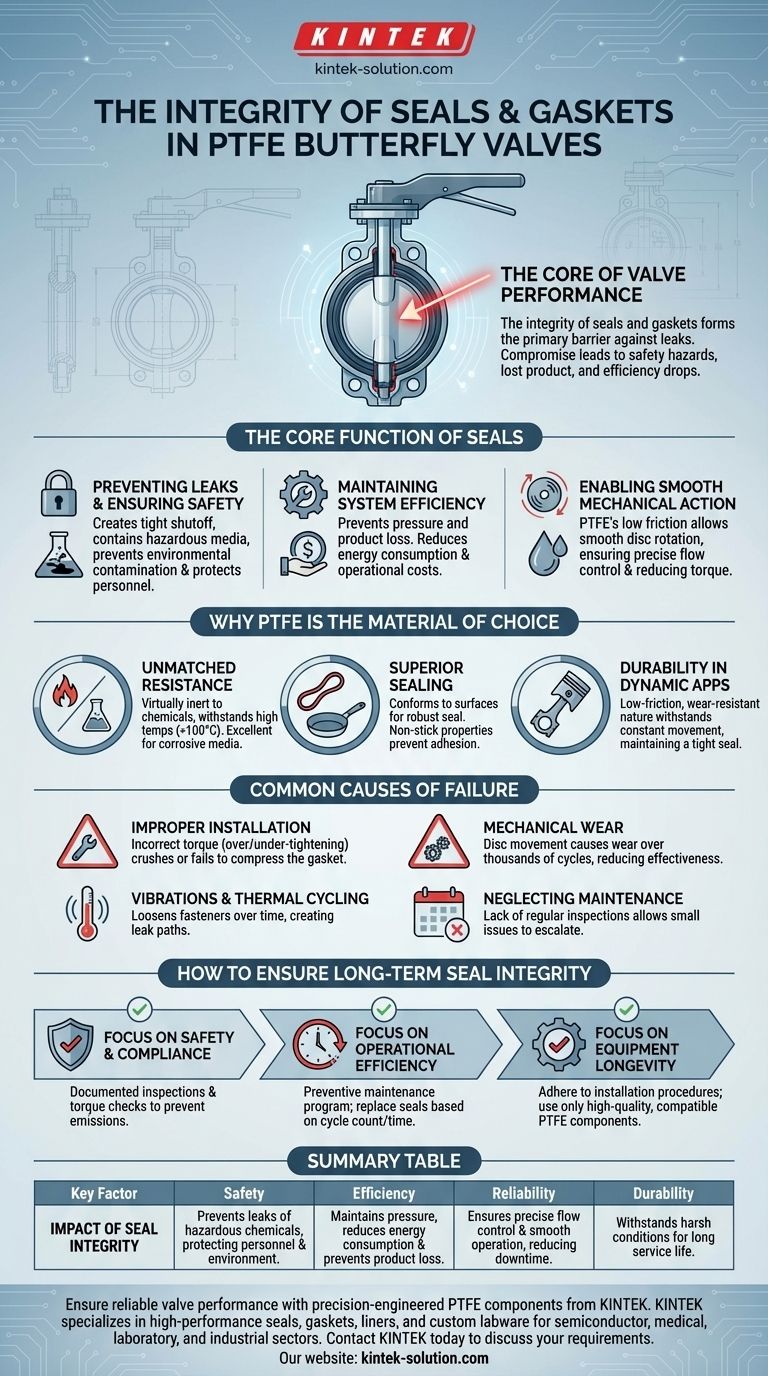

The integrity of seals and gaskets in a PTFE butterfly valve is paramount because these components form the primary barrier against system leaks. A compromised seal directly undermines the valve's core purpose, leading to safety hazards, lost product, and a significant drop in operational efficiency.

A valve's performance is not defined by its metal body, but by the reliability of its soft components. The integrity of PTFE seals and gaskets is what allows the valve to safely control flow, especially under the harsh chemical and thermal conditions where they are most needed.

The Core Function of Seals in Valve Operation

A butterfly valve's design relies entirely on the precise contact between the valve disc and a soft seat or seal. The integrity of this contact point dictates the valve's ability to perform its function.

Preventing Leaks and Ensuring Safety

The most critical role of a seal is to create a tight shutoff, preventing the process media from escaping. This is vital for containing hazardous chemicals, preventing environmental contamination, and protecting personnel from exposure.

Maintaining System Efficiency

Leaks, even minor ones, represent a loss of pressure and product. This forces pumps and other equipment to work harder to maintain system parameters, consuming more energy and increasing operational costs. A secure seal ensures the system runs as designed.

Enabling Smooth Mechanical Action

PTFE's extremely low coefficient of friction is a key advantage. It allows the valve disc to rotate smoothly against the seal without sticking or galling, ensuring precise flow control and reducing the torque required from the actuator.

Why PTFE is the Material of Choice

Polytetrafluoroethylene (PTFE) is not chosen by accident. Its unique combination of properties makes it exceptionally well-suited for the demanding role of a valve seal in challenging industrial environments.

Unmatched Chemical and Thermal Resistance

PTFE is virtually inert to most industrial chemicals and can withstand a wide range of service temperatures, often exceeding 100°C. This makes it a reliable choice for sealing corrosive media that would quickly degrade other materials.

Superior Sealing Properties

The material possesses good elasticity, allowing it to conform to the metal surfaces of the valve body and disc to create a robust, tight seal. Its non-stick nature also prevents process media from adhering to it, which could otherwise compromise the seal over time.

Durability in Dynamic Applications

In components like valve stem packing, the seal must withstand constant movement. PTFE’s low-friction, wear-resistant nature ensures it maintains a tight seal around the moving stem, preventing leaks while allowing for smooth actuation.

Common Causes of Seal and Gasket Failure

Understanding why seals fail is the first step toward preventing it. While PTFE is a robust material, it is not immune to a few common points of failure that can compromise its integrity.

Improper Installation and Torque

The most frequent cause of premature failure is incorrect installation. Over-tightening or under-tightening flange bolts can crush a gasket or fail to compress it properly. Following precise torque specifications is essential for creating a secure, lasting seal.

Mechanical Wear and Tear

Every time a valve opens or closes, the disc edge moves across the seal. Over thousands of cycles, this natural mechanical action causes wear, gradually reducing the seal's effectiveness.

Vibrations and Thermal Cycling

System vibrations and frequent temperature changes can cause fasteners to loosen over time. This loss of compression on the gasket can create a leak path, even if the gasket material itself is not damaged.

Neglecting Preventive Maintenance

Seals and gaskets are not permanent components. A lack of regular and preventive maintenance allows small issues to escalate into significant failures, leading to unexpected and costly downtime.

How to Ensure Long-Term Seal Integrity

A proactive approach to maintenance and installation is the best way to maximize the performance and lifespan of your PTFE valve seals.

- If your primary focus is safety and compliance: Prioritize a documented schedule of regular inspections and torque checks to prevent fugitive emissions and ensure a safe operating environment.

- If your primary focus is operational efficiency: Implement a preventive maintenance program to replace seals based on cycle count or time-in-service to avoid unexpected and costly system downtime.

- If your primary focus is equipment longevity: Insist on strict adherence to manufacturer installation procedures and use only high-quality, compatible PTFE components for any replacements.

Ultimately, treating your valve's seals and gaskets as critical engineered components is the key to a reliable, efficient, and safe process.

Summary Table:

| Key Factor | Impact of Seal Integrity |

|---|---|

| Safety | Prevents leaks of hazardous chemicals, protecting personnel and the environment. |

| Efficiency | Maintains system pressure, reduces energy consumption, and prevents product loss. |

| Reliability | Ensures precise flow control and smooth mechanical operation, reducing downtime. |

| Durability | Withstands harsh chemical, thermal, and mechanical conditions for long service life. |

Ensure your valves perform reliably with precision-engineered PTFE components from KINTEK.

KINTEK specializes in manufacturing high-performance PTFE seals, gaskets, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to deliver components that guarantee the integrity your critical applications demand, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can enhance your system's safety, efficiency, and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability