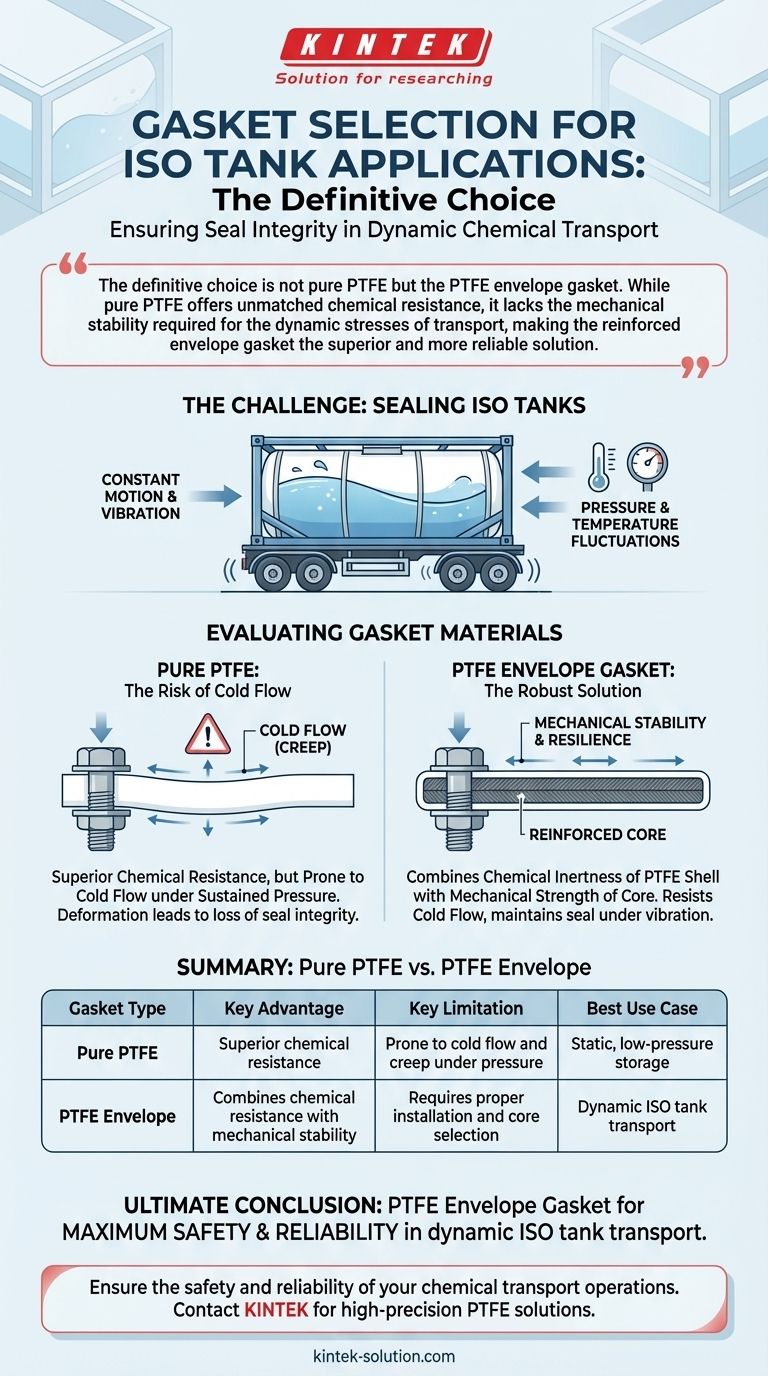

For ISO tank applications, the definitive choice is not pure PTFE but the PTFE envelope gasket. While pure PTFE offers unmatched chemical resistance, it lacks the mechanical stability required for the dynamic stresses of transport, making the reinforced envelope gasket the superior and more reliable solution.

The core issue is balancing chemical inertness with mechanical resilience. Pure PTFE excels at the former but fails at the latter under pressure, a phenomenon known as cold flow. PTFE envelope gaskets solve this by combining a chemically resistant PTFE shell with a strong, reinforced core, providing a seal that is both inert and robust.

The Unique Challenge of Sealing ISO Tanks

An ISO tank is not a static chemical drum. It is a dynamic environment where the integrity of the seal is constantly challenged.

Constant Motion and Vibration

During road, rail, or sea transport, the contents slosh, and the entire tank is subject to constant vibration. This puts continuous mechanical stress on all components, including the gaskets.

Pressure and Temperature Fluctuations

Tanks experience changes in internal pressure and temperature due to ambient conditions and the nature of the cargo. A reliable gasket must maintain a consistent seal across these varying conditions without failing.

Evaluating the Gasket Materials

The choice of gasket material must account for both the chemical being transported and the physical forces at play. This is where the distinction between pure and envelope PTFE becomes critical.

The Strengths of Pure PTFE

Polytetrafluoroethylene (PTFE) is renowned for its properties. It is nearly universally resistant to chemicals, can handle high temperatures, and has an extremely low-friction surface.

For applications involving aggressive chemicals, PTFE is the ideal material for the contact surface.

The Critical Weakness: Cold Flow

The primary drawback of pure PTFE is its tendency to "creep" or cold flow. Under the sustained compressive load of a bolted flange, the material slowly deforms and flows outward over time.

This deformation causes a loss of bolt torque and reduces the sealing pressure on the gasket face. In a dynamic environment like an ISO tank, this can quickly lead to a loss of seal integrity and dangerous leaks.

The Solution: The PTFE Envelope Gasket

A PTFE envelope gasket is a composite design. It features a thin "envelope" or jacket of pure PTFE that encases a more mechanically stable core material.

This design provides the best of both worlds. The PTFE envelope offers the universal chemical resistance needed for the wetted surface, while the inner core provides the mechanical strength and resilience to resist cold flow and maintain a tight seal under pressure and vibration.

Understanding the Trade-offs

While the envelope gasket is the technically superior solution for ISO tanks, a complete understanding requires acknowledging the practical considerations.

Importance of the Core Material

The performance of an envelope gasket is also dependent on its core. Common core materials include compressed non-asbestos fiber or various elastomers, each with different pressure, temperature, and recovery characteristics. Selecting the right core for the application is essential.

Proper Installation is Non-Negotiable

All PTFE-based gaskets are sensitive to installation. Over-tightening can fracture the PTFE envelope, while uneven torque can create leak paths. Proper bolt torque procedures are crucial for achieving a reliable seal, regardless of the gasket type.

Cost vs. Risk

A pure PTFE gasket is simpler in construction and generally less expensive than an envelope gasket. However, this initial cost saving comes at the expense of reliability and safety, creating a significant risk of failure, product loss, and environmental hazard during transport.

Making the Right Choice for Your Application

Selecting the correct gasket is not just a technical choice; it is a critical safety decision.

- If your primary focus is maximum safety and reliability for transporting chemicals: The PTFE envelope gasket is the only appropriate choice due to its resistance to mechanical failure under dynamic loads.

- If your primary focus is static storage with non-critical chemicals: While a pure PTFE gasket might function in a low-pressure, static setting, the inherent risk of cold flow still makes the envelope gasket a far more robust and reliable long-term solution.

Ultimately, engineering the seal to withstand the application's true demands is the foundation of safe chemical transport.

Summary Table:

| Gasket Type | Key Advantage | Key Limitation | Best Use Case |

|---|---|---|---|

| Pure PTFE | Superior chemical resistance | Prone to cold flow and creep under pressure | Static, low-pressure storage |

| PTFE Envelope | Combines chemical resistance with mechanical stability | Requires proper installation and core selection | Dynamic ISO tank transport |

Ensure the safety and reliability of your chemical transport operations.

For semiconductor, medical, laboratory, and industrial clients, selecting the right gasket is a critical safety decision. KINTEK specializes in manufacturing high-precision PTFE components, including custom envelope gaskets designed to withstand the dynamic stresses of ISO tank applications. We combine the chemical inertness of PTFE with the mechanical strength needed to resist cold flow.

Our team can help you specify the right core material and ensure your sealing solution is engineered for maximum safety and performance, from prototype to high-volume production.

Contact KINTEK today for a consultation on your specific sealing requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability