At its core, Teflon is used in hoses for its exceptional ability to perform reliably under extreme conditions where other materials would quickly degrade. Its unique combination of properties—chemical inertness, extreme temperature tolerance, and physical strength—makes it the superior choice for critical applications involving aggressive fluids, high pressures, or intense heat.

The decision to use a Teflon (PTFE) hose is not about a single feature, but about ensuring operational integrity. It is chosen for environments where failure is not an option, as it provides a stable and resilient conduit for fluids that would destroy rubber or plastic.

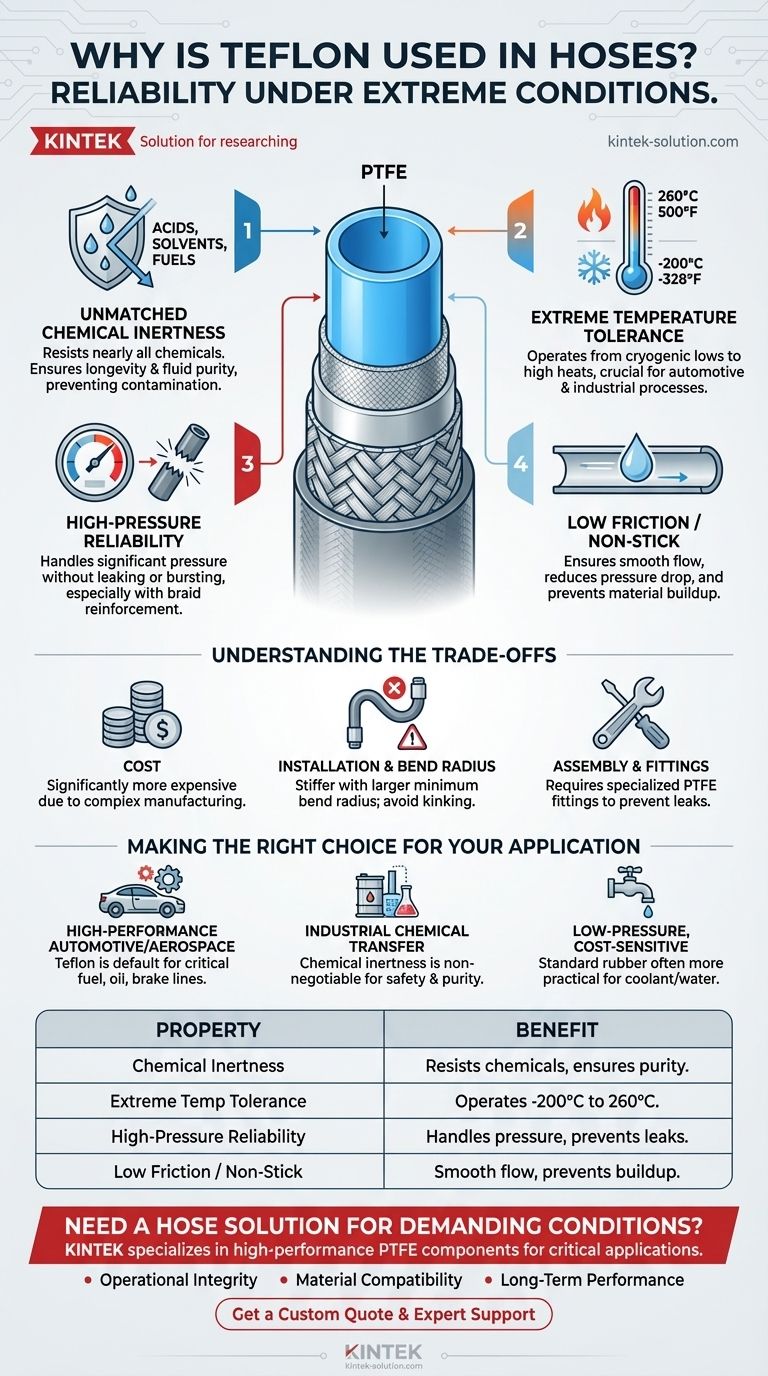

The Foundational Properties of Teflon (PTFE) Hoses

To understand why Teflon is specified for demanding jobs, we must look at its core material characteristics. Each property solves a specific engineering challenge.

Unmatched Chemical Inertness

Teflon, technically Polytetrafluoroethylene (PTFE), is famously resistant to nearly all chemicals, acids, and solvents. This means the hose will not break down when exposed to aggressive fluids like high-performance fuels, hydraulic oils, or industrial chemicals.

This inertness ensures the longevity of the hose and prevents contamination of the fluid being transported.

Extreme Temperature Tolerance

PTFE hoses can operate across an incredibly wide temperature range, from cryogenic lows around -200°C (-328°F) to high heats of 260°C (500°F).

This makes them indispensable in applications like automotive engine bays or industrial manufacturing processes where both high and low temperature extremes are common.

High-Pressure Reliability

The high density and structural integrity of Teflon allow it to handle significant pressure without leaking, swelling, or bursting.

When combined with a stainless steel or synthetic braid, a Teflon hose becomes an incredibly robust component suitable for high-pressure hydraulic, brake, or fuel systems.

The Benefit of Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, creating a "non-stick" inner surface.

This ensures a smooth, efficient flow of fluids, reduces pressure drop across the length of the hose, and prevents material buildup on the hose's inner walls.

Understanding the Trade-offs

While Teflon offers superior performance, it's essential to understand its specific limitations to make an informed decision. No material is perfect for every scenario.

Cost Considerations

The primary trade-off is cost. Teflon hoses are significantly more expensive than their rubber or standard synthetic counterparts due to a more complex manufacturing process and higher raw material costs.

Installation and Bend Radius

While flexible, PTFE hoses can be stiffer and have a larger minimum bend radius compared to many rubber hoses. Forcing a tighter bend than specified can cause the inner tube to kink, creating a permanent flow restriction.

Assembly and Fittings

Teflon hoses require specialized fittings designed specifically for PTFE. Using incorrect fittings can easily lead to leaks at the connection point, negating the benefits of the hose material itself.

Making the Right Choice for Your Application

Selecting the correct hose material is a critical engineering decision based on the demands of the system.

- If your primary focus is high-performance automotive or aerospace: Teflon is the default choice for critical fuel, oil, and brake lines due to its unparalleled resistance to heat and aggressive fluids.

- If your primary focus is industrial chemical transfer: Teflon's chemical inertness is non-negotiable, ensuring both the purity of the product and the safety of the operation.

- If your primary focus is a low-pressure, cost-sensitive application: A standard rubber or synthetic hose is often the more practical and economical solution for tasks like coolant lines or general water transfer.

Ultimately, understanding these core material properties allows you to select a hose based on performance requirements, ensuring reliability and safety in your specific application.

Summary Table:

| Property | Benefit for Hose Applications |

|---|---|

| Chemical Inertness | Resists nearly all chemicals, acids, and solvents, ensuring longevity and fluid purity. |

| Extreme Temperature Tolerance | Operates reliably from -200°C to 260°C (-328°F to 500°F). |

| High-Pressure Reliability | Handles significant pressure without leaking or bursting, especially when braid-reinforced. |

| Low Friction / Non-Stick | Provides smooth fluid flow, reduces pressure drop, and prevents material buildup. |

Need a Hose Solution for Demanding Conditions?

When your application involves aggressive chemicals, extreme temperatures, or high pressures, a standard hose simply won't suffice. You need the proven reliability of Teflon (PTFE).

KINTEK specializes in manufacturing high-performance PTFE components, including custom hoses and liners, for the most critical applications. We serve the semiconductor, medical, laboratory, and industrial sectors, where failure is not an option. Our expertise lies in precision production and custom fabrication, from initial prototypes to high-volume orders.

Let us provide you with a hose solution that guarantees:

- Operational Integrity: Prevent costly downtime and ensure safety.

- Material Compatibility: Protect your sensitive fluids and processes.

- Long-Term Performance: Withstand the harshest environments.

Contact us today to discuss your specific requirements and discover how our custom PTFE solutions can solve your most challenging fluid transfer problems.

Get a Custom Quote & Expert Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance