At its core, Teflon is slippery because it isn't just a surface—it's a self-lubricating system. When another object slides across it, Teflon sheds an invisibly thin layer of its own material onto that object. The result is that the object isn't sliding on Teflon; rather, a thin film of Teflon is sliding across another layer of Teflon, which creates an exceptionally low-friction interaction.

The counter-intuitive secret to Teflon's slipperiness is that it's not about how objects interact with the Teflon surface. It's about how Teflon interacts with itself after transferring a microscopic film to the other object.

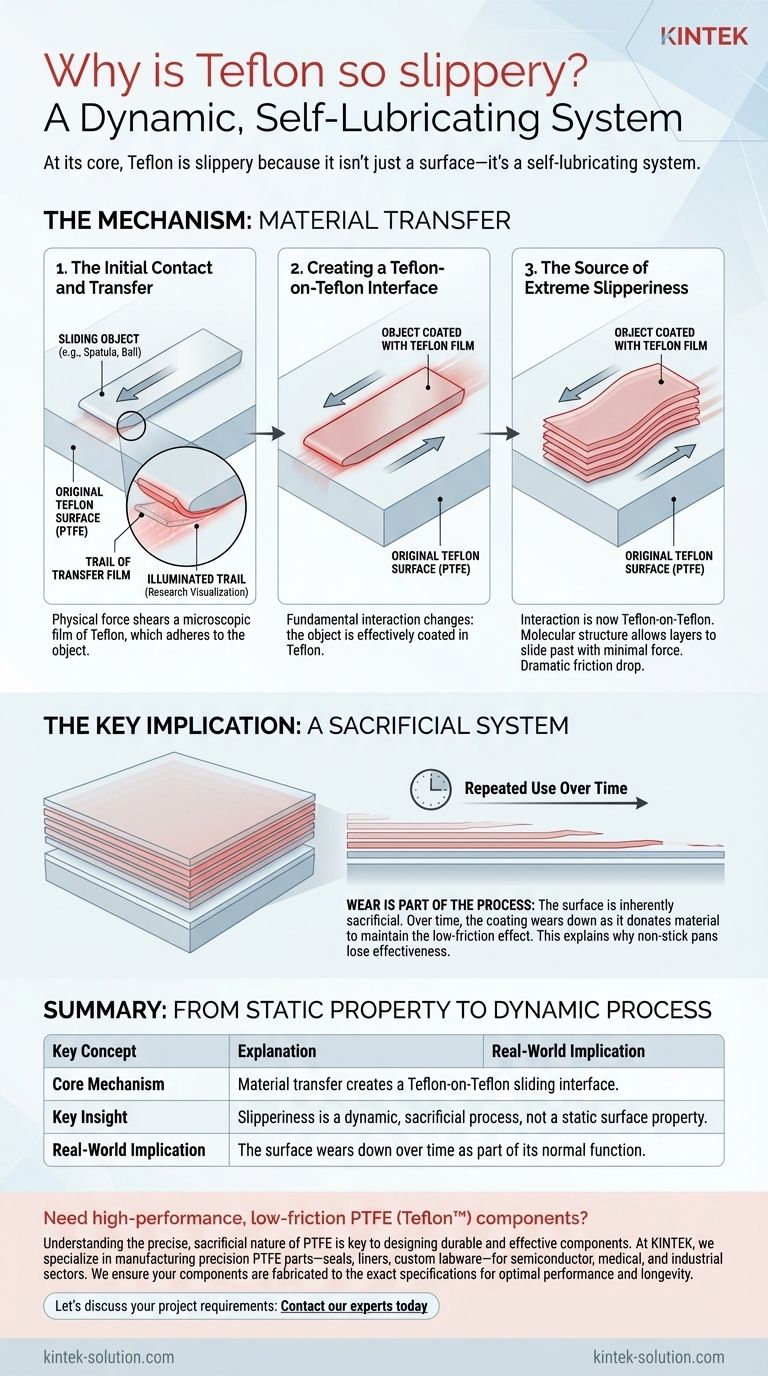

The Mechanism: How Material Transfer Creates a Low-Friction Surface

To truly understand why Teflon, or Polytetrafluoroethylene (PTFE), is so effective, we need to look beyond the static surface and examine the dynamic process that occurs during contact.

The Initial Contact and Transfer

When an object first makes contact and moves across a Teflon surface, the physical force is enough to shear off a microscopic layer of the Teflon material. This ultra-thin film then adheres to the surface of the object.

This isn't theoretical; researchers have visualized this effect directly. By dragging a Teflon ball across a glass plate coated with molecules that light up under pressure, they observed a clear, illuminated trail, proving a layer of Teflon was deposited onto the glass.

Creating a Teflon-on-Teflon Interface

Once this transfer film is in place, the fundamental interaction changes. The object's surface is now effectively coated in Teflon.

As the object continues to move, the friction is no longer between Teflon and glass, metal, or another material. It is now between the Teflon film on the object and the original Teflon surface.

The Source of Extreme Slipperiness

This Teflon-on-Teflon interaction is the key. The molecular structure of Teflon makes it very non-reactive and allows its own layers to slide past one another with minimal force. By ensuring both surfaces in contact are made of the same low-friction material, the coefficient of friction drops dramatically.

The Key Implication: A Sacrificial System

Understanding this transfer mechanism reveals a critical aspect of how Teflon functions in real-world applications. It's not a permanent, unchanging surface.

Wear is Part of the Process

The very act that makes Teflon slippery—shedding a layer of itself—means the surface is inherently sacrificial. Over time and with repeated use, the Teflon coating will wear down as it continuously donates material to create the low-friction effect.

This explains why non-stick pans eventually lose their effectiveness. Each use transfers a minuscule amount of the coating away until the underlying material is exposed.

Performance Depends on the Interaction

Teflon's slipperiness is not just a property of the material in isolation; it is the result of an interaction. The effectiveness of the lubrication depends on the successful transfer and maintenance of that thin film on the opposing surface.

Applying This Understanding

This knowledge shifts how we think about low-friction surfaces, moving from a static property to a dynamic process.

- If your primary focus is material science: The key insight is that Teflon's low friction is an active, sacrificial mechanism, not a passive surface quality.

- If your primary focus is engineering or design: You must account for the fact that a Teflon surface is designed to wear away over time as a fundamental part of its function.

Ultimately, Teflon's legendary slipperiness is a clever trick of physics where the material lubricates its own path.

Summary Table:

| Key Concept | Explanation |

|---|---|

| Core Mechanism | Material transfer creates a Teflon-on-Teflon sliding interface. |

| Key Insight | Slipperiness is a dynamic, sacrificial process, not a static surface property. |

| Real-World Implication | The surface wears down over time as part of its normal function. |

Need high-performance, low-friction PTFE (Teflon™) components?

Understanding the precise, sacrificial nature of PTFE is key to designing durable and effective components. At KINTEK, we specialize in manufacturing precision PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. We ensure your components are fabricated to the exact specifications required for optimal performance and longevity.

Let's discuss your project requirements: Contact our experts today for custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of using PTFE? Achieve Unmatched Performance in Extreme Environments

- When did the industrial production of PTFE begin? From Military Secret to Industrial Revolution

- What automotive application benefits from PTFE coating? Enhance Vehicle Reliability and Performance

- Why is PTFE's chemical inertness important for aerospace applications? Ensuring Safety & Reliability in Demanding Environments

- What temperature range can PTFE withstand? Master Its -200°C to 260°C Operating Window

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the limitations of PTFE? Understanding Creep, Abrasion, and Radiation Weaknesses

- How does the temperature range of RPTFE compare to other PTFE materials? Maximize Performance Under Load