Yes, PTFE sheets are highly customizable. Not only can they be ordered in specific custom dimensions directly from suppliers, but standard sheets can also be easily trimmed to a desired size using simple tools like scissors for many applications.

The true value of PTFE lies in its remarkable adaptability. Beyond simple sizing, it can be tailored in thickness, form, and even surface chemistry to meet precise engineering and industrial requirements.

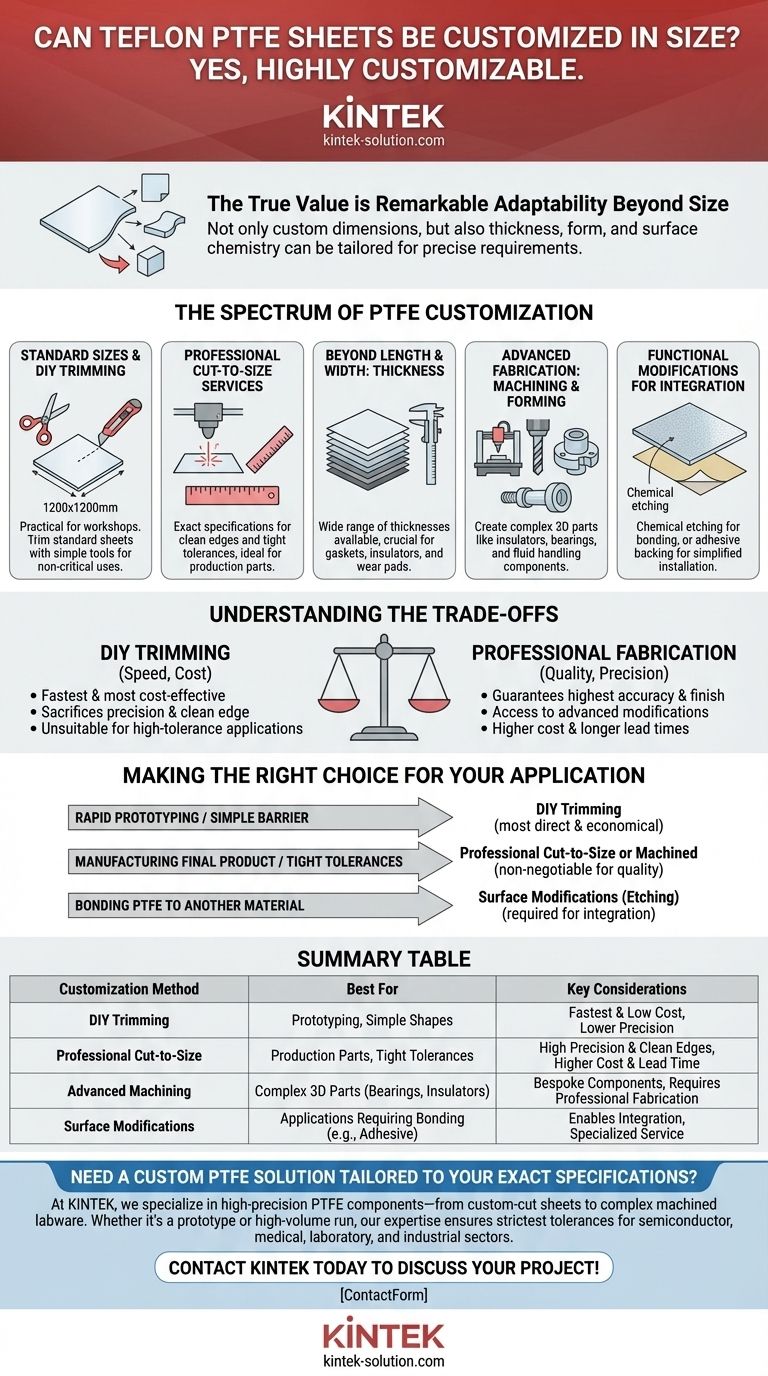

The Spectrum of PTFE Customization

Understanding the different ways PTFE can be modified is key to leveraging its full potential for your project. The options range from simple manual adjustments to complex industrial fabrication.

Standard Sizes and DIY Trimming

For many workshops and prototyping scenarios, starting with a standard sheet is the most practical approach. Suppliers typically offer common sizes like 1200x1200 mm or 1500x1500 mm.

For non-critical applications, these sheets can be cut down to your required dimensions using a sharp utility knife or heavy-duty scissors.

Professional Cut-to-Size Services

When precision is paramount, suppliers can provide PTFE sheets cut to your exact specifications. This method ensures clean, accurate edges and tight tolerances that are difficult to achieve by hand.

This is the preferred option for production parts or when the final fit and finish are critical.

Beyond Length and Width: Thickness

Customization is not limited to two dimensions. PTFE sheets are available in a wide range of thicknesses, and this parameter is just as crucial as length and width for performance in applications like gaskets, insulators, or wear pads.

Advanced Fabrication: Machining and Forming

PTFE's versatility extends to creating complex three-dimensional parts. It can be machined, drilled, and milled to produce custom components like insulators, bearings, and fluid handling parts.

This capability allows for the creation of bespoke parts tailored to a specific piece of equipment or engineering challenge.

Functional Modifications for Integration

For applications requiring PTFE to be part of a larger assembly, its surface can be modified. One common process is chemical etching on one side, which alters the non-stick surface to allow for effective bonding with adhesives.

Similarly, features like an adhesive backing can be added to parts like washers or strips to simplify installation.

Understanding the Trade-offs

Choosing the right customization method involves balancing speed, cost, and precision. Each approach comes with its own set of considerations.

DIY Trimming: Speed vs. Precision

Cutting a standard sheet yourself is the fastest and most cost-effective solution for simple shapes and prototypes.

However, it sacrifices the precision and clean edge quality of professional cutting. This method is often unsuitable for high-tolerance or high-performance applications.

Professional Fabrication: Quality vs. Cost

Ordering custom-cut or machined parts guarantees the highest level of accuracy and a professional finish. This path also provides access to advanced modifications like etching.

The trade-off is typically a higher cost and longer lead times compared to buying a standard sheet off the shelf.

Making the Right Choice for Your Application

Your project's specific requirements will determine the best path forward for customizing your PTFE material.

- If your primary focus is rapid prototyping or a simple protective barrier: Trimming a standard-sized sheet yourself is the most direct and economical solution.

- If your primary focus is manufacturing a final product with tight tolerances: Ordering professionally cut-to-size or machined parts is non-negotiable for quality and consistency.

- If your primary focus is bonding the PTFE to another material: You must request a sheet that has been specially prepared with chemical etching on one side.

Ultimately, PTFE's capacity for customization is a core reason for its widespread use across countless industries.

Summary Table:

| Customization Method | Best For | Key Considerations |

|---|---|---|

| DIY Trimming | Prototyping, simple shapes, non-critical uses | Fastest & most cost-effective; lower precision |

| Professional Cut-to-Size | Production parts, tight tolerances | High precision & clean edges; higher cost & lead time |

| Advanced Machining | Complex 3D parts (bearings, insulators) | Creates bespoke components; requires professional fabrication |

| Surface Modifications | Applications requiring bonding (e.g., adhesive backing) | Enables integration into assemblies; a specialized service |

Need a custom PTFE solution tailored to your exact specifications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—from custom-cut sheets and seals to complex machined labware and liners. Whether you need a simple prototype or a high-volume production run, our expertise ensures your PTFE parts meet the strictest tolerances and performance requirements for the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key benefits of PTFE energized seals for the aerospace industry? Unmatched Reliability in Extreme Environments

- Why are PTFE bearing pads essential? Ensure Structural Safety and Longevity with Low-Friction Solutions

- Can Medical Grade PTFE Liners be customized for specific needs? Tailor Size, Thickness & Surface for Your Device

- What are the benefits of integrating PTFE into piping support systems? Reduce Friction, Corrosion & Maintenance

- What is the role of bearing pads in civil engineering? The Critical Interface for Structural Integrity

- What industries benefit most from custom PTFE parts? Solve Extreme Environment Challenges

- What makes PTFE gland packings suitable for demanding sealing conditions? Unmatched Chemical & Thermal Resistance