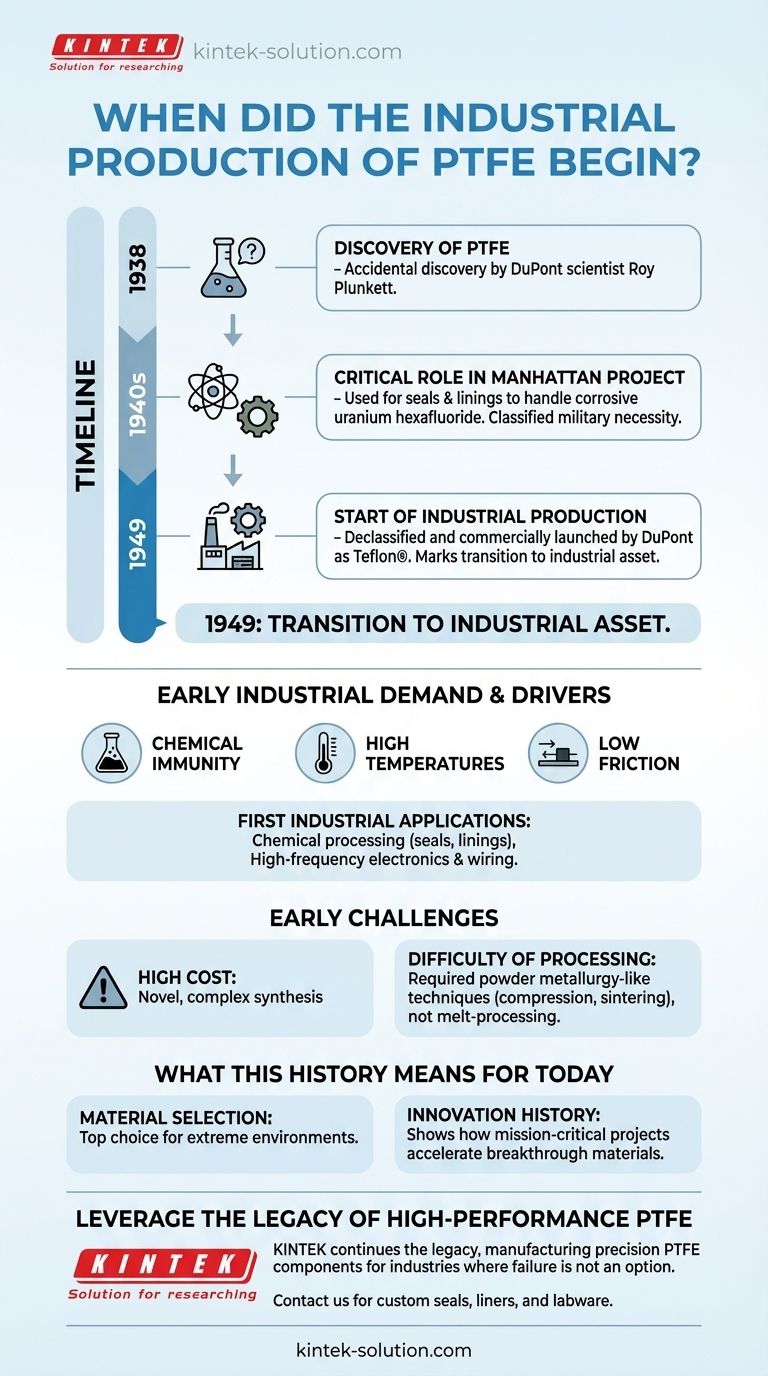

The industrial production of Polytetrafluoroethylene (PTFE) began in 1949, marking its transition from a classified, strategic material into a broader industrial asset. Although its commercial availability started then, PTFE's most critical early use occurred years earlier during the Manhattan Project, where its unique properties were essential for developing the atomic bomb.

While the year 1949 marks the beginning of its commercial life, PTFE's true origin story is one of military necessity. Its incredible chemical resistance made it the only viable solution for a critical national security challenge, years before it became available to other industries.

The Path from Secret Weapon to Industrial Staple

PTFE's journey to industrial production was not driven by typical market demand. It was a material born of specific, high-stakes technical challenges that demonstrated its immense value long before it was widely known.

A Critical Role in the Manhattan Project

During World War II, scientists working on the Manhattan Project faced a significant materials science problem. They needed to handle uranium hexafluoride, a highly corrosive gas used in the uranium enrichment process.

This substance was so aggressive it destroyed nearly every material it touched. PTFE, with its extreme chemical inertness, was one of the few materials that could withstand it.

It was used to coat gaskets, seals, and the linings of pipes and valves at the K-25 enrichment plant in Oak Ridge, Tennessee. This application was a closely guarded secret but proved the material's unparalleled performance in extreme chemical environments.

Declassification and Commercialization

Following the war, DuPont, the company that had discovered PTFE in 1938 and produced it for the government, was able to declassify the material. Seeing its potential, the company began scaling up for commercial and industrial sales.

This effort culminated in 1949, the year officially recognized for the start of industrial-scale production. The material was initially sold under the DuPont trade name Teflon.

Understanding the Early Industrial Demand

The shift to industrial production in 1949 was driven by the very properties that made PTFE invaluable to the war effort. Industries facing their own extreme challenges were eager to adopt this new "super-material."

Key Properties Driving Adoption

Early industrial users were not seeking a non-stick coating for pans; they were solving severe engineering problems. The primary drivers were PTFE's near-total chemical immunity, its performance at high temperatures, and its extremely low coefficient of friction.

First Industrial Applications

Initial uses were concentrated in demanding sectors. The chemical processing industry used PTFE for seals, gaskets, and vessel linings to handle corrosive acids and solvents. Its properties as an excellent electrical insulator also led to its use in high-frequency electronics and wiring.

Early Challenges and Trade-offs

Despite its remarkable properties, PTFE was not an easy material to work with, which limited its initial adoption.

High Cost

As a novel specialty polymer that was difficult to synthesize, PTFE was initially very expensive. Its use was justified only in high-value applications where no other material could perform the job.

Difficulty of Processing

Unlike common thermoplastics, PTFE cannot be melt-processed using conventional injection molding or extrusion. It must be processed using techniques more akin to powder metallurgy, such as compression and sintering (heating below its melting point until the particles fuse). This complexity added to the cost and created a barrier to entry for many potential users.

What This History Means for Today

Understanding the origin of PTFE provides critical context for its modern applications. Its history is not one of a simple consumer product, but of a high-performance problem-solver.

- If your primary focus is material selection: Remember that PTFE was created for the most extreme environments; it remains a top choice for applications involving aggressive chemicals, high temperatures, or critical electrical insulation.

- If your primary focus is innovation history: PTFE's journey from a secret military asset to an industrial workhorse shows how mission-critical government projects can accelerate the development and adoption of breakthrough materials.

Knowing a material's origin story allows you to fully appreciate its capabilities and apply it with purpose.

Summary Table:

| Key Milestone | Year | Significance |

|---|---|---|

| Discovery of PTFE | 1938 | Accidental discovery by DuPont scientist Roy Plunkett. |

| Critical Use in Manhattan Project | 1940s | Used for seals and linings to handle corrosive uranium hexafluoride. |

| Start of Industrial Production | 1949 | Declassified and commercially launched by DuPont under the Teflon® brand. |

Leverage the Legacy of High-Performance PTFE

PTFE was born to solve the most demanding material challenges. At KINTEK, we continue that legacy by manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where failure is not an option.

Are you facing extreme chemical, thermal, or electrical challenges? Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the right PTFE solution for your specific needs in the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEB today to discuss how our high-performance PTFE components can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of carbon graphite reinforced PTFE? Achieve Superior Wear & Creep Resistance

- What certifications does the manufacturer of PTFE products have? Ensure Quality with ISO 9001 Certification

- What are the key advantages of PTFE compared to other engineering plastics? Unmatched Chemical & Thermal Resistance

- What are the key components of PTFE? Unlocking the Power of Carbon and Fluorine

- What is PTFE and how was it first manufactured? The Accidental Discovery of Teflon

- What are the advantages of PTFE coating? Achieve Superior Low Friction & Chemical Resistance

- What family of substances does PTFE belong to? Understanding PFAS & Fluoropolymer Safety

- What is the scientific name for Teflon and what type of material is it? A Guide to PTFE