Yes, absolutely. Medical Grade Polytetrafluoroethylene (PTFE) liners are not only customizable but are designed with customization in mind. Key parameters such as size, wall thickness, and surface configuration can be precisely engineered to meet the stringent requirements of specific medical devices, directly influencing their performance and safety profile.

The true value of Medical Grade PTFE lies not just in its inherent properties but in its profound adaptability. This allows engineers to move beyond off-the-shelf components and create highly tailored solutions that enhance device function and improve patient outcomes.

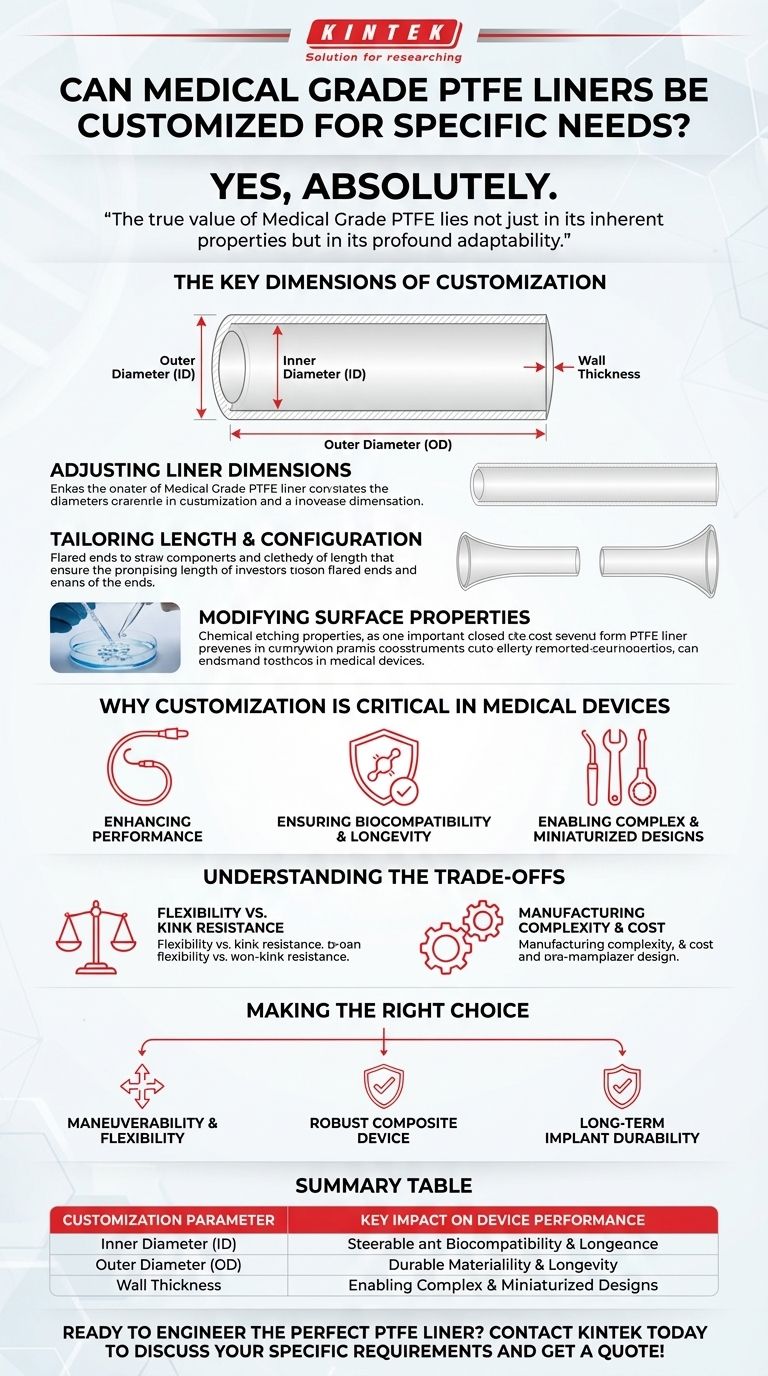

The Key Dimensions of Customization

Understanding the specific ways PTFE liners can be modified is the first step in leveraging their full potential for a medical device application.

Adjusting Liner Dimensions

The most fundamental customizations involve the physical dimensions of the liner. This includes the inner diameter (ID), outer diameter (OD), and the resulting wall thickness.

These parameters are not arbitrary; they directly control critical performance characteristics like the flexibility, pushability, and kink resistance of devices such as catheters and endoscopes.

Tailoring Length and Configuration

Beyond simple dimensions, liners can be cut to precise lengths to match device requirements. They can also be manufactured with specific features, such as flared or flanged ends, to aid in assembly and secure placement within a larger device construct.

Modifying Surface Properties

For devices that require bonding the PTFE liner to other materials (like a catheter jacket), the surface can be altered. A common and critical customization is chemical etching on one side of the liner.

This process modifies the naturally lubricious, non-stick surface of PTFE, creating a bondable exterior without compromising the slickness of the interior lumen.

Why Customization is Critical in Medical Devices

Customization isn't just about fitting a part into a space; it's about optimizing the entire function of the medical instrument.

Enhancing Device Performance

A liner with a customized, ultra-thin wall can drastically improve the flexibility of a steerable catheter, allowing it to navigate complex vasculatures. Conversely, a thicker wall can provide the necessary column strength for guide catheters that need to deliver other devices.

Ensuring Biocompatibility and Longevity

The inherent durability of PTFE, with its resistance to chemicals and low water absorption, makes it ideal for long-term applications. Customizing the fit ensures there are no points of excessive stress or wear, preserving the material's integrity and safety profile over the device's lifespan.

Enabling Complex and Miniaturized Designs

Modern medical devices are becoming increasingly small and complex. The ability to specify exact liner dimensions is a key enabler for innovation, allowing designers to create next-generation tools that are less invasive and more effective.

Understanding the Trade-offs

While customization offers significant advantages, it's essential to approach it with a clear understanding of the engineering trade-offs involved.

Flexibility vs. Kink Resistance

Reducing wall thickness to increase flexibility can have a corresponding effect on the liner's resistance to kinking. This is a critical balance that must be carefully engineered based on the device's intended anatomical path and function.

Manufacturing Complexity and Cost

Highly specialized customizations, such as multi-lumen extrusions or advanced surface treatments, will naturally increase manufacturing complexity. This can impact both the final cost per unit and production lead times.

Impact on Material Integrity

Any modification, whether dimensional or a surface treatment like etching, must be carefully controlled. The goal is to achieve the desired performance characteristic without compromising the fundamental properties—like chemical resistance and durability—that make PTFE a preferred medical-grade material.

Making the Right Choice for Your Application

Your specific design goal will determine which customization parameters are most critical for your project.

- If your primary focus is maneuverability and flexibility: Concentrate on optimizing wall thickness and material durometer to achieve the ideal balance for your device's trackability.

- If your primary focus is creating a robust composite device: Explore chemical etching to ensure a strong, reliable bond between the PTFE liner and other polymer or braided layers.

- If your primary focus is long-term implant durability: Prioritize a configuration that minimizes mechanical stress and ensures the liner's dimensions are perfectly matched to its housing.

Ultimately, strategic customization transforms Medical Grade PTFE from a simple material into a precisely engineered component that is fundamental to your device's success.

Summary Table:

| Customization Parameter | Key Impact on Device Performance |

|---|---|

| Dimensions (ID/OD/Wall Thickness) | Controls flexibility, pushability, and kink resistance. |

| Length & End Configuration | Ensures precise fit and aids in assembly (e.g., flared ends). |

| Surface Properties (e.g., Etching) | Enables strong bonding to other materials while maintaining a slick interior. |

Ready to engineer the perfect PTFE liner for your medical device?

At KINTEK, we specialize in precision-customizing Medical Grade PTFE components like liners, seals, and labware. Whether you need a prototype for R&D or high-volume production for the semiconductor, medical, or laboratory industries, our expertise ensures your liners are optimized for performance, safety, and durability.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance