To put it simply, UV resistance is critical for PTFE Teflon washers because it prevents them from degrading when exposed to sunlight or other sources of ultraviolet radiation. This property is non-negotiable for outdoor applications, as it ensures the washer does not become brittle, crack, or fail, thereby maintaining the integrity and performance of the entire assembly over its intended lifespan.

The core issue isn't just about the washer itself, but the system it protects. A lack of UV resistance leads to material failure, which in turn causes loose connections, leaks, and compromised seals, potentially leading to catastrophic failure in the larger assembly.

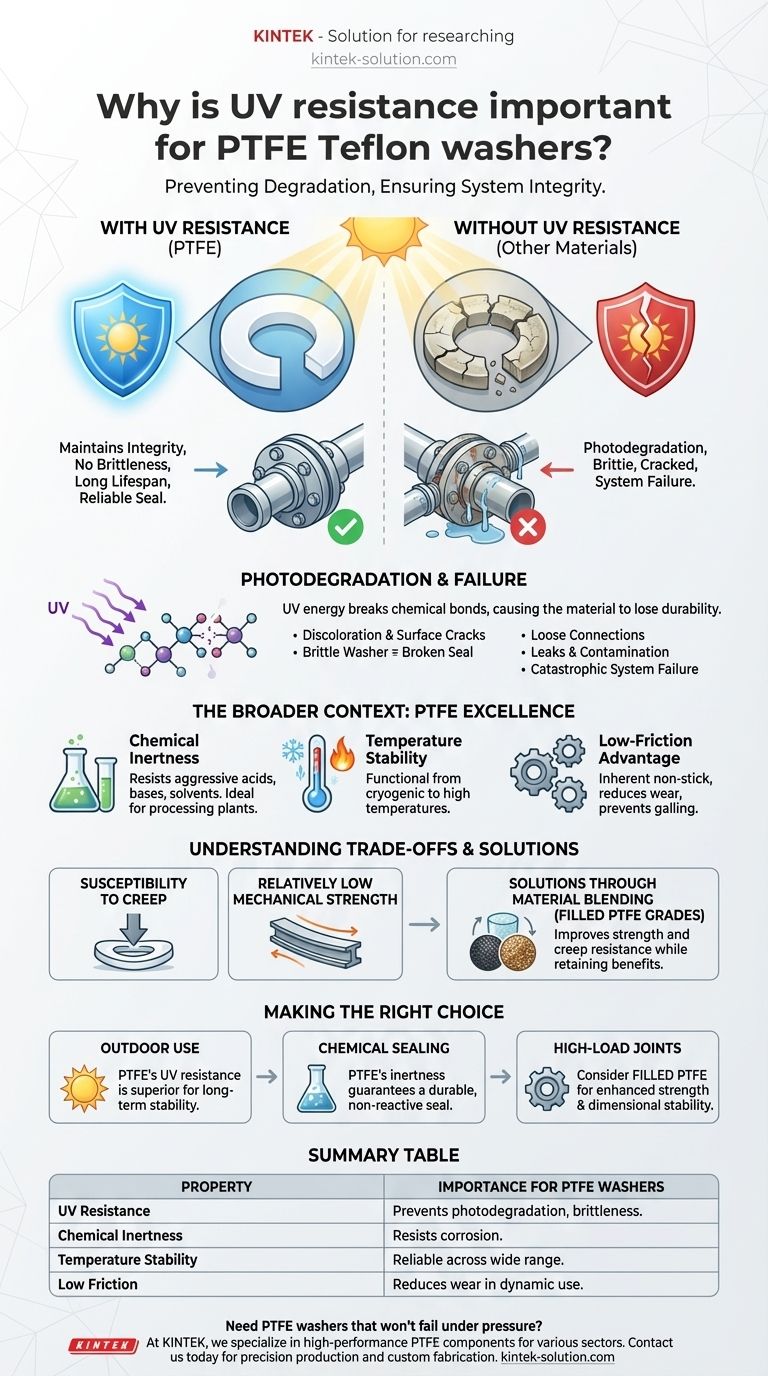

What Happens When Materials Lack UV Resistance?

When a material isn't resistant to ultraviolet light, it undergoes a process of degradation that fundamentally changes its physical properties, rendering it useless for its intended purpose.

The Process of Photodegradation

UV radiation contains enough energy to break the chemical bonds within a polymer's structure. This process, known as photodegradation, causes the material to lose its durability.

Over time, this breakdown results in visible and structural damage. The material can become discolored, brittle, and develop surface cracks, severely compromising its strength.

The Consequence of Failure

For a component like a washer, this degradation is a critical failure. A brittle washer can no longer provide a reliable seal or maintain the correct clamping force in a bolted joint.

This can lead to leaks in fluid systems, loss of tension in mechanical assemblies, and an entry point for contaminants. Ultimately, the failure of a simple washer can jeopardize the function of a much more complex and expensive piece of equipment.

The Broader Context: Why PTFE Excels in Harsh Environments

PTFE's value extends far beyond its UV resistance. Its suitability for demanding applications comes from a unique combination of properties that make it exceptionally durable.

Unmatched Chemical Inertness

PTFE washers exhibit tremendous resistance to a wide spectrum of chemicals, including aggressive acids, bases, and solvents.

Their virtually inert nature prevents them from reacting with or being degraded by corrosive substances, making them ideal for chemical processing plants, laboratories, and industrial settings.

Superior Temperature Stability

PTFE maintains its properties across an exceptionally wide temperature range. It remains reliable and functional in cryogenic conditions as well as in high-temperature environments, a versatility few other materials can match.

The Low-Friction Advantage

With one of the lowest coefficients of friction of any solid material, PTFE is inherently non-stick. This reduces wear in dynamic applications and prevents galling between surfaces, ensuring smooth operation.

Understanding the Trade-offs of PTFE

While PTFE is an exceptional material, no single solution is perfect. A true technical assessment requires acknowledging its limitations.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, pure PTFE can slowly deform over time. This phenomenon, known as creep, can result in a loss of bolt tension in critical sealing applications.

Relatively Low Mechanical Strength

Compared to other engineering plastics like PEEK or Nylon, virgin PTFE is a relatively soft material. It has lower tensile strength and abrasion resistance, making it less suitable for high-load structural components.

Solutions Through Material Blending

To counteract these limitations, PTFE is often blended with fillers like glass, carbon, or bronze. These filled PTFE grades offer significantly improved mechanical strength and creep resistance while retaining most of the base material's benefits.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to the primary demands of your application.

- If your primary focus is outdoor use or sunlight exposure: PTFE's inherent UV resistance makes it a superior and reliable choice, ensuring long-term stability.

- If your primary focus is sealing aggressive chemicals: PTFE's chemical inertness is its most valuable asset, guaranteeing a non-reactive and durable seal.

- If your primary focus is a high-load mechanical joint: Be cautious of pure PTFE's potential for creep and consider a filled PTFE grade for enhanced strength and dimensional stability.

Ultimately, understanding the full profile of PTFE—its powerful resistances and its known limitations—is the key to deploying it effectively.

Summary Table:

| Property | Importance for PTFE Washers |

|---|---|

| UV Resistance | Prevents photodegradation, brittleness, and cracking from sunlight exposure. |

| Chemical Inertness | Resists corrosion from acids, bases, and solvents. |

| Temperature Stability | Performs reliably across a wide range of cryogenic and high-temperature conditions. |

| Low Friction | Reduces wear and prevents galling in dynamic applications. |

Need PTFE washers that won't fail under pressure?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals and washers, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component perfectly tailored to withstand your specific environmental challenges, including UV exposure.

Contact us today to discuss your application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability