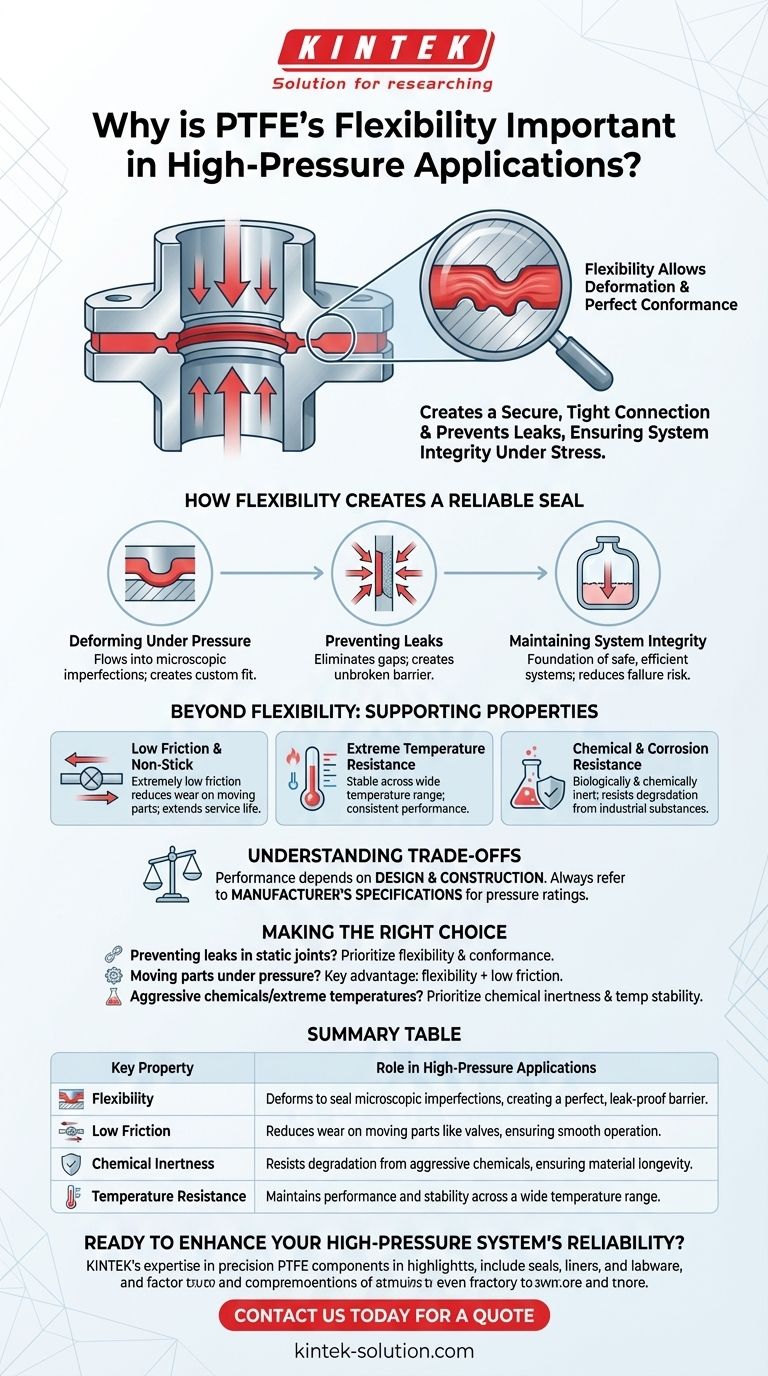

At its core, PTFE's flexibility is critical in high-pressure applications because it allows the material to deform and conform perfectly to the surfaces it is sealing. This creates a secure, tight connection between components like pipes or valve seats, effectively preventing leaks and ensuring the overall integrity of the system under stress.

While flexibility provides the immediate mechanical seal, PTFE's true value in high-pressure systems comes from its unique combination of properties—low friction, chemical inertness, and wide temperature tolerance—which work together to ensure long-term reliability.

How Flexibility Creates a Reliable Seal

The primary function of a seal or gasket in a high-pressure system is to block any potential path for fluid or gas to escape. PTFE's physical properties make it exceptionally well-suited for this task.

Deforming Under Pressure

When pressure is applied, PTFE has the ability to flow into microscopic imperfections on the surfaces of pipes, flanges, or valve bodies. This creates a custom, perfect fit that rigid materials cannot achieve.

Preventing Leaks

This perfect conformance eliminates the tiny gaps that are the source of leaks. By creating an unbroken barrier, PTFE maintains the pressure within the system and prevents the loss of valuable or hazardous materials.

Maintaining System Integrity

A reliable seal is the foundation of a safe and efficient high-pressure system. By preventing leaks, PTFE's flexibility directly contributes to the system's structural and operational integrity, reducing the risk of failure.

Beyond Flexibility: The Supporting Properties

While flexibility creates the seal, it's PTFE's other inherent characteristics that allow it to survive and perform reliably in demanding high-pressure environments.

Low Friction and Non-Stick Surface

In applications with moving parts, like valves or bearings, high pressure increases frictional forces. PTFE’s extremely low friction reduces the wear and tear on these components, ensuring smooth operation and extending their service life.

Extreme Temperature Resistance

High-pressure processes often generate significant heat or operate in extreme cold. PTFE's ability to remain stable and effective across a wide temperature range ensures the seal will not become brittle or degrade, providing consistent performance.

Chemical and Corrosion Resistance

High-pressure systems are frequently used to transport corrosive or aggressive chemicals. PTFE is biologically and chemically inert, meaning it resists degradation from virtually all industrial substances, ensuring the seal material itself does not become a point of failure.

Understanding the Trade-offs and Limitations

While highly effective, it is crucial to understand that PTFE is a material, not a universal solution. Its performance is always tied to the design of the component it is part of.

Not a Standalone Solution

The effectiveness of a PTFE seal or valve depends heavily on the design and construction of the specific part. A poorly designed valve will fail under pressure, regardless of the quality of the PTFE used.

Pressure Ratings Are Key

The maximum allowable pressure for any component is determined by its overall engineering. Always refer to the manufacturer’s specifications to ensure a particular PTFE part is suitable for the pressure demands of your specific application.

Making the Right Choice for Your Application

To leverage PTFE effectively, match its strengths to your primary operational goal.

- If your primary focus is preventing leaks in static joints: PTFE's flexibility and ability to conform to surfaces are the most critical properties for your evaluation.

- If your system involves moving parts under pressure (like valves or bearings): The combination of flexibility for sealing and extremely low friction for reducing wear is the key advantage.

- If your application involves aggressive chemicals or extreme temperatures: Prioritize PTFE for its unparalleled chemical inertness and wide temperature stability, which guarantee material longevity.

Ultimately, selecting PTFE for high-pressure use is an investment in system stability, where its unique properties work in concert to ensure reliability under stress.

Summary Table:

| Key Property | Role in High-Pressure Applications |

|---|---|

| Flexibility | Deforms to seal microscopic imperfections, creating a perfect, leak-proof barrier. |

| Low Friction | Reduces wear on moving parts like valves, ensuring smooth operation. |

| Chemical Inertness | Resists degradation from aggressive chemicals, ensuring material longevity. |

| Temperature Resistance | Maintains performance and stability across a wide temperature range. |

Ready to enhance your high-pressure system's reliability?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components are engineered to withstand extreme pressures, chemicals, and temperatures, guaranteeing system integrity and safety.

From prototypes to high-volume orders, we deliver solutions tailored to your specific challenges. Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications