To understand the common grades of PTFE for seals, you must look beyond the base material and into the world of specialized fillers. While pure (virgin) PTFE offers unparalleled chemical resistance, it is mechanically soft. Fillers are added to create a range of compounds, each engineered to enhance specific properties like wear resistance, strength, and resistance to deformation under load.

The core principle is simple: pure PTFE provides the chemical and thermal foundation, while fillers provide the mechanical strength required for demanding sealing applications. The choice of grade is always a trade-off between maximizing mechanical performance and maintaining chemical compatibility.

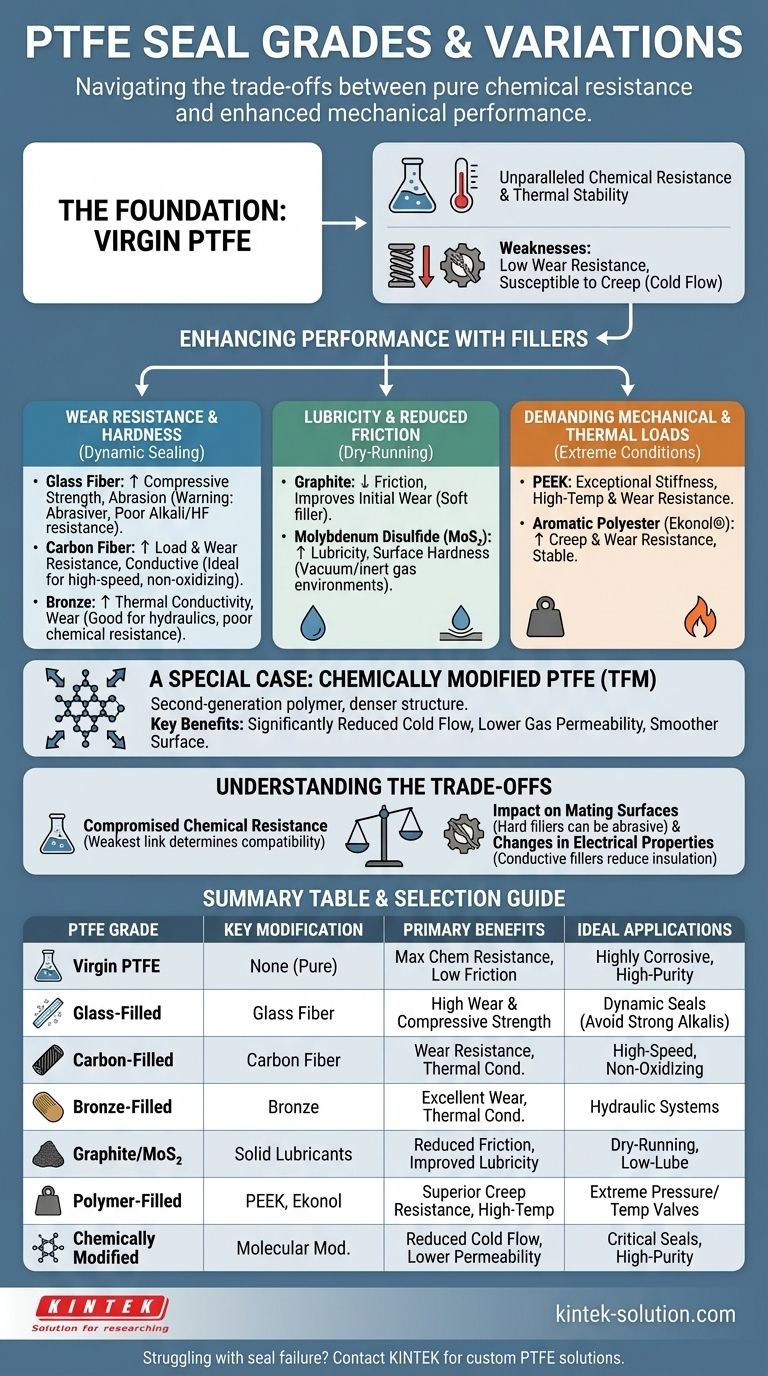

The Foundation: Virgin PTFE

What is Virgin PTFE?

Virgin PTFE is pure, unfilled Polytetrafluoroethylene. It contains no recycled material or added fillers.

This grade is the benchmark for chemical resistance and thermal stability. It is also an excellent electrical insulator and possesses the lowest coefficient of friction of any solid material.

Strengths and Limitations for Seals

For sealing, virgin PTFE's key strengths are its near-universal chemical inertness and wide operating temperature range.

However, its primary weaknesses are significant: it has low wear resistance and is highly susceptible to creep, also known as cold flow. This is the tendency of the material to slowly deform over time when under a constant load, which can lead to seal failure.

Enhancing Performance with Fillers

Fillers are blended with virgin PTFE to overcome its mechanical limitations. The choice of filler directly targets a specific performance weakness.

For Increased Wear Resistance and Hardness

These fillers create a harder, more durable material suitable for dynamic sealing applications.

- Glass Fiber: This is one of the most common fillers. It dramatically increases compressive strength and wear resistance. However, it can be abrasive to softer mating surfaces and has poor resistance to strong alkalis and hydrofluoric acid.

- Carbon Fiber: Carbon adds excellent compressive strength, load resistance, and wear resistance. It is also electrically conductive and less abrasive than glass, making it ideal for high-speed dynamic seals in non-oxidizing chemical environments.

- Bronze: This filler provides excellent wear resistance and high thermal conductivity, which helps dissipate heat in high-speed rotary applications. Its primary drawback is poor chemical resistance, limiting its use to hydraulic systems and non-corrosive environments.

For Improved Lubricity and Reduced Friction

These fillers act as solid lubricants, making them ideal for dry-running or poorly lubricated conditions.

- Graphite: A soft filler that reduces the coefficient of friction and improves initial wear properties. It is often combined with other fillers, like carbon, to create a robust, low-friction compound.

- Molybdenum Disulfide (MoS₂): Commonly known as "Moly," this additive significantly improves lubricity and surface hardness. It is particularly effective in vacuum and inert gas environments.

For Demanding Mechanical and Thermal Loads

These high-performance polymeric fillers are used in the most extreme sealing conditions.

- PEEK (Polyether Ether Ketone): Adding PEEK creates a compound with exceptional stiffness, high-temperature performance, and superior wear resistance, making it suitable for high-pressure and high-temperature valve seats and seals.

- Aromatic Polyester (Ekonol®): This polymer filler improves creep and wear resistance without significantly increasing the coefficient of friction, providing a stable material for precision seals.

A Special Case: Chemically Modified PTFE

What is Chemically Modified PTFE?

Often referred to as TFM, this is not a filled grade but a second-generation version of the PTFE polymer itself. A small amount of a modifying agent is co-polymerized, resulting in a denser molecular structure.

Key Advantages for Seals

Chemically Modified PTFE offers significantly reduced cold flow and lower permeability to gases. Its smoother, less porous surface makes it an excellent choice for high-purity applications and critical seals where deformation resistance is paramount.

Understanding the Trade-offs

Adding fillers is not a universal improvement; it is an engineering compromise designed to enhance specific properties, often at the expense of others.

Compromised Chemical Resistance

This is the most critical trade-off. Fillers like glass and bronze can be attacked by chemicals that pure PTFE would easily resist. The chemical compatibility of the filled grade is determined by its weakest component—the filler.

Impact on Mating Surfaces

Hard fillers, particularly glass, can be abrasive and cause wear on softer shaft or bore materials over time. Softer fillers like graphite are less of a concern.

Changes in Electrical Properties

Virgin PTFE is a superb electrical insulator. Adding conductive fillers like carbon or bronze will dramatically reduce its insulating properties, which can be a critical factor in some applications.

Selecting the Right PTFE Grade for Your Seal

Your choice must be driven by the specific demands of the application environment.

- If your primary focus is maximum chemical inertness and purity: Virgin or Chemically Modified PTFE is the only choice.

- If your primary focus is dynamic sealing with high wear resistance: Consider Carbon, Glass, or Bronze filled grades, carefully matching the filler to your chemical environment and mating surface hardness.

- If your primary focus is reducing friction in low-lubrication conditions: Grades filled with Graphite or Molybdenum Disulfide (MoS₂) are ideal.

- If your primary focus is resisting deformation under high loads (creep): Look to Chemically Modified PTFE or compounds with high-performance fillers like PEEK or Carbon.

By understanding how each grade modifies the fundamental properties of PTFE, you can select a material precisely engineered for your specific sealing challenge.

Summary Table:

| PTFE Grade | Key Fillers/Modifications | Primary Benefits | Ideal Applications |

|---|---|---|---|

| Virgin PTFE | None (Pure Polymer) | Maximum chemical resistance, low friction | Highly corrosive environments, high-purity systems |

| Glass-Filled | Glass Fiber | High wear resistance, compressive strength | Dynamic seals (avoid strong alkalis/HF) |

| Carbon-Filled | Carbon Fiber | Wear resistance, thermal conductivity, less abrasive | High-speed dynamic seals, non-oxidizing environments |

| Bronze-Filled | Bronze | Excellent wear resistance, thermal conductivity | Hydraulic systems, non-corrosive rotary seals |

| Graphite/MoS₂-Filled | Graphite, Molybdenum Disulfide | Reduced friction, improved lubricity | Dry-running or low-lubrication conditions |

| High-Performance Polymer Filled | PEEK, Aromatic Polyester | Superior creep resistance, high-temperature stability | High-pressure/temperature valve seats, extreme conditions |

| Chemically Modified (TFM) | Molecular Modification (No Fillers) | Reduced cold flow, lower gas permeability, smoother surface | Critical seals, high-purity applications |

Struggling with seal failure due to wear, cold flow, or chemical incompatibility? The right PTFE grade is critical for reliability and longevity. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your seals are engineered to withstand your specific operational demands. Let us help you select or custom-formulate the perfect PTFE grade for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE slide bearings superior to conventional expansion plates and rollers? Achieve Maintenance-Free Structural Movement

- What issue can arise due to PTFE's softness during machining? Mastering Dimensional Accuracy

- How do spring-energized PTFE seals perform in high-pressure environments? Unlock Superior Sealing Reliability

- What is the primary function of PTFE pneumatic valves? Control Corrosive Media with Unmatched Reliability

- What are the primary applications of PTFE V-rings? Seal Moving Parts in Demanding Systems

- What is PTFE packing and what are its primary characteristics? Master Sealing for Extreme Conditions

- In which industries are PTFE rotary shaft lip seals commonly used? Essential for Extreme Conditions

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings