At its core, the manufacturing of molded PTFE bushes is a powder metallurgy process adapted for polymers. It involves compressing virgin or blended PTFE powder into a preform shape and then heating, or "sintering," it at a high temperature to fuse the particles into a solid, durable component.

The critical takeaway is that PTFE is not melt-processed like common plastics. Instead, it is shaped through high-pressure compression at room temperature and then baked in an oven, a process that dictates its final properties and design possibilities.

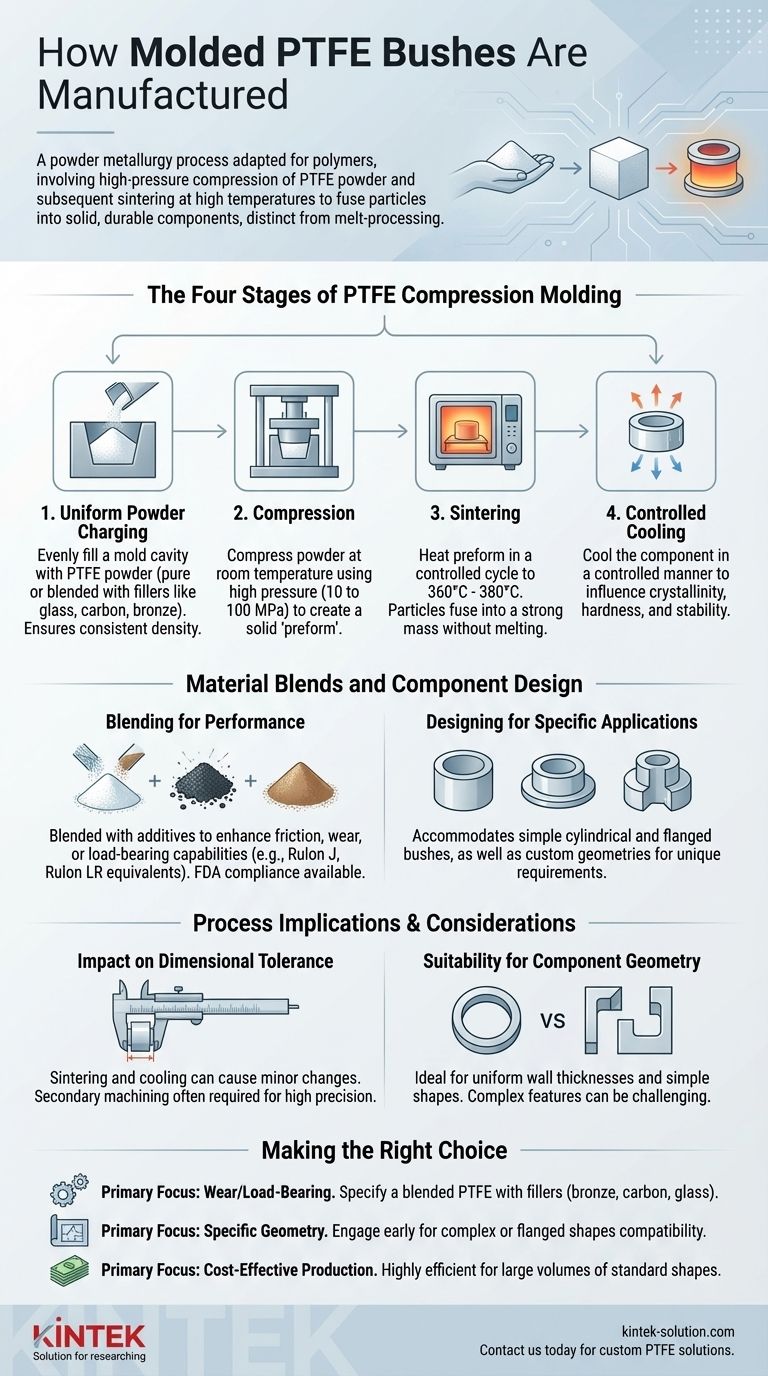

The Four Stages of PTFE Compression Molding

The creation of a molded PTFE bush is a precise, multi-stage process. Each step is critical for ensuring the final component meets the required mechanical and dimensional specifications.

Stage 1: Uniform Powder Charging

The first step is to evenly fill a mold cavity with PTFE powder. This powder may be pure PTFE or a blend containing fillers like glass, carbon, or bronze to enhance specific properties.

Ensuring the powder is distributed uniformly is essential for consistent density and preventing weak spots in the finished part.

Stage 2: Compression

Next, the powder is compressed within the mold at room temperature. This is done using high pressure, typically ranging from 10 to 100 MPa.

This compression phase transforms the loose powder into a fragile, solid block known as a "preform" that has the basic shape of the final bushing.

Stage 3: Sintering

The preform is carefully removed from the mold and placed into a sintering oven. It is heated in a precisely controlled cycle to a temperature between 360°C and 380°C (680-716°F).

During sintering, the individual PTFE particles fuse together, creating a strong, solid mass without actually melting the material. This molecular bonding is what gives the final part its strength and unique properties.

Stage 4: Controlled Cooling

After sintering, the component is cooled in a controlled manner. The rate of cooling is crucial as it affects the crystallinity of the PTFE, which in turn influences properties like hardness, wear resistance, and dimensional stability.

Material Blends and Component Design

The compression molding process is highly adaptable, allowing for significant customization of both the material composition and the final part geometry.

Blending for Performance

Pure PTFE is rarely used. More often, the powder is blended with additives or fillers to enhance specific characteristics.

For example, material blends can be formulated to be equivalent to specific grades like Rulon J or Rulon LR to achieve desired friction, wear, or load-bearing capabilities. Additives can also meet regulatory standards, such as those from the FDA.

Designing for Specific Applications

While the process is well-suited for simple shapes, it can produce a variety of bushing designs.

Common shapes include simple cylindrical bushes and flanged bushes. The process can also accommodate custom geometries tailored to unique hardware or assembly requirements.

Understanding the Process Implications

The nature of compression molding has direct consequences on the final product, which engineers and designers must consider.

Impact on Dimensional Tolerance

Because the part is not injection molded from a liquid, achieving extremely tight tolerances directly from the mold can be challenging. Sintering and cooling can cause minor, predictable changes in dimensions.

For applications requiring very high precision, a secondary machining step is often performed on the sintered bushing.

Suitability for Component Geometry

Compression molding is ideal for producing parts with relatively uniform wall thicknesses and simpler geometries, like rings and cylinders.

Complex features like sharp internal corners or drastic changes in thickness can create challenges with powder flow and density, potentially affecting the integrity of the final part.

Making the Right Choice for Your Application

Use the manufacturing process to inform your design and material selection.

- If your primary focus is wear resistance or load-bearing: Specify a blended PTFE material with a filler like bronze, carbon, or glass.

- If your primary focus is a specific geometry: Engage with the manufacturer early to ensure your design is compatible with the compression molding process, especially for flanged or custom shapes.

- If your primary focus is cost-effective production of standard shapes: This process is highly efficient for producing simple cylindrical bushes in large volumes.

Understanding how a PTFE bushing is made empowers you to specify a component that is perfectly suited to its intended function.

Summary Table:

| Stage | Key Process | Details |

|---|---|---|

| 1. Powder Charging | Uniformly fill mold | Ensures consistent density with PTFE or filler blends. |

| 2. Compression | High-pressure forming | Creates a 'preform' at 10-100 MPa pressure. |

| 3. Sintering | High-temperature fusion | Heated to 360-380°C to bond particles without melting. |

| 4. Cooling | Controlled rate cooling | Determines final crystallinity and dimensional stability. |

Need a custom PTFE bushing for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision compression molding process ensures your bushes meet exact specifications for wear resistance, load-bearing, and complex geometries—from prototypes to high-volume orders.

Contact us today to discuss your project and receive a quote for custom PTFE solutions that deliver reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance