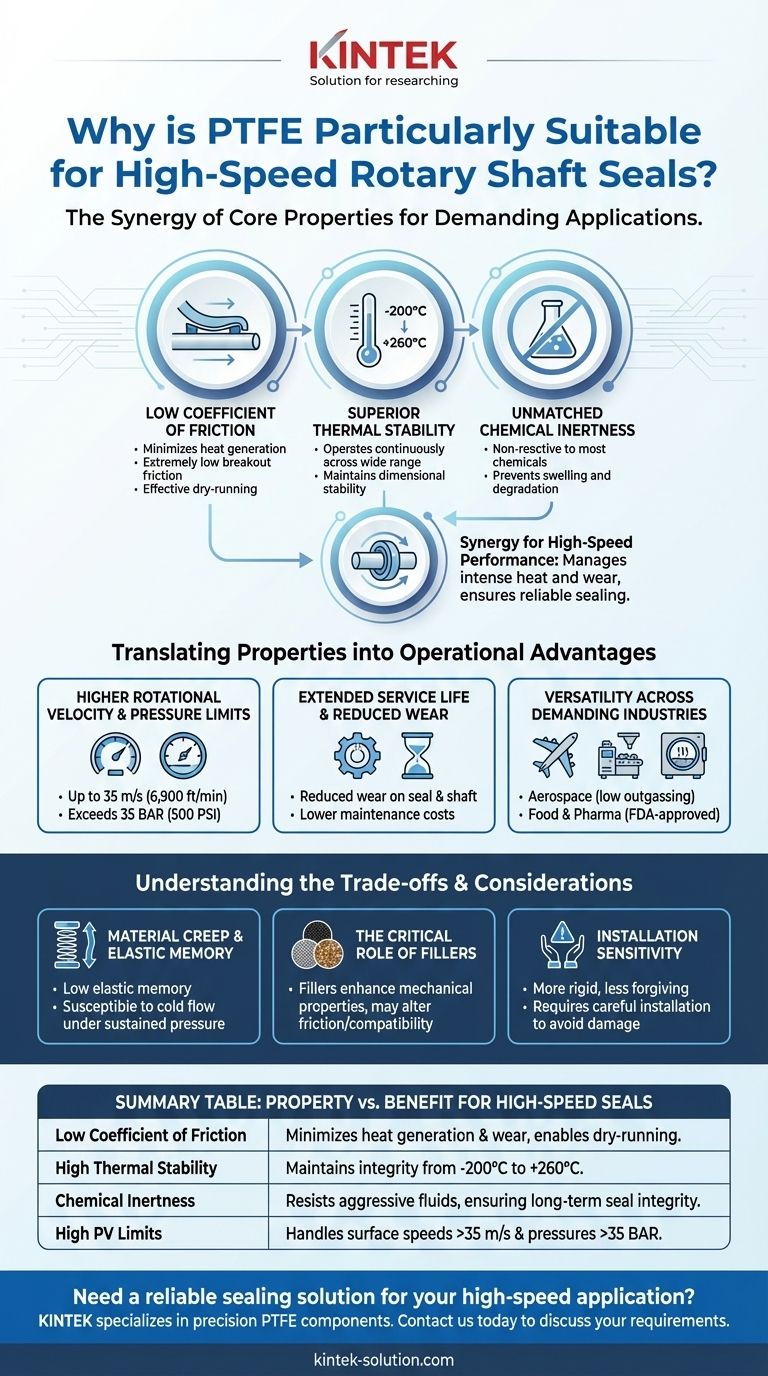

At its core, PTFE is exceptionally suitable for high-speed rotary shaft seals because of its unique combination of an extremely low coefficient of friction, high thermal stability, and chemical inertness. This trio of properties allows it to manage the intense heat and wear generated at high rotational speeds, conditions where traditional elastomeric seals would quickly degrade and fail.

The critical insight is not just one property, but the synergy between them. PTFE's self-lubricating nature minimizes heat generation, while its ability to withstand extreme temperatures ensures it remains stable and effective, providing a reliable seal in the most demanding high-velocity applications.

The Core Properties Enabling High-Speed Performance

To understand why PTFE excels, we must look at the fundamental material characteristics that directly address the challenges of high-speed rotation.

Exceptionally Low Coefficient of Friction

This is PTFE's most defining feature. A low friction coefficient means the seal glides over the shaft surface with minimal resistance.

This behavior directly reduces the frictional heat that is inevitably generated at high speeds, which is the primary cause of failure for many other seal materials.

It also results in extremely low "breakout" friction, preventing the jerky "stick-slip" motion that can occur at low speeds and cause premature wear. This self-lubricating quality allows for effective dry-running applications where external lubrication is impossible.

Superior Thermal Stability

Even with low friction, high velocities generate significant heat. PTFE is engineered to handle this thermal load.

It can operate continuously across an incredibly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This ensures the seal material remains dimensionally stable and does not harden, soften, or degrade, maintaining its sealing integrity even when the shaft and surrounding components heat up during operation.

Unmatched Chemical Inertness

High-speed applications often involve aggressive lubricants, coolants, or process fluids.

PTFE is non-reactive and inert to nearly all industrial chemicals and solvents.

This prevents the seal from swelling, shrinking, or breaking down upon exposure to these fluids, which would compromise its ability to maintain a tight seal.

Translating Properties into Operational Advantages

These material properties deliver tangible benefits in real-world machinery, leading to more robust and reliable performance.

Higher Rotational Velocity and Pressure Limits

The combination of low friction and thermal stability allows PTFE seals to operate at much higher surface velocities, often up to 35 m/s (6,900 ft/min).

They can also withstand significantly higher pressures than many elastomeric seals, frequently exceeding 35 BAR (500 PSI), making them suitable for high-performance hydraulic and pneumatic systems.

Extended Service Life and Reduced Wear

Because PTFE minimizes friction, it drastically reduces wear on both the seal lip and, critically, the expensive mating shaft.

This leads to a longer operational lifespan for the seal and less frequent need for shaft refinishing or replacement, lowering long-term maintenance costs.

Versatility Across Demanding Industries

PTFE's unique properties make it a solution for specialized fields. Its low outgassing is vital in aerospace and vacuum applications.

Furthermore, specific grades are FDA-approved, making them the material of choice for food, beverage, and pharmaceutical processing equipment where contamination is not an option.

Understanding the Trade-offs and Considerations

While highly capable, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Material Creep and Elastic Memory

Unlike rubber elastomers, PTFE has very little elastic memory. It does not "spring back" to its original shape as readily after being deformed.

Under high, sustained pressure and temperature, it can be susceptible to "cold flow" or creep, where the material slowly deforms over time. This can be a critical factor in high-pressure static sealing applications.

The Critical Role of Fillers

To counteract creep and improve wear resistance, virgin PTFE is often blended with fillers like carbon, glass fiber, or bronze.

These fillers enhance mechanical properties and thermal conductivity but can alter the material's friction coefficient and chemical compatibility. Selecting the right compound is crucial for optimizing performance.

Installation Sensitivity

The low elasticity of PTFE seals means they are more rigid and less forgiving than their rubber counterparts.

Care must be taken during installation to avoid scratching or nicking the seal lip, as even minor damage can create a leak path and lead to premature failure.

Making the Right Choice for Your Application

Selecting the right seal material depends entirely on the primary demands of your system.

- If your primary focus is maximum rotational speed and dry-running capability: PTFE's self-lubricating nature and thermal stability are unmatched by traditional elastomers.

- If your primary focus is operating in chemically aggressive environments: PTFE's near-universal chemical inertness ensures seal integrity where other materials would quickly degrade.

- If your primary focus is high pressure combined with high velocity: A filled PTFE compound provides the structural integrity and low-friction performance needed for this demanding quadrant.

- If your application requires significant elasticity to accommodate shaft imperfections: A high-performance elastomer might be a more suitable choice, provided the speed and temperature limits are respected.

By understanding these core principles, you can confidently specify PTFE seals for applications where performance and reliability are non-negotiable.

Summary Table:

| Property | Benefit for High-Speed Seals |

|---|---|

| Low Coefficient of Friction | Minimizes heat generation and wear, enables dry-running. |

| High Thermal Stability | Maintains integrity from -200°C to +260°C. |

| Chemical Inertness | Resists aggressive fluids, ensuring long-term seal integrity. |

| High PV Limits | Handles surface speeds >35 m/s and pressures >35 BAR. |

Need a reliable sealing solution for your high-speed application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a seal that delivers maximum performance, extended service life, and reduced maintenance costs.

Contact us today to discuss your specific requirements and let our experts provide a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the critical factors for proper PTFE gasket installation? Ensure a Leak-Free, Long-Lasting Seal

- Why are PTFE spring energized seals preferred in the oil and gas industry? Unmatched Resilience for HPHT & Corrosive Environments

- Are PTFE encapsulated O-rings compliant with industry standards? Ensure Purity & Performance in Critical Applications

- How are PTFE lip seals used in the aerospace industry? Ensure Reliability in Extreme Conditions

- Why choose PTFE V-Ring seals? Unmatched Reliability for Extreme Conditions

- What temperature can heat-resistant Teflon sheets withstand? Up to 500°F for Reliable Performance

- What are the key properties of PTFE balls? Unmatched Chemical Resistance and Non-Stick Performance

- How have PTFE coatings transformed the food processing industry? Boosting Efficiency, Safety & Profitability