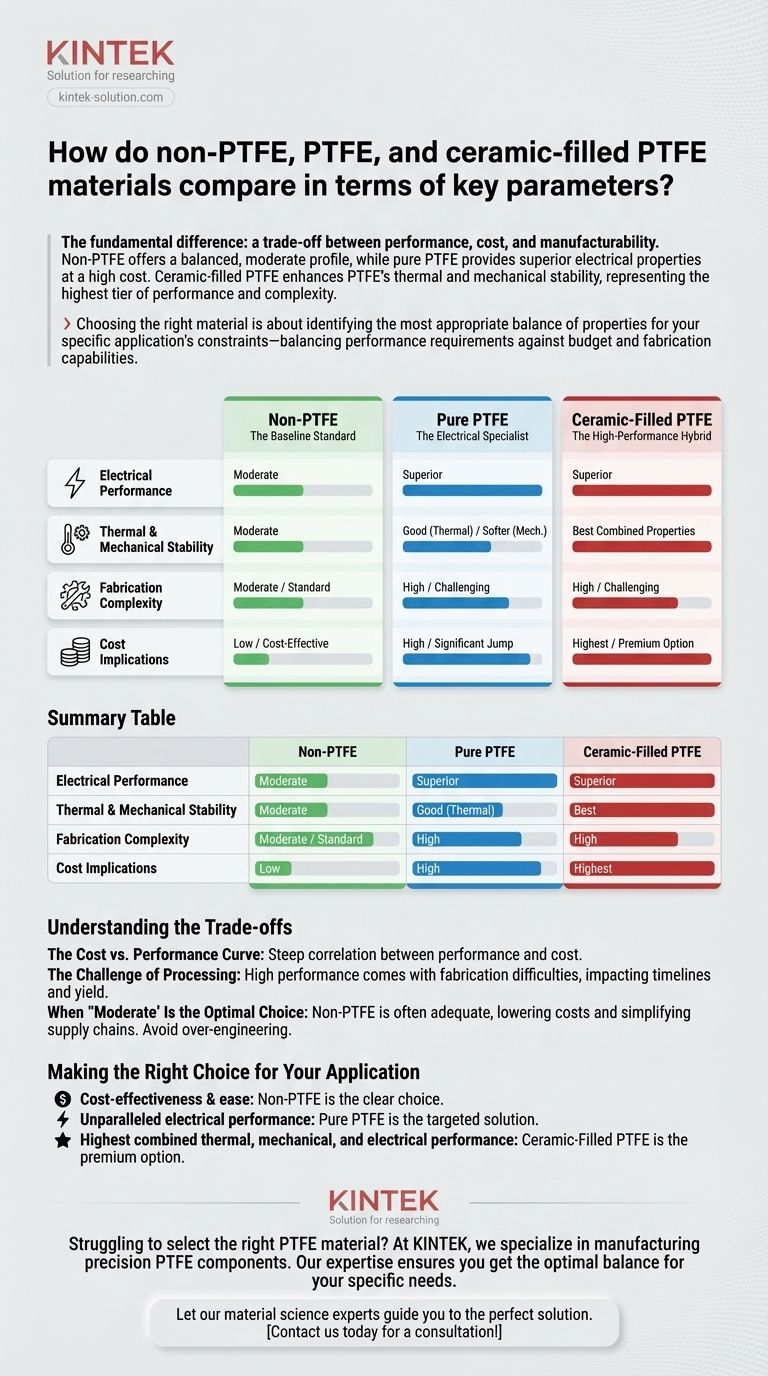

The fundamental difference between these material classes lies in a trade-off between performance, cost, and manufacturability. Non-PTFE materials offer a balanced, moderate profile, while pure PTFE provides superior electrical properties at a high cost. Ceramic-filled PTFE enhances PTFE's thermal and mechanical stability, representing the highest tier of performance and complexity.

Choosing the right material is not about finding the "best" option, but about identifying the most appropriate balance of properties for your specific application's constraints—balancing performance requirements against budget and fabrication capabilities.

Deconstructing the Core Materials

To make an informed decision, it's crucial to understand the distinct role each material type plays. They exist on a clear spectrum of cost and performance.

