In the automotive industry, spring-energized PTFE seals are mission-critical components used in high-performance systems where failure is not an option. They are found in engines, transmissions, fuel systems, and brakes, ensuring reliability and efficiency by providing a durable seal under extreme temperatures, high pressures, and contact with aggressive chemicals.

The core function of a spring-energized PTFE seal is to solve sealing challenges where traditional rubber or elastomeric seals would degrade and fail. It achieves this by combining the chemical and thermal resilience of a PTFE jacket with the constant mechanical force of an internal metal spring.

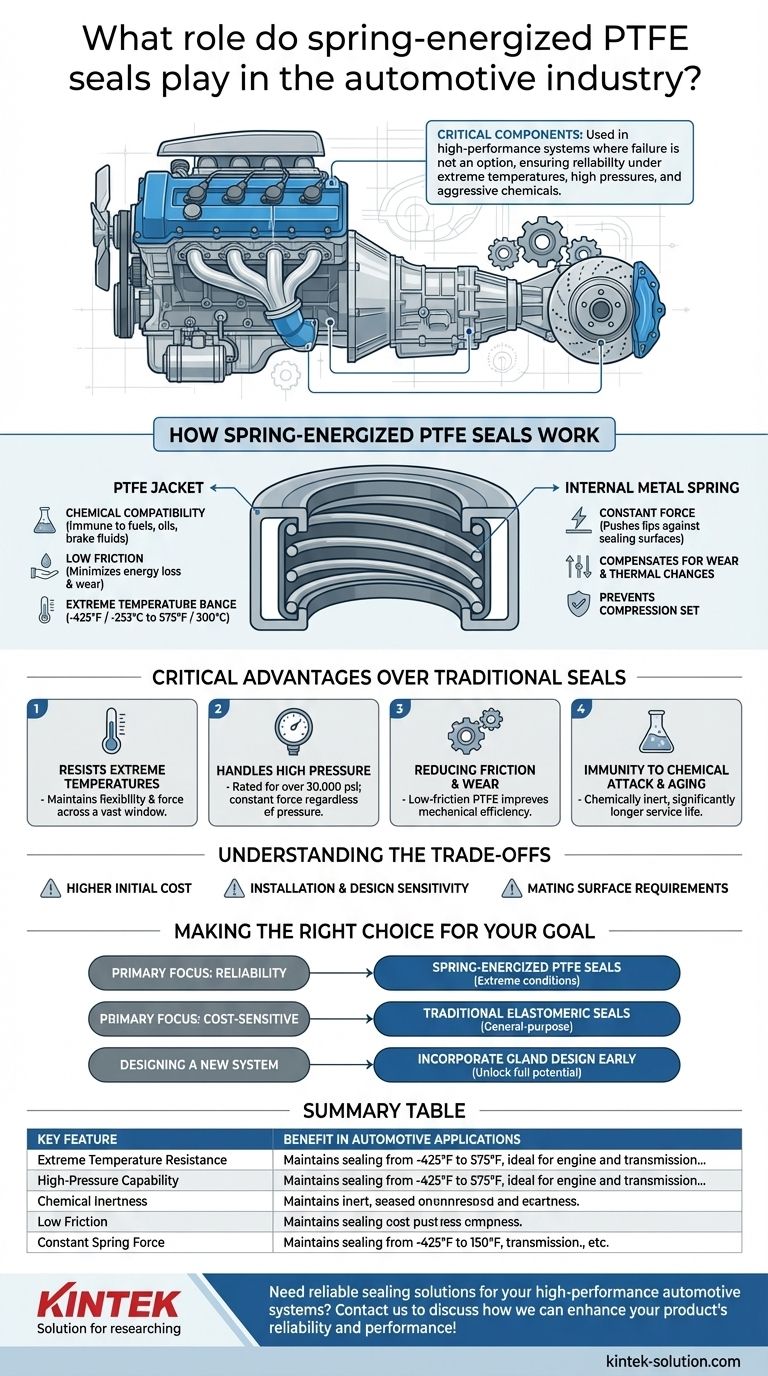

How Spring-Energized PTFE Seals Work

To understand their value, you must first understand their two-part design. The performance of the seal is a direct result of how its two core components work together.

The Role of the PTFE Jacket

The outer "jacket" is made from Polytetrafluoroethylene (PTFE), a fluoropolymer known for its remarkable properties.

This material provides universal chemical compatibility, making it immune to degradation from corrosive fuels, oils, and brake fluids. It also has an extremely low coefficient of friction, which minimizes energy loss and wear in rotating or reciprocating parts.

Finally, PTFE can withstand an exceptionally wide temperature range, from cryogenic lows (-425°F / -253°C) to high engine heat (575°F / 300°C), without becoming brittle or losing its integrity.

The Function of the Internal Spring

The metal spring, typically made of a corrosion-resistant alloy, sits inside the U-shaped channel of the PTFE jacket. This spring provides a constant, live-acting force that pushes the lips of the seal against the sealing surfaces.

This mechanical force is critical. It ensures a tight seal even at low pressures and, more importantly, compensates for seal wear, minor gland misalignments, and dimensional changes caused by thermal expansion and contraction. It gives the seal its permanent elasticity, preventing the "compression set" that plagues traditional elastomeric seals over time.

The Critical Advantages Over Traditional Seals

The reason these seals are specified for demanding automotive applications is that they overcome the inherent limitations of standard rubber O-rings or lip seals.

Resisting Extreme Temperatures

Conventional rubber seals can become brittle at low temperatures or degrade rapidly in the high heat of an engine or transmission. Spring-energized PTFE seals maintain their flexibility and sealing force across a vast operational temperature window.

Handling High Pressure

While a standard O-ring relies on system pressure to be fully energized, the internal spring provides a constant sealing force regardless of pressure. This makes them highly effective in both low-pressure and high-pressure environments, rated for over 30,000 psi.

Reducing Friction and Wear

The low-friction nature of PTFE reduces drag on moving components like crankshafts and transmission shafts. This improves mechanical efficiency and reduces heat generation, extending the life of both the seal and the component it is sealing.

Immunity to Chemical Attack and Aging

Automotive fluids can be aggressive. PTFE is nearly chemically inert, preventing the swelling, softening, or degradation that can destroy other seal materials. Unlike elastomers, it does not suffer from age-related embrittlement or compression set, giving it a significantly longer service life.

Understanding the Trade-offs

While highly effective, spring-energized PTFE seals are not a universal solution. Acknowledging their specific requirements is key to successful implementation.

Higher Initial Cost

These are advanced, multi-component seals engineered for high performance. Their manufacturing process and materials result in a higher piece price compared to simple elastomeric O-rings.

Installation and Design Sensitivity

The performance of a spring-energized seal is highly dependent on the hardware it's installed in. Correct gland design, tight tolerances, and a smooth, hard mating surface finish are critical to prevent leaks and premature wear.

Mating Surface Requirements

The reinforced PTFE material, while low-friction, can be more abrasive than a soft rubber seal. To ensure a long service life, the mating hardware (the shaft or bore) must typically be hardened to prevent scoring.

Making the Right Choice for Your Goal

The decision to use a spring-energized PTFE seal should be driven by the performance demands of the application.

- If your primary focus is reliability in extreme conditions: Spring-energized PTFE seals are the definitive choice for critical engine, transmission, fuel, and braking systems where high heat, pressure, or chemical exposure is present.

- If your primary focus is cost-sensitive, general-purpose sealing: Traditional elastomeric seals remain a suitable and cost-effective solution for static or low-duty dynamic applications with moderate temperatures and pressures.

- If you are designing a new high-performance system: Incorporate the specific gland design and surface finish requirements for a spring-energized seal early in the process to unlock its full performance potential.

Ultimately, choosing the right seal requires matching the material's capabilities to the mechanical, thermal, and chemical demands of the environment.

Summary Table:

| Key Feature | Benefit in Automotive Applications |

|---|---|

| Extreme Temperature Resistance | Maintains sealing from -425°F to 575°F, ideal for engine and transmission environments. |

| High-Pressure Capability | Rated for over 30,000 psi, ensuring reliability in fuel and braking systems. |

| Chemical Inertness | Resists degradation from aggressive automotive fluids like oils and fuels. |

| Low Friction | Reduces drag on moving parts, improving efficiency and extending component life. |

| Constant Spring Force | Compensates for wear and thermal changes, preventing leaks over time. |

Need reliable sealing solutions for your high-performance automotive systems? At KINTEK, we specialize in manufacturing precision PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get seals that meet the exact demands of your application. Contact us today to discuss how we can enhance your product's reliability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability