In short, PTFE's chemical inertness is critical in aerospace because it guarantees that components like seals, gaskets, and coatings will not degrade, fail, or contaminate sensitive systems when exposed to aggressive substances like jet fuel, hydraulic fluids, and de-icing agents. This property is a cornerstone of operational safety and long-term reliability in an environment where material failure is not an option.

In aerospace, component reliability is paramount. PTFE's chemical stability is not just a material benefit; it is a fundamental design principle that prevents catastrophic leaks and ensures parts function reliably over their entire service life, even under constant chemical and thermal stress.

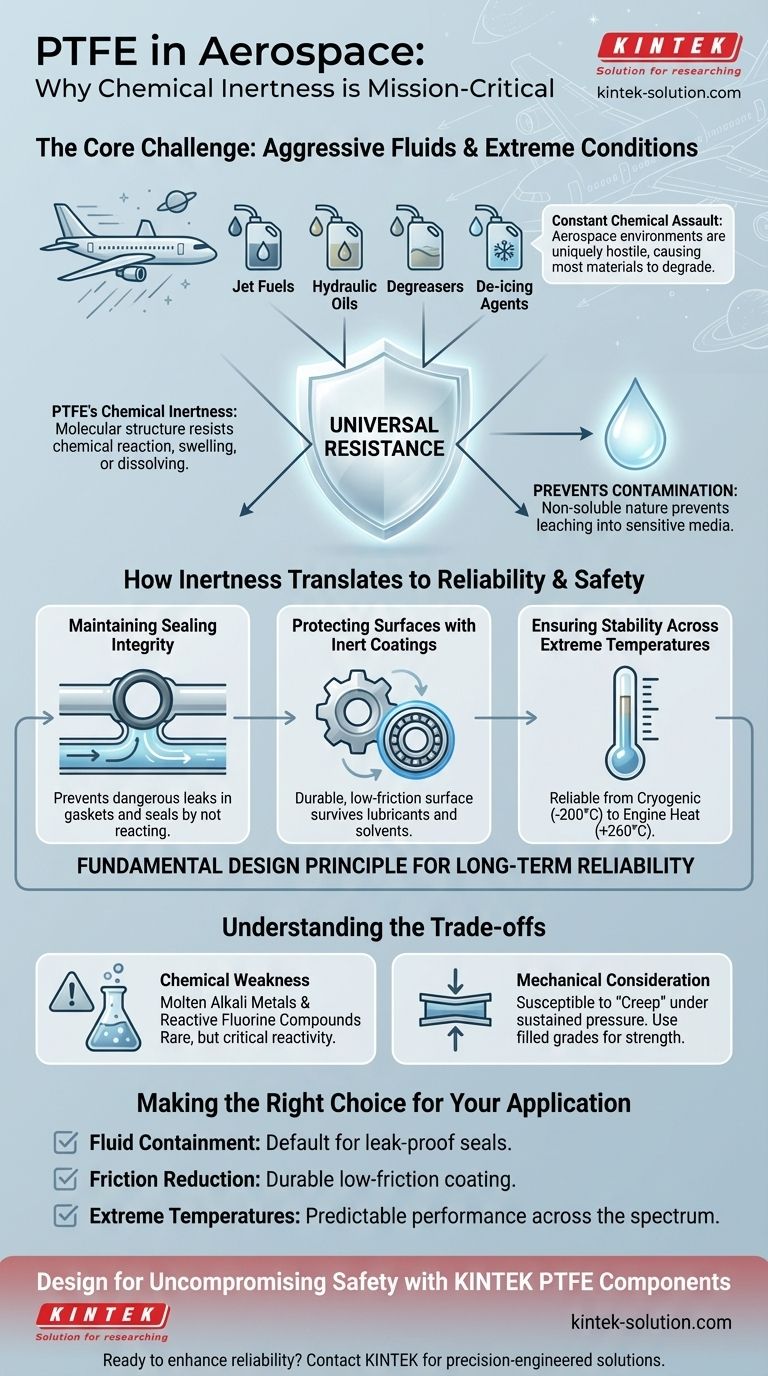

The Core Challenge: Aggressive Fluids and Extreme Conditions

Aerospace environments are uniquely hostile to materials. Components are constantly exposed to a cocktail of aggressive chemicals and radical temperature shifts, creating a scenario where most materials would quickly degrade.

The Constant Chemical Assault

Aircraft rely on a variety of chemically aggressive fluids to operate. These include hydrocarbon-based jet fuels, synthetic hydraulic oils, powerful degreasers, and corrosive de-icing agents.

A material used for seals or hoses in these systems must be able to withstand constant exposure without swelling, hardening, or dissolving. PTFE's molecular structure makes it almost universally resistant to these substances.

Preventing Contamination of Sensitive Media

The inertness of PTFE is a two-way street. Not only does it resist being attacked by fluids, but its non-soluble nature also ensures it does not leach particles or chemicals into the fluids.

This is vital for maintaining the purity of fuel and the precise chemical composition of hydraulic fluids, where even minor contamination can degrade performance or damage downstream components.

How Inertness Translates to Reliability and Safety

PTFE's chemical stability directly impacts the two most important factors in aerospace engineering: reliability and safety. It ensures that critical components perform their function without fail from takeoff to landing.

Maintaining Sealing Integrity

The most common application for PTFE is in gaskets, O-rings, and seals within fuel lines, hydraulic actuators, and engines.

If these seals were to react with the fluids they contain, they would quickly lose their sealing properties, leading to dangerous leaks. PTFE's inertness ensures a stable, reliable seal, preventing the loss of flammable fuel or high-pressure hydraulic fluid.

Protecting Surfaces with Inert Coatings

PTFE is also used as a low-friction coating on engine parts, gears, and bearings. These coatings must not only reduce wear but also survive contact with lubricants and cleaning solvents.

Its chemical resistance ensures the coating remains bonded and functional, protecting the underlying metal from both friction and corrosion over thousands of operational hours.

Ensuring Stability Across Extreme Temperatures

Aerospace applications involve a vast temperature range, from cryogenic levels in space or at high altitude (-200°C) to high temperatures near engines (+260°C).

PTFE's chemical inertness is maintained across this entire spectrum. Unlike other materials that can become reactive or brittle at temperature extremes, PTFE remains stable and reliable, ensuring consistent performance.

Understanding the Trade-offs

While its chemical properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to proper application.

Weakness to Specific Chemicals

PTFE’s primary chemical weakness is its reactivity with molten alkali metals (like sodium and potassium) and some rare, highly reactive fluorine compounds. While exposure is unlikely in most aerospace operations, it is a critical chemical limitation to be aware of for specialized applications.

Mechanical Property Considerations

PTFE is a relatively soft material and can be susceptible to "creep" or cold flow under sustained pressure, particularly at higher temperatures. In high-pressure sealing applications, this must be managed through proper gland design or by using filled grades of PTFE, which incorporate materials like glass or carbon to improve mechanical strength.

Making the Right Choice for Your Application

Your choice of material must align with the primary challenge you are trying to solve.

- If your primary focus is fluid containment in fuel or hydraulic systems: PTFE's unmatched chemical resistance makes it the default choice for seals and gaskets to ensure leak-proof, long-term safety.

- If your primary focus is reducing friction on moving parts: A PTFE coating provides a durable, low-friction surface that will not degrade when exposed to lubricants, solvents, or temperature swings.

- If your primary focus is reliability in extreme temperatures: PTFE's ability to remain chemically stable and mechanically functional from cryogenic lows to engine-level highs ensures predictable performance.

By leveraging PTFE's profound chemical resilience, you are fundamentally designing for safety, longevity, and reliability in the demanding aerospace environment.

Summary Table:

| Key Aspect | Why It Matters in Aerospace |

|---|---|

| Resists Aggressive Fluids | Withstands jet fuel, hydraulic oils, and de-icing agents without degrading. |

| Prevents System Contamination | Non-soluble nature ensures no particles leach into sensitive fuel or hydraulic systems. |

| Maintains Sealing Integrity | Prevents dangerous leaks in gaskets and seals by not reacting with contained fluids. |

| Stable Across Extreme Temperatures | Functions reliably from cryogenic (-200°C) to high heat (+260°C) without becoming reactive. |

| Limitation: Mechanical Creep | Can deform under sustained pressure; managed with filled grades or proper design. |

Design for Uncompromising Safety with KINTEK PTFE Components

When failure is not an option, your aerospace components demand the proven chemical inertness and reliability of PTFE. KINTEK specializes in manufacturing high-precision PTFE seals, liners, coatings, and custom labware for the semiconductor, medical, laboratory, and industrial sectors.

We help you mitigate risk and ensure long-term performance by providing components that withstand the harshest chemical and thermal environments. From custom prototypes to high-volume production, our expertise ensures your designs meet the highest standards of aerospace safety.

Ready to enhance your application's reliability? Contact KINTEK today to discuss your specific requirements and get a quote for precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the difference between virgin and modified PTFE? Choose the Right Material for Your Application

- What are the main material characteristics of PTFE? Unlock Superior Performance in Extreme Environments

- How is Teflon utilized in the electronics industry? Ensuring Signal Integrity and Reliability

- What factors can influence the hardness of PTFE? It's All About the Fillers

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application

- What are the different grades and variants of PTFE? Choose the Right Material for Your Application

- How is FEP Teflon different from other types in terms of properties? The Key is Fabrication Flexibility

- How do graphite fillers enhance PTFE? Achieve Superior Self-Lubrication and Wear Resistance