Non-PTFE: The Baseline Standard

Non-PTFE materials represent the most common and accessible option. They are engineered for a wide range of general-purpose applications.

Their performance across thermal and electrical parameters is considered moderate, making them a reliable workhorse where extreme conditions are not a factor.

Pure PTFE: The Electrical Specialist

Polytetrafluoroethylene (PTFE), commonly known by brand names like Teflon, is a high-performance fluoropolymer. Its defining characteristic is its superior electrical performance.

It also exhibits excellent chemical resistance to acids, alkalis, and solvents, along with remarkable thermal stability from -100°F to 450°F. Its low coefficient of friction makes it extremely durable and non-stick.

Ceramic-Filled PTFE: The High-Performance Hybrid

This material takes the excellent electrical properties of pure PTFE and enhances them by embedding ceramic particles into the polymer matrix.

The addition of ceramic significantly improves mechanical and thermal properties, making the material more rigid and stable at high temperatures. This creates a composite engineered for the most demanding applications.

A Head-to-Head Comparison

Evaluating these materials across key parameters reveals a clear hierarchy of performance and associated costs.

Electrical Performance

Non-PTFE materials offer moderate electrical insulation and signal integrity. They are suitable for countless standard applications.

Both PTFE and Ceramic-Filled PTFE provide superior electrical performance, making them essential for high-frequency or high-voltage electronics where signal loss must be minimized.

Thermal & Mechanical Stability

Ceramic-Filled PTFE stands out with the best combined thermal and mechanical properties. The ceramic filler adds rigidity and durability.

Pure PTFE offers excellent thermal stability over a wide temperature range but is mechanically softer. Non-PTFE materials provide a moderate level of performance in both areas.

Fabrication Complexity

Non-PTFE materials are generally the easiest to process, involving moderate fabrication complexity and standard manufacturing techniques.

Both PTFE and its ceramic-filled variant are challenging and complex to fabricate. Their high-temperature resistance and unique properties require specialized equipment and expertise.

Cost Implications

Cost is often the deciding factor. Non-PTFE materials are the most cost-effective choice for both raw material and processing.

Pure PTFE is significantly more expensive. Ceramic-Filled PTFE is the most premium option, reflecting its complex composition and superior all-around performance.

Understanding the Trade-offs

Selecting a material requires acknowledging the inherent compromises between its capabilities and its practical implementation.

The Cost vs. Performance Curve

There is a direct and steep correlation between performance and cost. Moving from Non-PTFE to PTFE-based materials introduces a significant jump in expenses. This is not just for the raw material but also for the specialized manufacturing required.

The Challenge of Processing

The high performance of PTFE comes at a price. Its resistance to heat and chemicals makes it difficult to mold, machine, and bond. This complexity can impact production timelines and yield, adding hidden costs beyond the material itself.

When 'Moderate' Is the Optimal Choice

For a vast number of applications, the "superior" properties of PTFE are unnecessary. Opting for a Non-PTFE material can provide more than adequate performance while dramatically lowering project costs and simplifying the supply chain. Over-engineering with a high-spec material is a common and costly pitfall.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical priority of your project.

- If your primary focus is cost-effectiveness and ease of manufacturing: Non-PTFE materials are the clear and logical choice.

- If your primary focus is unparalleled electrical performance for a specialized application: Pure PTFE is the targeted solution, provided you can absorb its higher cost and fabrication demands.

- If your primary focus is achieving the highest combined thermal, mechanical, and electrical performance: Ceramic-Filled PTFE is the premium option for mission-critical applications where budget is secondary.

Ultimately, aligning your material choice with your project's specific goals is the key to successful engineering.

Summary Table:

| Parameter | Non-PTFE | Pure PTFE | Ceramic-Filled PTFE |

|---|---|---|---|

| Electrical Performance | Moderate | Superior | Superior |

| Thermal/Mechanical Stability | Moderate | Good (Thermal) | Best |

| Fabrication Complexity | Moderate | High | High |

| Cost | Low | High | Highest |

Struggling to select the right PTFE material for your high-performance application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the optimal balance of performance, cost, and manufacturability for your specific needs, from prototypes to high-volume orders.

Let our material science experts guide you to the perfect solution. Contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties