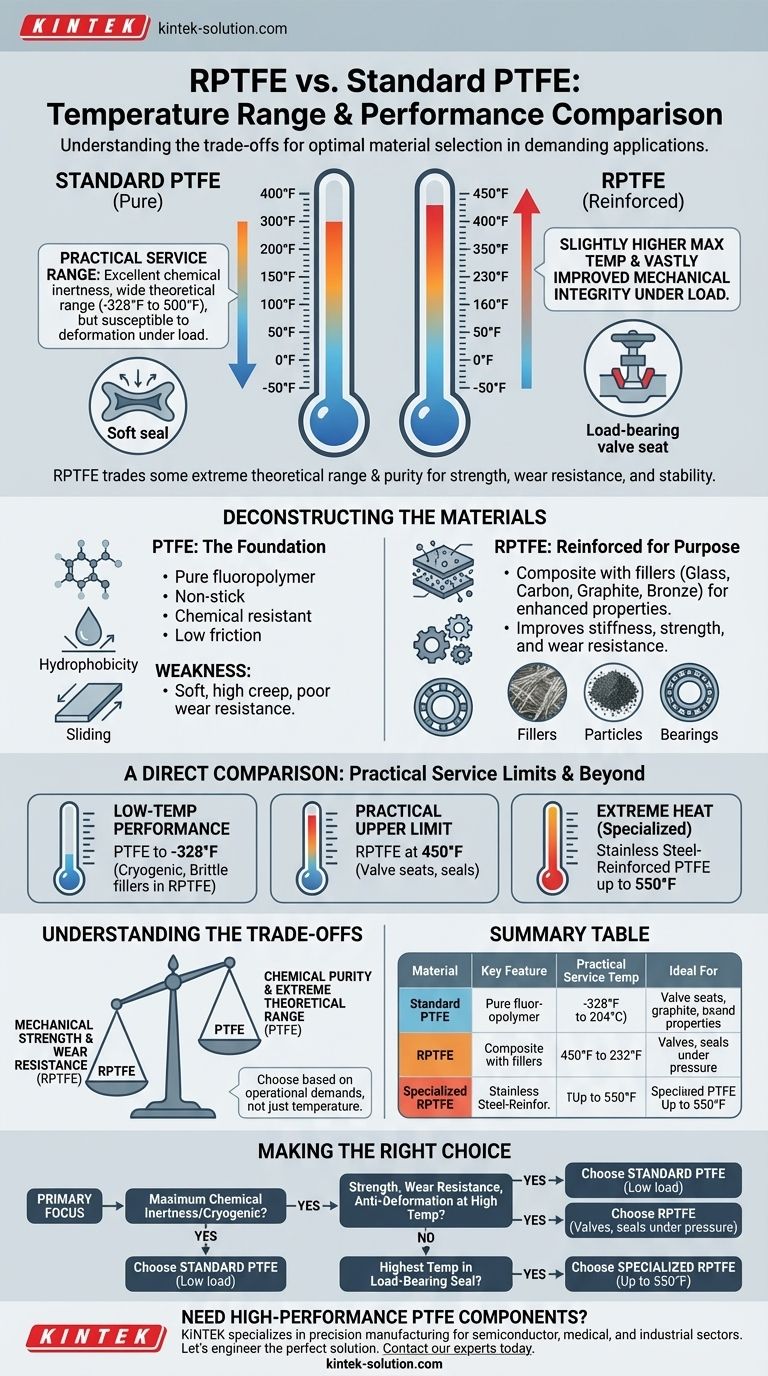

In direct comparisons for specific applications, Reinforced Polytetrafluoroethylene (RPTFE) offers a slightly higher maximum operating temperature than standard Polytetrafluoroethylene (PTFE). RPTFE is typically rated for a service range of -50°F to 450°F (-45°C to 232°C), while standard PTFE is often rated slightly lower at -50°F to 400°F (-45°C to 204°C) in similar mechanical uses. This modest increase, however, points to a much more significant distinction: RPTFE is engineered to maintain its mechanical integrity under load at these temperatures, a key weakness of pure PTFE.

Choosing between these materials is not a simple matter of checking a temperature chart. The core decision hinges on understanding that RPTFE trades some of pure PTFE's extreme theoretical temperature range and chemical purity for vastly improved mechanical strength, wear resistance, and stability under pressure.

Deconstructing PTFE: The Foundation Material

What is PTFE?

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer famous for its non-stick properties and is widely known by the brand name Teflon. It is a pure polymer consisting only of carbon and fluorine bonds.

This simple chemical structure gives PTFE its remarkable resistance to chemicals, its hydrophobic nature, and its exceptionally low coefficient of friction.

The Exceptional Temperature Range of Pure PTFE

In its pure, unfilled state, PTFE boasts one of the widest operating temperature ranges of any polymer. It can theoretically be used at temperatures from approximately -328°F (-200°C) up to 500°F (260°C).

This incredible range makes it suitable for extreme environments, from cryogenic applications in aerospace to high-heat industrial processes.

Key Weaknesses: Deformation and Wear

Despite its thermal stability, pure PTFE has significant mechanical limitations. It is a relatively soft material that is highly susceptible to "creep" or deformation, especially under load pressure and at elevated temperatures. It also has poor wear resistance.

Introducing RPTFE: Reinforcement for a Purpose

What is RPTFE?

RPTFE stands for Reinforced Polytetrafluoroethylene. It is not a pure polymer but a composite material where PTFE serves as the base matrix.

Fillers are added to the PTFE base to create a material with enhanced mechanical properties tailored for specific performance requirements.

Common Fillers and Their Impact

Various materials can be used to reinforce PTFE, with each one imparting different characteristics:

- Glass Fiber: Improves stiffness and wear resistance.

- Carbon: Increases compressive strength and hardness.

- Graphite: Reduces friction and improves wear properties.

- Bronze: Enhances strength and thermal conductivity.

These fillers fundamentally change the material's behavior, making it far more suitable for demanding mechanical parts like valve seats, seals, and bearings.

The Practical Temperature Range of RPTFE

The widely cited range of -50°F to 450°F for RPTFE represents its practical service temperature. This is the range in which the material maintains its structural integrity and reinforced properties under the mechanical stress it was designed for.

A Direct Comparison: Temperature and Beyond

Upper Temperature Limits

For components like valve seats, RPTFE's 450°F limit provides a tangible advantage over standard PTFE's 400°F limit. For even more extreme needs, materials like stainless steel-reinforced PTFE can push the upper limit to 550°F.

Low-Temperature Performance

This is a critical distinction. While RPTFE performs well down to -50°F, this is significantly less extreme than pure PTFE's potential in cryogenic applications reaching below -300°F. The fillers that provide strength can become brittle at these ultra-low temperatures.

Strength and Deformation Resistance

This is the primary reason for choosing RPTFE. It is vastly superior to pure PTFE in its ability to resist deforming or extruding under pressure, especially at the higher end of its temperature range.

Understanding the Trade-offs

Mechanical Strength vs. Chemical Purity

Adding fillers dramatically improves mechanical properties, but it can compromise PTFE's legendary chemical inertness. The filler material may not be as resistant to certain corrosive chemicals as pure PTFE is.

Practical Service Range vs. Theoretical Limits

It is crucial to distinguish between the theoretical temperature stability of pure PTFE and the practical operating range of a mechanical part. While pure PTFE remains stable at 500°F, it may be too soft to function as a reliable seal under pressure at that temperature. RPTFE is designed to work under those pressures.

The Impact of the Filler

The specific type of reinforcement dictates the final performance. A glass-filled RPTFE will have different thermal, chemical, and wear properties than a carbon-filled variant. The choice of filler must align with the specific demands of the application.

Making the Right Choice for Your Application

When selecting a material, consider the full scope of your operational demands, not just the temperature.

- If your primary focus is maximum chemical inertness and the widest possible temperature range (especially cryogenic): Pure, unfilled PTFE is the superior choice, provided the mechanical load is low.

- If your primary focus is strength, wear resistance, and preventing deformation under load at high temperatures: RPTFE is the definitive solution, offering a measurable boost in practical service temperature over standard PTFE.

- If your primary focus is the highest possible temperature performance in a load-bearing seal: A specialized material like stainless steel-reinforced PTFE may be necessary to reach service temperatures up to 550°F.

Ultimately, selecting the right material requires looking beyond a single temperature value to the mechanical and chemical demands of your specific environment.

Summary Table:

| Material | Key Feature | Practical Service Temperature | Ideal For |

|---|---|---|---|

| Standard PTFE | Maximum chemical inertness, wide theoretical range | -50°F to 400°F (-45°C to 204°C) | Low-load applications, extreme chemical exposure |

| RPTFE (Reinforced) | Superior mechanical strength, wear resistance | -50°F to 450°F (-45°C to 232°C) | Valves, seals, bearings under pressure and heat |

| Specialized RPTFE (e.g., Stainless Steel) | Highest temperature performance under load | Up to 550°F (288°C) | Extreme high-temperature, high-stress environments |

Need High-Performance PTFE Components for Your Application?

Choosing between standard PTFE and RPTFE is critical for the reliability of your components in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—tailored to your exact operational demands.

We help you navigate the trade-offs between temperature range, chemical resistance, and mechanical strength to ensure optimal performance. From prototypes to high-volume orders, our custom fabrication prioritizes precision and durability.

Let's engineer the perfect solution for your needs. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials