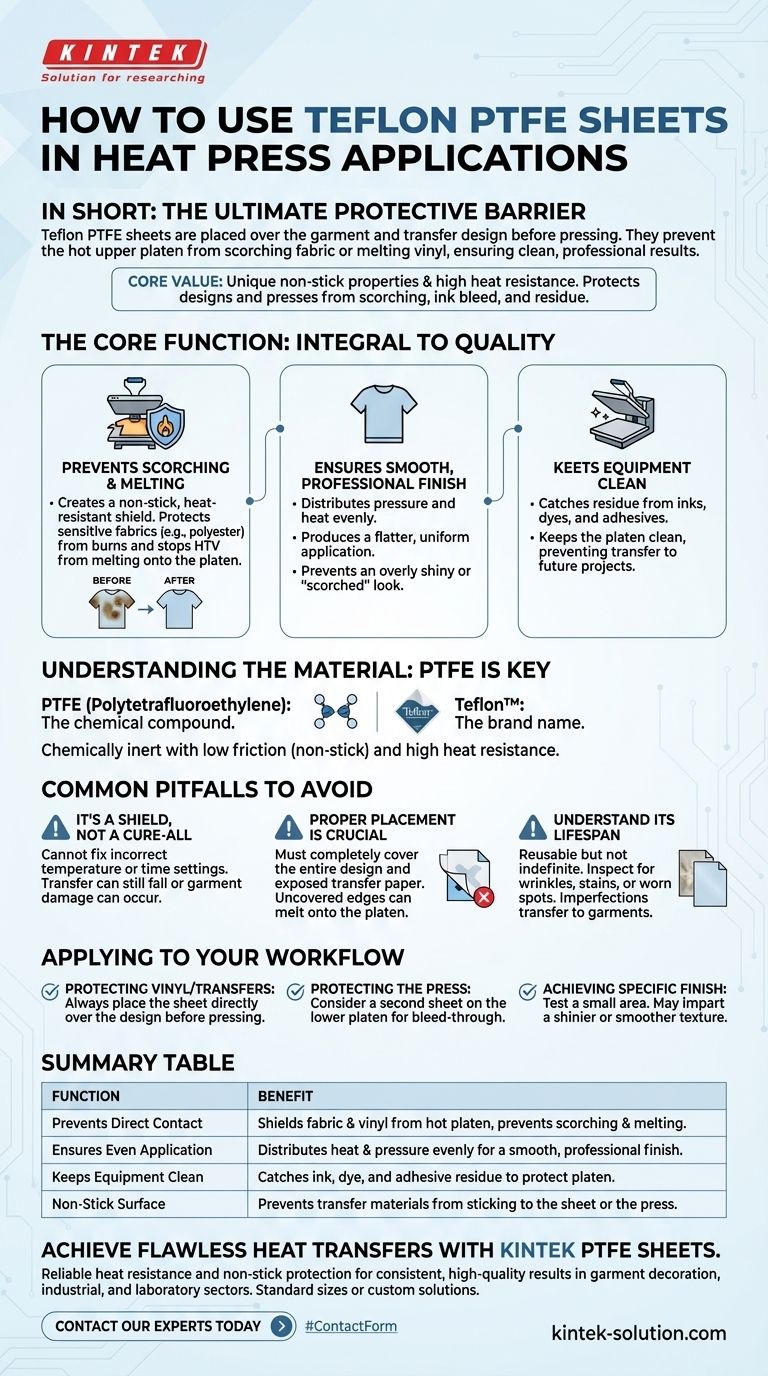

In short, Teflon PTFE sheets act as a protective barrier in heat press applications. They are placed over the garment and transfer design before pressing to prevent the hot upper platen from scorching the fabric or melting the vinyl. This ensures a clean, professional transfer without damaging the material or the equipment.

The core value of a PTFE sheet is its unique combination of non-stick properties and high heat resistance. This allows it to protect both your design and your heat press from scorching, ink bleed, and adhesive residue, making it an essential tool for consistent, high-quality results.

The Core Function of a PTFE Sheet in Heat Pressing

A PTFE sheet serves several critical functions during the heat transfer process. Its role goes beyond simple protection; it is integral to the quality of the final product.

Preventing Direct Contact and Scorching

The primary purpose of the sheet is to create a non-stick, heat-resistant shield between the heating element (the upper platen) and your project.

This barrier prevents the intense, direct heat from burning or discoloring the fabric, which is a common risk with sensitive materials like polyester. It also stops heat transfer vinyl (HTV) or other transfer media from melting and sticking to the platen itself.

Ensuring a Smooth, Professional Finish

The smooth surface of the PTFE sheet helps distribute pressure and heat more evenly across the design. This can help produce a flatter, more uniform application. By preventing direct contact, it helps avoid a "scorched" or overly shiny look on the transfer material.

Keeping Your Equipment Clean

Residue from inks, dyes, or adhesives can easily transfer to the hot platen of your press during a transfer.

A PTFE sheet catches this excess material, keeping the platen clean. A clean platen is crucial for future projects, as any residue can easily transfer to the next garment, ruining it.

Understanding the Material: PTFE is the Key

To understand why these sheets work so well, it's important to understand the material itself. You will see the terms "Teflon" and "PTFE" used interchangeably.

The Chemical and the Brand

PTFE is the abbreviation for Polytetrafluoroethylene, which is the actual chemical compound.

Teflon™ is simply the most well-known brand name for PTFE, created by the Chemours Company. For heat press applications, the terms effectively mean the same thing.

Why Its Properties are Ideal for Heat

PTFE is a fluoropolymer with exceptional properties. It is chemically inert and has one of the lowest coefficients of friction against any solid, which is why it's famously used for non-stick cookware.

This exact non-stick quality is what prevents transfers from adhering to the sheet or the platen. Combined with its ability to withstand high temperatures without degrading, it becomes the perfect material for heat press work.

Common Pitfalls to Avoid

While a PTFE sheet is a simple tool, using it incorrectly can lead to suboptimal results. Understanding its limitations is as important as knowing its benefits.

It's a Shield, Not a Cure-All

A PTFE sheet protects against scorching, but it cannot fix incorrect settings. If your temperature is too high or your press time is too long for a specific material, the transfer can still fail or the garment can be damaged underneath the sheet.

Proper Placement is Crucial

The sheet must completely cover the entire design and any exposed transfer paper or carrier sheet. If an edge of the design is left uncovered, it can easily melt onto the platen, creating an uneven finish and a mess to clean up.

Understand Its Lifespan

PTFE sheets are durable and reusable, but not indefinitely. Over time, they can develop wrinkles, stains, or worn spots. Any imperfection on the sheet's surface can potentially be impressed onto your garment, so inspect it regularly and replace it when it's no longer perfectly smooth.

Applying This to Your Heat Press Workflow

Using a PTFE sheet correctly is a simple step that significantly elevates the quality and consistency of your work.

- If your primary focus is protecting vinyl or transfers: Always place the sheet directly over your design before closing the press. This is the most common and critical use case.

- If your primary focus is protecting your heat press: Consider placing a second sheet on the lower platen to protect the foam pad from any ink bleed-through or adhesive residue from the back of the garment.

- If your primary focus is achieving a specific finish: Test a small area first. The sheet can sometimes impart a slightly shinier or smoother texture to the final transfer, which may or may not be your desired outcome.

Mastering the use of this simple protective sheet is a key step toward achieving flawless, professional-grade results with every press.

Summary Table:

| Function | Benefit |

|---|---|

| Prevents Direct Contact | Shields fabric and vinyl from the hot platen to prevent scorching and melting. |

| Ensures Even Application | Distributes heat and pressure evenly for a smooth, professional finish. |

| Keeps Equipment Clean | Catches ink, dye, and adhesive residue to protect your heat press platen. |

| Non-Stick Surface | Prevents transfer materials from sticking to the sheet or the press. |

Achieve flawless heat transfers with high-performance PTFE sheets from KINTEK.

Our precision-manufactured PTFE sheets provide the reliable heat resistance and non-stick protection you need for consistent, high-quality results in the garment decoration, industrial, and laboratory sectors. Whether you need standard sizes or custom-fabricated solutions for prototypes or high-volume orders, KINTEK delivers the precision and durability your application demands.

Contact our experts today to find the perfect PTFE solution for your heat press needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What is the conclusion regarding gasket selection for ISO tank applications? PTFE Envelope Gaskets for Safe Transport

- What makes PTFE seats suitable for demanding environments in butterfly valves? Unlock Chemical & Thermal Resilience

- What is the conclusion regarding PTFE bellows as a material choice? Prioritize Chemical Inertness and Flexibility

- What are the main advantages of PTFE O-Rings compared to elastomeric compounds? Superior Sealing in Extreme Conditions

- How is PTFE utilized in food processing lines? Enhance Safety, Efficiency & Equipment Lifespan

- Why is tool selection important in the CNC machining of PTFE parts? Achieve Precision and Quality

- Does modified PTFE (mPTFE) always outperform regular PTFE in seal performance? Make the Right Material Choice