consistency prevents intermittent leaks and the ingress of contaminants that can slowly degrade bearings, gears, and other internal components, thereby extending the life of the whole machine.

Understanding the Trade-offs and Maintenance

While highly effective, achieving the maximum lifespan from PTFE seals requires acknowledging their characteristics and committing to proper protocols.

### The Importance of Proper Installation

PTFE seals are generally more rigid than their elastomeric counterparts. This means they can be less forgiving of installation errors.

Proper tooling and careful handling are critical to avoid damaging the seal lip during installation, as even a small nick can compromise performance.

### The Role of Proactive Maintenance

Longevity is not automatic. Regular inspections are necessary to check for any potential leaks or visible damage to the seal.

Monitoring operating conditions like temperature and pressure helps ensure they remain within the seal's design limits. Damaged seals must be replaced promptly to prevent equipment failure and costly downtime.

Making the Right Choice for Your Application

Choosing the correct seal is a critical engineering decision. The unique advantages of PTFE make it the optimal choice for specific goals focused on extending machine life and performance.

- If your primary focus is maximizing performance in extreme conditions: PTFE is the superior choice for its ability to handle high speeds, pressures, and temperatures that would cause other seals to fail.

- If your primary focus is reducing maintenance and downtime: The extended lifespan of PTFE seals reduces the frequency of replacement, directly contributing to greater operational uptime and lower labor costs.

- If your primary focus is handling aggressive chemicals or fluids: PTFE's chemical inertness provides unmatched reliability, protecting both the seal and the internal machine components from degradation.

Ultimately, selecting a PTFE rotary shaft seal is an investment in the operational resilience and longevity of your critical machinery.

Summary Table:

| Key Property | Benefit for Machine Longevity |

|---|---|

| Extreme Thermal Stability (-328°F to +500°F) | Prevents seal failure from heat/cold, ensuring reliability. |

| Exceptional Chemical Inertness | Resists swelling/degradation from aggressive fluids, protecting internal components. |

| Extremely Low Friction | Reduces shaft wear and grooving, preserving a critical, expensive component. |

| High-Pressure & Velocity Tolerance (35+ BAR, 35 m/s) | Enables high-performance operation without compromising seal lifespan. |

Ready to extend the life of your critical machinery?

PTFE rotary shaft seals from KINTEK are engineered for maximum longevity in the most demanding environments. We manufacture precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution tailored to your specific operational needs, helping you reduce downtime and maintenance costs.

Contact KINTEK today to discuss how our PTFE seals can protect your equipment and enhance your operational resilience.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What environmental factors do PTFE bellows resist? Superior Chemical and Thermal Resilience for Demanding Applications

- What are common applications of machined Teflon/PTFE parts? Solve Extreme Engineering Challenges

- Why is filled-PTFE often chosen for rotary shaft seal lips? For Unmatched Performance in Extreme Conditions

- What makes PTFE envelope gaskets appropriate for food and pharmaceutical applications? Ensure Purity and Compliance

- How is the PTFE lining process carried out? A Guide to Flawless Corrosion Protection

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- How is PTFE utilized for low friction properties in load-bearing applications? Achieve Maintenance-Free, High-Efficiency Motion

- What are some common variations and grades of PTFE used in seals? Optimize Performance with the Right Material