After machining Teflon parts, finishing operations are nearly always required to correct for the material's unique properties. These processes typically include deburring, fine-grit sanding, and polishing to achieve the necessary surface quality and precise dimensional accuracy that raw machining often cannot produce on its own.

Because of Teflon's inherent softness and tendency to deform under pressure, post-machining finishing is not merely cosmetic. It is a critical manufacturing step to remove burrs, correct dimensional inaccuracies, and achieve the specific surface characteristics required for high-performance applications.

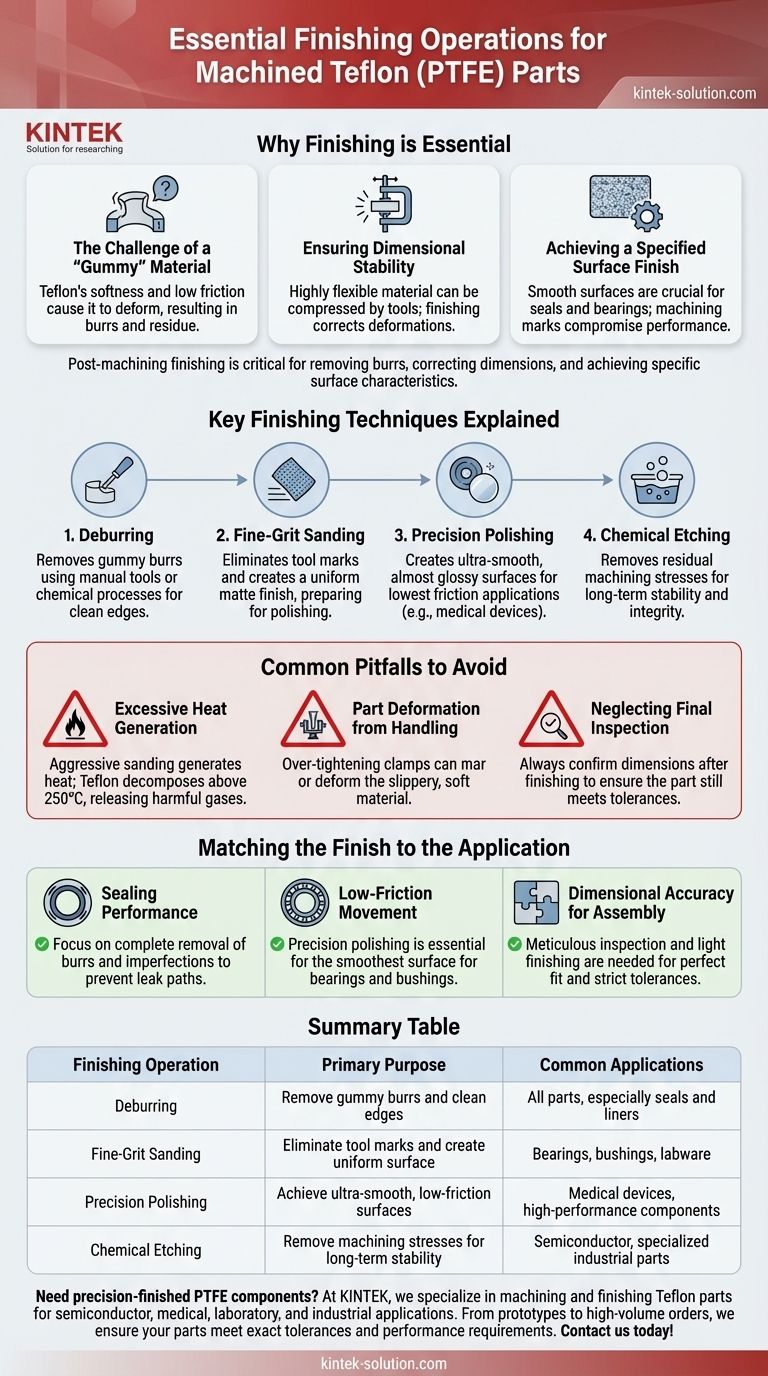

Why Finishing is Essential for Teflon Parts

Understanding why Teflon (PTFE) requires careful finishing starts with its core properties. Unlike rigid metals that produce clean chips, Teflon behaves very differently during cutting.

The Challenge of a "Gummy" Material

Teflon's softness and low coefficient of friction cause it to deform rather than shear cleanly. This often results in burrs and a "gummy" residue along machined edges, which must be removed.

Ensuring Dimensional Stability

The material is highly flexible and can be easily compressed or distorted by tool pressure or clamping forces. Finishing operations help correct for any minor deformations that occurred, ensuring the final part meets its specified tolerances.

Achieving a Specified Surface Finish

Many Teflon applications, such as seals and bearings, depend on an exceptionally smooth surface. Raw machining marks can compromise performance, making polishing and sanding necessary to achieve the desired low-friction characteristic.

Key Finishing Techniques Explained

The right technique depends on the part's geometry and its final application. Each process addresses a specific type of imperfection left over from machining.

Deburring

This is the most common first step. Burrs are carefully removed using manual tools or, in some cases, specialized chemical processes to ensure clean edges without damaging the part's surface.

Fine-Grit Sanding

To remove more significant tool marks and create a uniform matte finish, fine-grit sandpaper is often used. This step prepares the surface for final polishing if a smoother finish is required.

Precision Polishing

For applications demanding the lowest possible friction, such as in medical devices or high-performance bearings, polishing is used. This creates a smooth, almost glossy surface that enhances the part's performance.

Chemical Etching

In highly sensitive applications, chemical etching can be employed. This specialized process helps remove residual stresses imparted into the material during machining, improving the part's long-term stability and integrity.

Common Pitfalls to Avoid

Finishing Teflon is a delicate process where it's easy to damage the part if proper care is not taken. Awareness of these challenges is key to success.

Excessive Heat Generation

Aggressive sanding or polishing can generate heat. Since Teflon begins to decompose above 250°C and can release harmful gases, it is critical to control friction and use cooling methods to maintain safe temperatures.

Part Deformation from Handling

Teflon's slippery and soft surface makes it difficult to hold securely for finishing operations. Over-tightening a vise or clamp can easily mar or deform the part, undoing the precision of the machining process.

Neglecting Final Inspection

The final and most critical step is a thorough inspection. Use precision measuring tools to confirm that the finishing processes have not inadvertently altered the part's dimensions beyond its specified tolerances.

Matching the Finish to the Application

The required level of finishing depends entirely on the part's final function. Not every component needs to be polished to a mirror shine.

- If your primary focus is sealing performance: Your priority is the complete removal of all burrs and surface imperfections that could create a potential leak path.

- If your primary focus is low-friction movement: Precision polishing is essential to create the smoothest possible surface for bearings, bushings, or sliding components.

- If your primary focus is dimensional accuracy for assembly: Meticulous inspection and light, careful finishing are needed to ensure the part meets strict tolerances for a perfect fit.

Ultimately, a methodical approach to finishing transforms a roughly machined Teflon component into a reliable, high-performance part.

Summary Table:

| Finishing Operation | Primary Purpose | Common Applications |

|---|---|---|

| Deburring | Remove gummy burrs and clean edges | All parts, especially seals and liners |

| Fine-Grit Sanding | Eliminate tool marks and create uniform surface | Bearings, bushings, labware |

| Precision Polishing | Achieve ultra-smooth, low-friction surfaces | Medical devices, high-performance components |

| Chemical Etching | Remove machining stresses for long-term stability | Semiconductor, specialized industrial parts |

Need precision-finished PTFE components? At KINTEK, we specialize in machining and finishing Teflon parts for semiconductor, medical, laboratory, and industrial applications. Our expertise in deburring, polishing, and custom fabrication ensures your parts meet exact tolerances and performance requirements—from prototypes to high-volume orders. Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers