For a successful PTFE gasket installation, the most critical factors are meticulous flange surface preparation, precise gasket alignment, and the application of correct, even bolt torque using a star or crisscross pattern. These steps are vital to leverage PTFE's sealing capabilities while preventing common failure modes like cold flow and extrusion.

A gasket failure is rarely a failure of the gasket itself, but rather a failure of the installation process. Achieving a reliable, long-lasting seal with PTFE isn't about brute force; it's a systematic procedure where controlled compression and surface integrity are the keys to success.

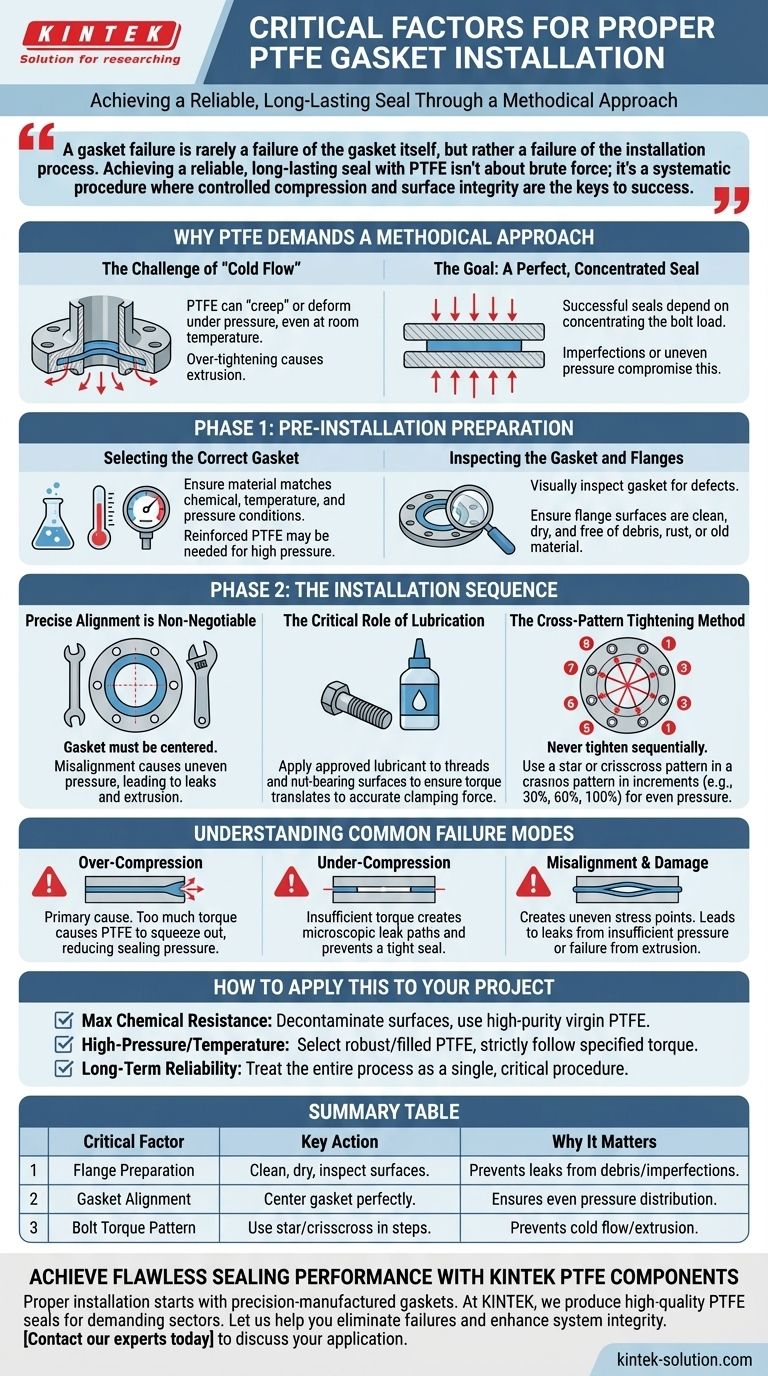

Why PTFE Demands a Methodical Approach

Polytetrafluoroethylene (PTFE) is a superior sealing material due to its chemical inertness and wide temperature range. However, its unique mechanical properties require a precise installation process to prevent failure.

The Challenge of "Cold Flow"

PTFE is a soft material that can "creep" or cold flow under pressure, even at room temperature. This means it will deform and squeeze out of the flange if excessive or uneven force is applied.

Proper installation aims to apply just enough compressive force to create a seal without causing the material to extrude from the joint.

The Goal: A Perfect, Concentrated Seal

A successful seal depends on concentrating the bolt load (clamping force) onto the gasket surface area. Any imperfections, misalignment, or uneven pressure will compromise this force concentration and create a potential leak path.

Phase 1: Pre-Installation Preparation

The most common installation failures begin before a single bolt is ever tightened. Rigorous preparation is the foundation of a reliable seal.

Selecting the Correct Gasket

Your first step is ensuring the gasket material matches the application. Consider the chemical compatibility, operating temperature range, and pressure conditions. For high-pressure service, a reinforced or modified PTFE may be necessary.

Inspecting the Gasket and Flanges

Before installation, visually inspect the gasket for any nicks, scratches, or defects. Handle it with care to avoid damage.

Crucially, inspect the flange sealing surfaces. They must be clean, dry, and free of any debris, rust, or old gasket material. Check for burrs or scratches on the raised surface that could compromise the seal.

Phase 2: The Installation Sequence

With proper preparation complete, the installation itself becomes a sequence of controlled, deliberate steps.

Precise Alignment is Non-Negotiable

The gasket must be perfectly centered on the flange face. A misaligned gasket will have uneven pressure applied to it, creating a high probability of both a leak on one side and extrusion on the other.

Use alignment tools if necessary to ensure the gasket is positioned correctly before bringing the flanges together.

The Critical Role of Lubrication

If recommended by the manufacturer, apply a small amount of an approved lubricant to the bolt threads and nut-bearing surfaces. This reduces friction and ensures the applied torque translates into an accurate and even clamping force on the gasket.

The Cross-Pattern Tightening Method

Never tighten bolts sequentially around the flange. Always use a star or crisscross pattern. This technique ensures the clamping force is applied evenly across the gasket surface, preventing pinching or localized over-compression.

Tighten the bolts in increments—for example, to 30% of the final torque, then 60%, and finally to 100%—still following the cross pattern for each round.

Understanding Common Failure Modes

Understanding how installations go wrong is key to getting them right. Almost all failures can be traced back to a small number of preventable errors.

Over-Compression: The Primary Cause of Failure

This is the most common mistake. Applying too much torque causes the soft PTFE material to extrude, or squeeze out of the flange. This not only ruins the gasket but also dramatically reduces the sealing pressure, leading to an almost certain leak.

Under-Compression: The Risk of an Inadequate Seal

Insufficient torque means there is not enough clamping force to make the gasket conform to the flange surfaces. This leaves microscopic leak paths and prevents the formation of a tight, reliable seal from the start.

Misalignment and Damage: Creating Inevitable Leaks

Inserting the gasket carelessly, allowing it to be pinched, or failing to center it properly creates uneven stress points. These areas will either leak due to insufficient pressure or fail due to extrusion, undermining the entire joint.

How to Apply This to Your Project

Your installation strategy should be guided by the specific demands of your system.

- If your primary focus is maximum chemical resistance: Ensure flange surfaces are completely decontaminated and you use a high-purity virgin PTFE gasket.

- If your primary focus is high-pressure or high-temperature service: Select a mechanically robust, filled or expanded PTFE and strictly follow the manufacturer's specified torque values to prevent extrusion.

- If your primary focus is long-term reliability and safety: Treat the entire process—from surface cleaning to final torque—as a single, critical procedure where every step is vital for success.

By treating gasket installation as a precise technical procedure, you transform a potential point of failure into a source of system integrity and safety.

Summary Table:

| Critical Factor | Key Action | Why It Matters |

|---|---|---|

| Flange Preparation | Clean, dry, and inspect surfaces for damage. | Prevents leaks from debris or imperfections. |

| Gasket Alignment | Center the gasket perfectly on the flange face. | Ensures even pressure distribution. |

| Bolt Torque Pattern | Use a star/crisscross pattern in incremental steps. | Prevents cold flow and extrusion from uneven force. |

Achieve Flawless Sealing Performance with KINTEK PTFE Components

Proper installation is only half the equation—it starts with a precision-manufactured gasket. At KINTEK, we specialize in producing high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need standard parts or custom fabrication from prototypes to high-volume orders, our focus on precision ensures your gaskets perform reliably under demanding conditions.

Let us help you eliminate installation failures and enhance system integrity.

Contact our experts today to discuss your specific application and receive tailored solutions that guarantee a perfect seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is a Teflon O-ring and what is its primary function? A Guide to Superior Sealing

- What aerospace applications use PTFE lip seals? Critical Sealing Solutions for Extreme Performance

- What are some specialized Teflon bearing products? A Guide to Material Systems and Forms

- What are PTFE/PFA lined ball valves designed for? Corrosion-Proof Flow Control for Aggressive Fluids

- What are the best applications for expanded PTFE (ePTFE) gaskets? Solve Sealing Challenges with Low Force

- How do fillers enhance the properties of modified PTFE gaskets? Improve Strength, Wear, and Creep Resistance

- What are the main applications of rotary shaft seals? From Automotive to Pharma, Ensure Zero Leaks

- What advantages do 40% bronze-filled PTFE bushings provide? Boost Load Capacity, Wear Resistance & Heat Dissipation