The primary benefits of integrating PTFE into piping support systems are a dramatic reduction in friction, the prevention of galvanic corrosion, and the absorption of vibration. This integration leads directly to lower maintenance costs, enhanced operational reliability, and a significantly longer lifespan for the entire piping infrastructure.

By acting as a protective, low-friction barrier between the pipe and its support structure, PTFE fundamentally isolates the pipe from the primary mechanical and chemical stresses that cause wear and failure over time.

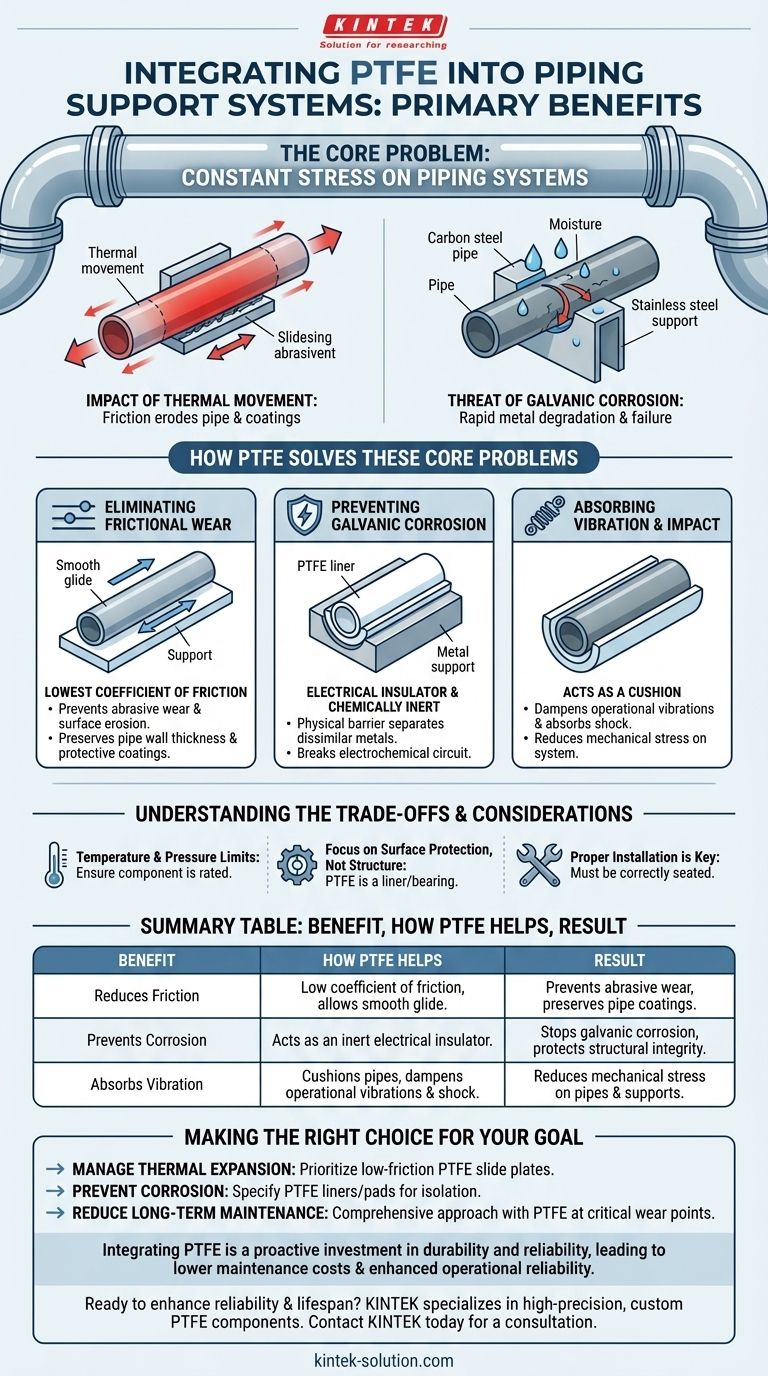

The Core Problem: Constant Stress on Piping Systems

Piping systems are not static. They are constantly subjected to subtle but powerful forces that can lead to premature failure if not managed correctly. Understanding these forces is key to appreciating the value of PTFE.

The Impact of Thermal Movement

Pipes expand and contract as the temperature of the fluid inside them—or the ambient environment—changes. This movement, while often small, creates a sliding action against their support structures.

When a metal pipe slides directly against a metal support, the resulting friction acts like sandpaper, slowly eroding the pipe's surface and protective coatings.

The Threat of Galvanic Corrosion

When two dissimilar metals (like a carbon steel pipe and a stainless steel support) are in direct contact in the presence of an electrolyte (like moisture), an electrochemical reaction occurs.

This galvanic corrosion causes one of the metals to degrade rapidly, compromising the structural integrity of the pipe or the support and creating a critical failure point.

How PTFE Solves These Core Problems

Polytetrafluoroethylene (PTFE) is a uniquely suited material for addressing these challenges. It is not used for its structural strength, but for its exceptional surface and chemical properties when placed at the interface between the pipe and its support.

Eliminating Frictional Wear

PTFE has one of the lowest coefficients of friction of any solid material. Placing a PTFE liner or slide plate at the contact point allows the pipe to glide smoothly during thermal expansion and contraction.

This near-frictionless movement prevents the abrasive wear and surface erosion that would otherwise occur, preserving the pipe's wall thickness and protective coatings.

Preventing Galvanic Corrosion

PTFE is an excellent electrical insulator and is chemically inert. By serving as a physical barrier, it completely separates the pipe from the metal support.

This separation breaks the electrochemical circuit required for galvanic corrosion to occur, effectively protecting the system from this common and destructive form of degradation.

Absorbing Vibration and Impact

Piping systems are subject to operational vibrations. PTFE liners act as a cushion, dampening these vibrations and absorbing the shock of any minor impacts.

This dampening effect reduces mechanical stress on both the pipe and the support structure, preserving their long-term integrity and reducing the need for costly maintenance.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. Its proper application requires an understanding of its limitations.

Temperature and Pressure Limits

PTFE has a broad operating temperature range, but it is not infinite. Engineers must ensure the specified PTFE component is rated for the system's maximum and minimum operating temperatures and pressures.

Focus on Surface Protection, Not Structure

It is critical to remember that PTFE is a liner or bearing surface, not a structural component. The mechanical load of the piping system must be handled by the steel support structure (e.g., clamps, hangers, or shoes).

Proper Installation is Key

The benefits of PTFE are only realized if it is installed correctly. A damaged or improperly seated PTFE liner or slide plate can fail to provide the necessary separation, negating its protective qualities.

Making the Right Choice for Your Goal

Integrating PTFE is a strategic decision. Use your primary objective to guide its application.

- If your primary focus is managing thermal expansion: Prioritize the use of low-friction PTFE slide plates at key support points to allow for unimpeded movement.

- If your primary focus is preventing corrosion: Specify PTFE liners or pads to isolate pipes from their supports, especially where dissimilar metals are present.

- If your primary focus is reducing long-term maintenance: A comprehensive approach using PTFE at all critical wear points is the most effective investment in system longevity.

Ultimately, integrating PTFE into pipe supports is a proactive investment in the durability and reliability of your entire system.

Summary Table:

| Benefit | How PTFE Helps | Result |

|---|---|---|

| Reduces Friction | Low coefficient of friction allows pipes to glide smoothly. | Prevents abrasive wear, preserves pipe coatings. |

| Prevents Corrosion | Acts as an inert electrical insulator between dissimilar metals. | Stops galvanic corrosion, protects structural integrity. |

| Absorbs Vibration | Cushions pipes, dampening operational vibrations and shock. | Reduces mechanical stress on pipes and supports. |

Ready to enhance the reliability and lifespan of your piping systems?

KINTEK specializes in manufacturing high-precision, custom PTFE components—including liners, slide plates, and pads—for pipe support applications. Our products are designed to isolate pipes from damaging friction and corrosion, directly leading to lower maintenance costs and greater operational uptime.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver the precision and quality your critical systems demand.

Contact KINTEK today for a consultation on your specific piping support challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance