The level of interference in a PTFE seal is a direct function of its mechanical design. This critical dimension is determined primarily by whether the seal is spring-energized or relies solely on the elasticity of the PTFE element. Non-spring-loaded designs require heavy interference to generate the necessary sealing force, while spring-energized seals use the spring to provide force, allowing for a much lighter interference fit.

The core difference lies in how sealing force is generated. A non-spring-loaded seal uses high material interference for its force, while a spring-energized seal uses a mechanical spring, allowing interference to be significantly reduced. This choice dictates the seal's performance in friction, wear, and its ability to handle shaft imperfections.

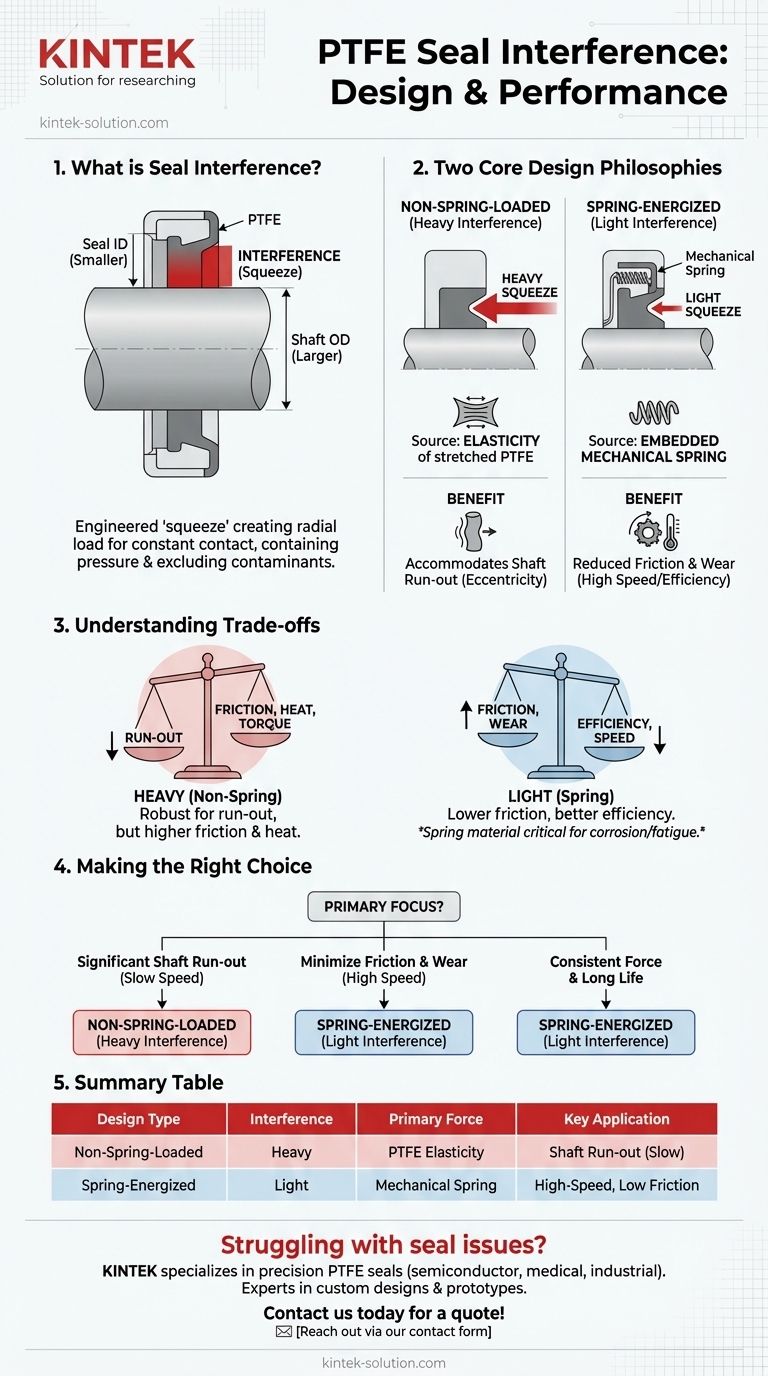

The Role of Interference in Sealing

Interference is the fundamental principle that makes a lip seal function. It's the engineered "squeeze" that ensures the seal remains in constant contact with the shaft.

What is Seal Interference?

Interference is the dimensional difference where the seal's inner diameter is intentionally made smaller than the shaft's outer diameter.

When installed, the seal lip is stretched over the shaft, creating a pre-loaded condition. This radial load is the force that enables the seal to contain pressure and exclude contaminants.

The Goal: Maintaining Constant Contact

The primary objective of this pre-load is to ensure the seal lip never loses contact with the dynamic shaft surface.

This is critical for accommodating variations like shaft run-out (eccentricity), thermal expansion or contraction, and pressure fluctuations.

The Two Core Design Philosophies

The method used to generate and maintain this radial load splits PTFE seals into two distinct categories, each with a different approach to interference.

Non-Spring-Loaded Seals: High Interference by Necessity

These simpler designs rely entirely on the stored energy in the stretched PTFE element to provide the sealing force.

To achieve an effective and consistent force, a heavy interference is required. This significant stretch ensures the seal has enough residual elasticity to follow the shaft's movement.

The Benefit: Following Shaft Run-out

The greater radial load generated by high interference makes these seals particularly effective at accommodating shaft run-out. The high pre-load helps the lip stay firmly planted on an eccentric shaft surface.

Spring-Energized Seals: Lighter Interference by Design

In a spring-energized seal, the primary sealing force comes from a metallic spring (like a cantilever, helical, or V-spring) embedded within the PTFE jacket.

Because the spring provides a constant and targeted force, the initial mechanical squeeze from the material itself can be greatly reduced. These designs operate with a light interference.

The Benefit: Reduced Friction and Wear

The lighter contact force from lower interference directly translates to lower friction and less heat generation. This often results in longer seal life and improved efficiency, especially in high-speed applications.

Understanding the Trade-offs

Neither design is universally superior; the correct choice is dictated by the specific demands of the application. Understanding their inherent limitations is key to proper selection.

The Downside of Heavy Interference

While robust for run-out, the high radial load of non-spring-loaded seals creates more friction. This leads to higher running temperatures, potentially accelerated wear, and requires more torque to turn the shaft. Installation can also require more force.

The Downside of Lighter Interference

A spring-energized seal's performance is dependent on the spring. In environments with highly corrosive media or extreme temperatures, the spring material must be carefully specified to avoid fatigue or failure, which would compromise the seal's function.

Making the Right Choice for Your Application

Selecting the appropriate interference level means matching the seal's design philosophy to your most critical performance requirement.

- If your primary focus is accommodating significant shaft run-out in a slow-moving application: A non-spring-loaded design with heavy interference is often the more robust choice.

- If your primary focus is minimizing friction and wear in a high-speed system: A spring-energized design with lighter interference is the superior solution.

- If your primary focus is consistent sealing force across a wide temperature range or long service life: A spring-energized design is generally preferred, as the metal spring provides a more stable force than the elasticity of a polymer.

By understanding this fundamental design difference, you can select a seal based on its mechanical performance rather than material alone.

Summary Table:

| Design Type | Interference Level | Primary Sealing Force Source | Key Application Consideration |

|---|---|---|---|

| Non-Spring-Loaded | Heavy Interference | Elasticity of stretched PTFE | Best for accommodating shaft run-out in slow-moving systems |

| Spring-Energized | Light Interference | Embedded mechanical spring | Ideal for high-speed applications requiring low friction and wear |

Struggling with seal friction, wear, or run-out issues? KINTEK specializes in precision PTFE seal solutions for semiconductor, medical, laboratory, and industrial applications. Our experts will help you select or custom-design the perfect seal—from prototypes to high-volume orders—ensuring optimal interference for your specific requirements.

Contact us today to discuss your project and get a quote: Reach out via our contact form

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance