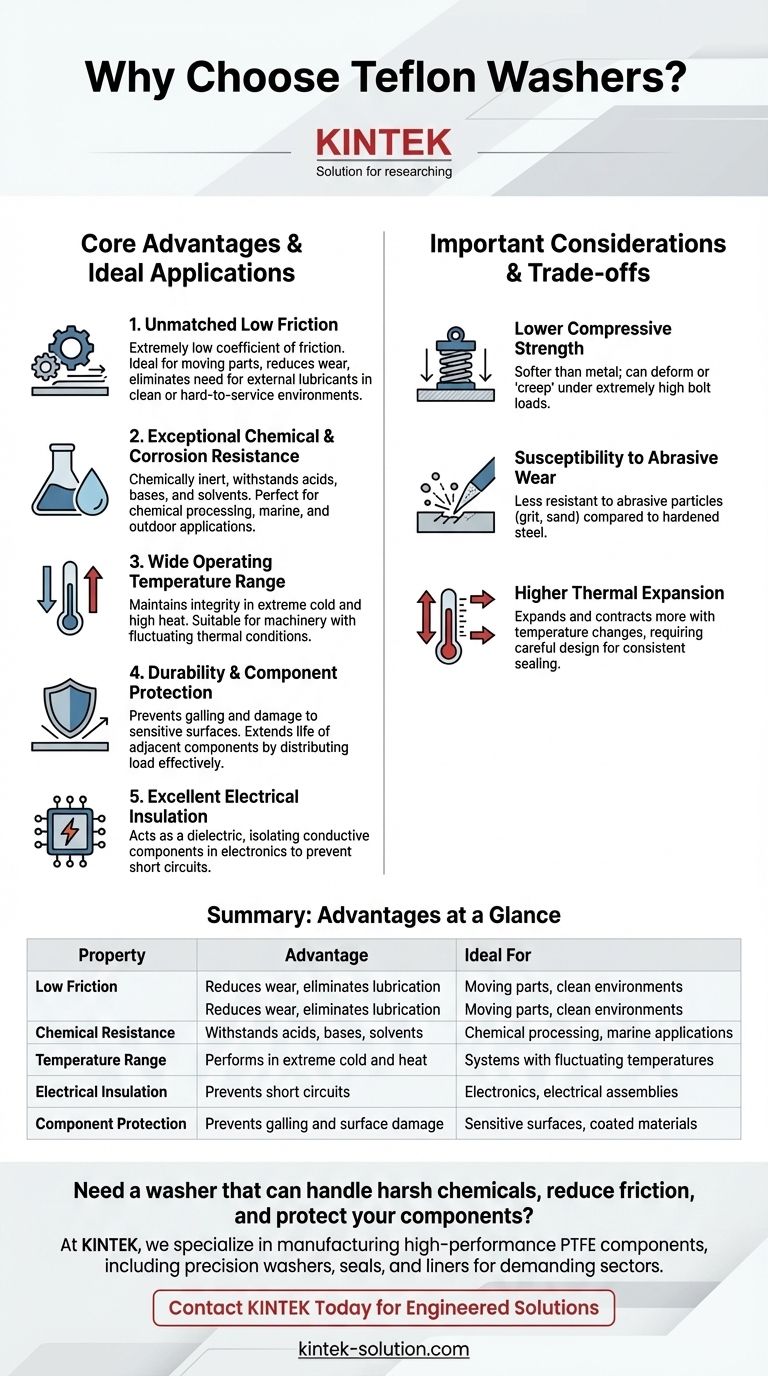

The primary reason to choose Teflon washers is their unique combination of properties that solve problems other materials cannot. They are chosen for their extreme chemical resistance, naturally low friction that requires no external lubrication, and their ability to protect sensitive components from wear and corrosion in a wide range of operating temperatures.

At its core, the decision to use a Teflon washer is not just about finding a spacer; it's about engineering a solution for environments where friction, chemical attack, or corrosion would cause metal or rubber components to fail.

The Core Properties Defining Teflon (PTFE) Washers

To understand why Teflon, or Polytetrafluoroethylene (PTFE), is specified, we must look at its fundamental material characteristics. Each property addresses a distinct engineering challenge.

Unmatched Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This natural "slipperiness" is a significant advantage.

This property allows moving parts to operate with minimal resistance, reducing the need for grease or oil. This is critical in clean environments or hard-to-service assemblies.

The low friction also dramatically reduces wear and tear on adjacent metal surfaces, extending the operational life of the entire assembly.

Exceptional Chemical & Corrosion Resistance

Teflon is chemically inert, meaning it does not react with most substances. This makes it an ideal choice for use in aggressive environments.

It can withstand exposure to a wide array of acids, bases, and solvents that would quickly degrade metals or other plastics.

Furthermore, it is completely water-resistant, which prevents rust and corrosion from forming on the components it seals and separates.

Wide Operating Temperature Range

Teflon washers perform reliably across a broad spectrum of temperatures.

They maintain their integrity and key properties in extremely low-temperature applications where other materials might become brittle. They also offer good performance in high-heat situations.

This versatility makes them suitable for machinery and systems that operate in extreme or fluctuating environmental conditions.

Durability and Component Protection

While metal washers provide high compressive strength, they can also gall, scratch, or damage the surfaces they are tightened against.

Teflon washers create a durable, yet forgiving, barrier. They effectively distribute load while preventing damage to sensitive surfaces, coatings, or softer materials.

This low-wear characteristic ensures a long service life for both the washer and the components it is installed with.

Excellent Electrical Insulation

Teflon is an excellent electrical insulator, also known as a dielectric.

This property is crucial in electronics and electrical assemblies where it is necessary to isolate conductive components, like screws and chassis, to prevent short circuits.

Understanding the Trade-offs

No material is perfect for every scenario. Acknowledging Teflon's limitations is key to using it effectively.

Lower Compressive Strength

Compared to steel, bronze, or other metal washers, Teflon is a much softer material.

Under extremely high bolt loads, a Teflon washer can deform or "creep" over time, potentially leading to a loss of clamping force.

Susceptibility to Abrasive Wear

While Teflon has very low frictional wear, it is not as resistant to abrasive particles as hardened steel.

In environments with significant grit, sand, or other abrasive contaminants, the washer may wear down more quickly than a metallic alternative.

Higher Thermal Expansion

Teflon expands and contracts with temperature changes more than metals do.

In applications with extreme temperature swings, this characteristic must be considered during design to ensure that a consistent seal and load are maintained.

Making the Right Choice for Your Application

Choosing the correct washer material requires matching its properties to your primary goal.

- If your primary focus is reducing friction and wear in moving parts: Teflon's natural slipperiness is ideal for protecting components and ensuring smooth operation without lubricants.

- If your primary focus is resistance to harsh chemicals or corrosion: Teflon's inertness makes it a superior choice for sealing in chemical processing, marine, or outdoor applications.

- If your primary focus is electrical isolation: Teflon's dielectric properties provide a reliable barrier between conductive screws, fasteners, and circuits.

- If your primary focus is managing extremely high clamping loads: You may need to consider a metallic washer, as Teflon can deform under the intense compressive stress.

Ultimately, selecting a Teflon washer is a strategic decision for applications where chemical stability and low friction are paramount to long-term success.

Summary Table:

| Property | Advantage | Ideal For |

|---|---|---|

| Low Friction | Reduces wear, eliminates lubrication | Moving parts, clean environments |

| Chemical Resistance | Withstands acids, bases, solvents | Chemical processing, marine applications |

| Temperature Range | Performs in extreme cold and heat | Systems with fluctuating temperatures |

| Electrical Insulation | Prevents short circuits | Electronics, electrical assemblies |

| Component Protection | Prevents galling and surface damage | Sensitive surfaces, coated materials |

Need a washer that can handle harsh chemicals, reduce friction, and protect your components?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision washers, seals, and liners. Our expertise ensures you get a solution tailored to the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability.

Contact KINTEK today to discuss your specific requirements and get a solution engineered for success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F