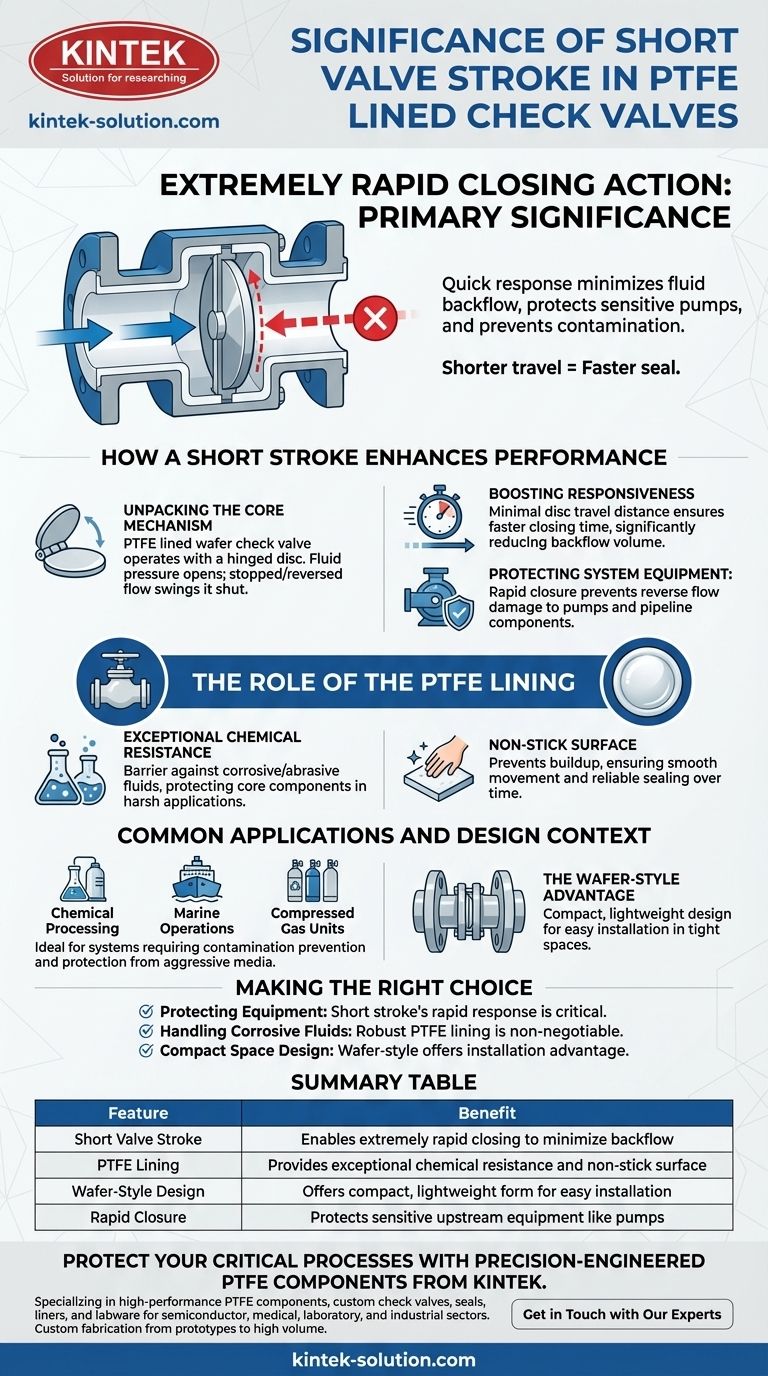

The primary significance of a short valve stroke in a PTFE lined check valve is its ability to deliver an extremely rapid closing action. This quick response is critical for minimizing fluid backflow, which in turn protects sensitive upstream equipment like pumps and prevents contamination in process systems. The shorter the distance the internal disc has to travel, the faster it can seal against reverse flow.

In environments handling aggressive chemicals or requiring precise fluid control, system integrity is paramount. A short valve stroke is not merely an incremental improvement; it is a core design feature that ensures immediate and reliable backflow prevention, safeguarding both equipment and process purity.

How a Short Stroke Enhances Valve Performance

The mechanical design of a check valve directly impacts its effectiveness. The length of the stroke—the distance the internal disc travels between its fully open and fully closed positions—is a defining characteristic.

Unpacking the Core Mechanism

A PTFE lined wafer check valve operates using an internal disc on a hinge. When fluid moves in the intended direction, its pressure pushes the disc open, allowing flow. If the flow stops or attempts to reverse, the disc swings shut to seal the opening.

Boosting Responsiveness

A short stroke means the disc has a very small distance to travel to create a seal. This minimal travel distance translates directly into a faster closing time, significantly reducing the volume of fluid that can flow backward before the valve shuts completely.

Protecting System Equipment

This rapid closure is crucial for protecting pumps and other pipeline components. Unchecked reverse flow can cause pumps to spin backward, leading to significant mechanical damage. The short stroke acts as a critical safety feature against this damaging event.

The Role of the PTFE Lining

The valve's material composition is just as important as its mechanical design. The PTFE (Polytetrafluoroethylene) lining provides distinct advantages that complement the short stroke.

Exceptional Chemical Resistance

The primary function of the PTFE lining is to provide a barrier against corrosive or abrasive fluids. This protects the valve's core components from chemical attack, ensuring long-term durability and reliable operation in harsh industrial applications like chemical dosing systems.

Non-Stick Surface

PTFE is renowned for its non-stick properties. This prevents materials from building up on the valve's internal disc and seat, which could otherwise hinder movement and prevent a proper seal. This ensures the short stroke mechanism remains effective over the valve's lifespan.

Common Applications and Design Context

The combination of a fast-acting short stroke and a durable PTFE lining makes these valves ideal for specific, demanding scenarios.

Where These Valves Excel

You will commonly find PTFE lined check valves in chemical processing, marine operations, and compressed gas units. In these systems, preventing cross-contamination and protecting equipment from aggressive media is non-negotiable.

The Wafer-Style Advantage

Many of these valves utilize a wafer-style design. This means the valve body is compact and designed to be sandwiched between two pipe flanges, making it lightweight and easy to install in tight spaces without requiring extensive pipe modifications.

Making the Right Choice for Your Goal

Selecting the correct valve requires understanding how its features align with your system's primary needs.

- If your primary focus is protecting sensitive equipment from backflow: The rapid response enabled by the short stroke is the most critical feature for safeguarding your pumps and pipelines.

- If your primary focus is handling corrosive or aggressive fluids: The robust PTFE lining is the non-negotiable element, ensuring the valve's long-term survival and operational integrity.

- If your primary focus is system design in a compact space: The wafer-style construction offers a significant installation advantage, simplifying integration into complex piping arrangements.

Ultimately, understanding how these design elements work in concert empowers you to specify a valve that delivers both immediate protection and lasting reliability.

Summary Table:

| Feature | Benefit |

|---|---|

| Short Valve Stroke | Enables extremely rapid closing action to minimize backflow. |

| PTFE Lining | Provides exceptional chemical resistance and a non-stick surface. |

| Wafer-Style Design | Offers a compact, lightweight form for easy installation in tight spaces. |

| Rapid Closure | Protects sensitive upstream equipment like pumps from damage. |

Protect your critical processes with precision-engineered PTFE components from KINTEK.

Does your application in the semiconductor, medical, laboratory, or industrial sector demand reliable backflow prevention and chemical resistance? KINTEK specializes in manufacturing high-performance PTFE components, including custom check valves, seals, liners, and labware.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact us today to discuss how our solutions can enhance your system's integrity and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments