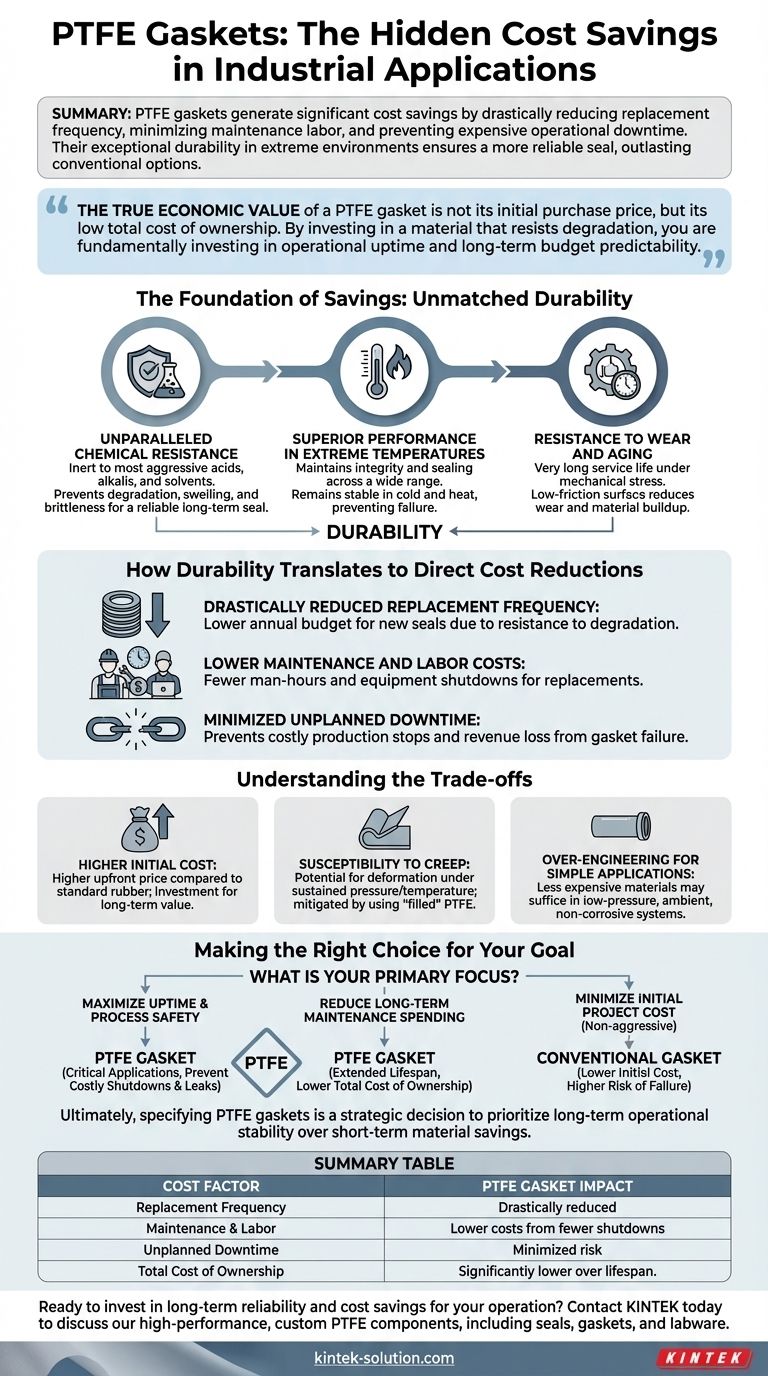

In short, PTFE gaskets generate significant cost savings by drastically reducing the frequency of replacement, minimizing maintenance labor, and preventing expensive operational downtime. Their exceptional durability in extreme chemical and thermal environments means they outlast conventional gaskets, providing a more reliable seal that avoids costly failures, product loss, and safety incidents.

The true economic value of a PTFE gasket is not its initial purchase price, but its low total cost of ownership. By investing in a material that resists degradation, you are fundamentally investing in operational uptime and long-term budget predictability.

The Foundation of Savings: Unmatched Durability

The cost-saving benefits of Polytetrafluoroethylene (PTFE) are a direct result of its unique material properties. It is engineered to survive in conditions where other materials quickly fail.

Unparalleled Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, alkalis, and solvents.

This chemical stability prevents the gasket from degrading, swelling, or becoming brittle. This ensures a reliable, long-term seal and prevents leaks of valuable or hazardous materials.

Superior Performance in Extreme Temperatures

PTFE gaskets maintain their integrity and sealing capability across a wide temperature range.

Unlike many elastomers that can turn brittle in the cold or soften at high heat, PTFE remains stable, preventing failures that lead to emergency shutdowns and repairs.

Resistance to Wear and Aging

PTFE has a very long service life, even under continuous mechanical stress and pressure.

Its low-friction, non-stick surface reduces wear and also helps prevent material buildup, which can contribute to process efficiency and self-cleaning in some applications.

How Durability Translates to Direct Cost Reductions

A gasket's durability has a cascading effect on an operation's budget. A more resilient gasket does more than just last longer; it reduces costs across several key areas.

Drastically Reduced Replacement Frequency

Because PTFE gaskets do not degrade easily, they need to be replaced far less often than their counterparts. This directly lowers the annual budget allocated for purchasing new seals.

Lower Maintenance and Labor Costs

Fewer replacements mean fewer man-hours spent on maintenance. This frees up technicians for other critical tasks and reduces the labor costs associated with shutting down equipment, removing failed components, and installing new gaskets.

Minimized Unplanned Downtime

This is often the largest and most critical cost saving. A single gasket failure can shut down an entire production line, leading to immense losses in productivity and revenue.

The reliability of PTFE minimizes the risk of these unplanned and costly interruptions, ensuring operational continuity.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Acknowledging its limitations is key to making a sound technical and financial decision.

The Higher Initial Cost

PTFE gaskets typically have a higher upfront purchase price compared to standard rubber or composite gaskets. This initial expense can be a barrier if a project's budget is strictly focused on initial capital outlay rather than long-term operational cost.

Susceptibility to Creep

Under sustained pressure and temperature, standard PTFE can be prone to "creep" or "cold flow," where the material slowly deforms. This can lead to a loss of bolt torque and sealing pressure over time.

This is often mitigated by using "filled" PTFE gaskets, which include materials like glass or graphite to improve mechanical stability, but it requires careful selection for the specific application.

Over-Engineering for Simple Applications

In low-pressure, ambient-temperature systems handling non-corrosive media, the advanced properties of PTFE may be unnecessary. In such cases, a less expensive material can be a perfectly suitable and more cost-effective choice.

Making the Right Choice for Your Goal

Selecting the optimal gasket material requires aligning its properties with your primary operational and financial objectives.

- If your primary focus is maximizing uptime and process safety: PTFE is the superior choice for critical applications, as its reliability directly prevents costly shutdowns and hazardous leaks.

- If your primary focus is reducing long-term maintenance spending: The extended lifespan of PTFE gaskets delivers a lower total cost of ownership by minimizing expenditures on both replacement parts and labor.

- If your primary focus is minimizing initial project cost for a non-aggressive application: A conventional, lower-cost gasket may be sufficient, but this choice accepts a higher risk of future failure and associated downtime.

Ultimately, specifying PTFE gaskets is a strategic decision to prioritize long-term operational stability over short-term material savings.

Summary Table:

| Cost Factor | PTFE Gasket Impact |

|---|---|

| Replacement Frequency | Drastically reduced due to exceptional chemical and thermal resistance. |

| Maintenance & Labor | Lower costs from fewer shutdowns and part replacements. |

| Unplanned Downtime | Minimized risk of costly production stops from gasket failure. |

| Total Cost of Ownership | Significantly lower over the gasket's lifespan. |

Ready to invest in long-term reliability and cost savings for your operation?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets deliver maximum durability and efficiency, from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can reduce your total cost of ownership and enhance your operational uptime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What installation methods are available for PTFE slide bearings? Choose the Right Method for Your Structure

- What is the significance of the short valve stroke in PTFE lined check valves? Achieve Rapid Backflow Prevention

- What finishing operations might be required after machining Teflon parts? Deburring, Polishing & More

- What is the melting point of PTFE and its usable temperature range? Master the Thermal Limits for Your Application

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments

- What materials are used in PTFE piston seals? A Guide to the Two-Part System for Superior Performance

- How does interference level vary between PTFE seal designs? Choose the Right Fit for Your Application

- What role do spring-energized PTFE seals play in the automotive industry? Ensure Reliability in Extreme Conditions