In short, PTFE spring energized seals are preferred in the oil and gas industry because of their unparalleled resilience. They provide a unique combination of extreme temperature and pressure resistance, near-universal chemical compatibility, and mechanical durability that standard elastomeric seals cannot match in such demanding conditions.

The core challenge in oil and gas is managing operational risk in environments that are simultaneously high-pressure, high-temperature, and chemically corrosive. PTFE spring energized seals solve this by providing a reliable, long-lasting sealing solution that resists degradation and prevents catastrophic leaks where other materials would fail.

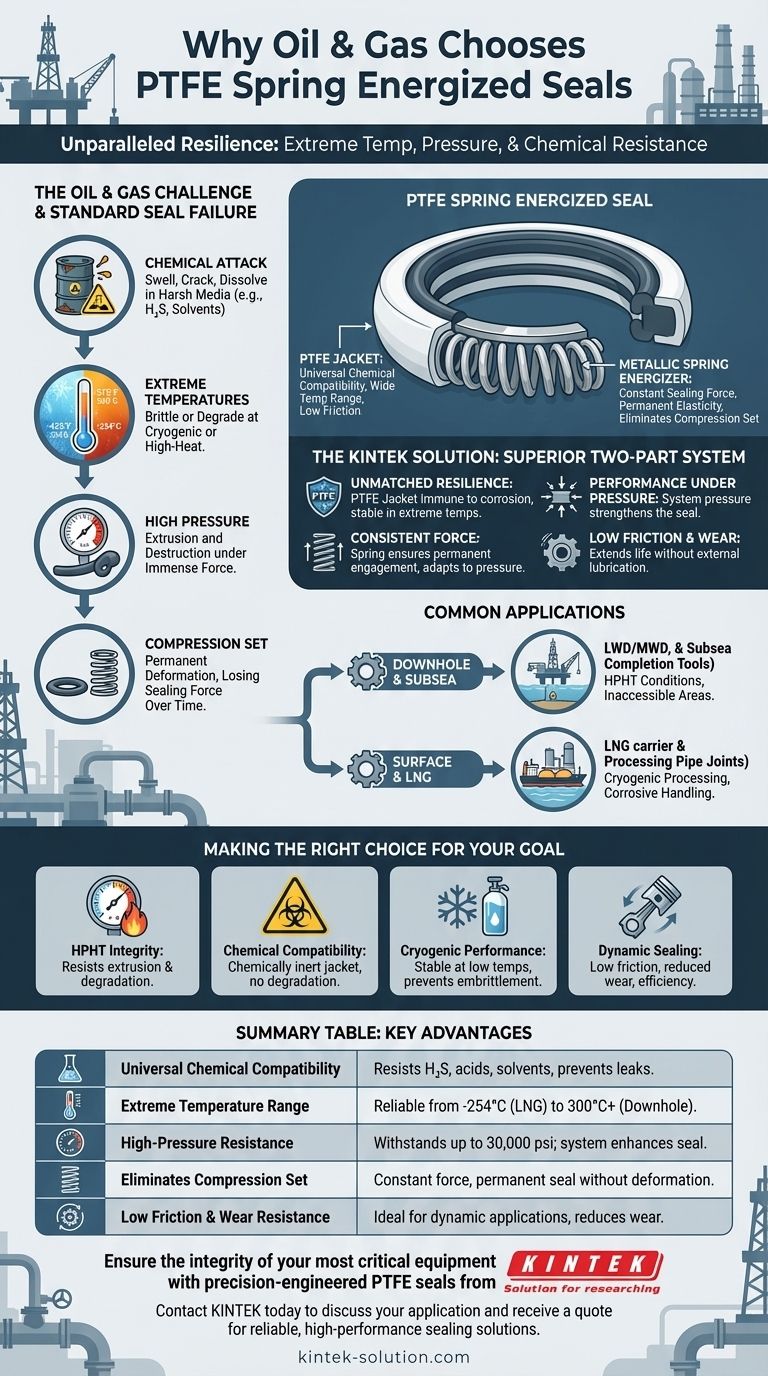

Why Standard Seals Fail in Oil & Gas

To understand the value of PTFE spring energized seals, we must first recognize the extreme conditions that cause conventional seals, like rubber O-rings, to break down.

The Problem of Chemical Attack

The oil and gas industry frequently deals with chemically aggressive media, including sour gas (H₂S), acid gas, steam, and various industrial solvents. These substances can cause standard elastomeric seals to swell, crack, or dissolve over time, leading to seal failure.

The Challenge of Extreme Temperatures

Operations range from cryogenic temperatures for Liquefied Natural Gas (LNG) equipment (down to -425°F / -254°C) to the extreme heat of downhole drilling tools (over 575°F / 300°C). Most materials become brittle at low temperatures or degrade rapidly at high temperatures, compromising their sealing ability.

The Impact of High Pressure

Equipment on oil rigs, in subsea systems, and in downhole tools operates under immense pressure, often ranging from 5,000 to 30,000 psi. This extreme force can physically extrude or destroy softer seal materials.

The Limitation of Compression Set

Standard seals rely on their inherent elasticity to create a seal. Over time, under constant pressure and temperature, they lose this elasticity and become permanently deformed—a phenomenon known as compression set. A seal with compression set no longer pushes back against the mating surfaces, creating a leak path.

The Unique Advantages of a Two-Part System

A PTFE spring energized seal is a two-component system: a precision-machined PTFE jacket and a metallic spring energizer. This design directly counters the challenges of the oil and gas environment.

Unmatched Material Resilience (The PTFE Jacket)

The seal's outer jacket is made from Polytetrafluoroethylene (PTFE), a fluoropolymer known for its exceptional properties. It offers universal chemical compatibility, making it virtually immune to degradation from corrosive fluids. Its wide service temperature range ensures it remains stable in both cryogenic and high-heat applications.

Consistent Sealing Force (The Energizer Spring)

The internal spring provides a constant, uniform load against the sealing surfaces. This permanent elasticity is the key difference from a standard O-ring. The spring ensures the seal remains engaged even with wear, temperature fluctuations, or pressure changes, and it completely eliminates the risk of compression set and aging embrittlement.

Superior Performance Under Pressure

The design of a spring energized seal cleverly uses system pressure to its advantage. High pressure pushes against the seal, forcing the PTFE jacket more tightly against the hardware and strengthening the seal's integrity precisely when it's needed most.

Low Friction and Wear Resistance

PTFE has an extremely low coefficient of friction, which is critical for dynamic applications in pumps, valves, and drilling tools. This property reduces wear and heat generation, extending the service life of both the seal and the equipment without requiring external lubrication.

Common Applications in the Field

The reliability of these seals makes them critical components across the industry.

Downhole and Subsea Equipment

Inaccessible and high-stakes tools used for drilling (LWD/MWD), completion, and subsea processing rely on these seals to prevent leaks in HPHT (High-Pressure, High-Temperature) conditions.

Surface and LNG Equipment

On the surface, PTFE seals are used in valves, pumps, and pipe expansion joints that handle corrosive materials and temperature fluctuations, particularly in LNG processing and transport where cryogenic performance is essential.

Making the Right Choice for Your Goal

The selection of a seal is driven by the specific demands of its application.

- If your primary focus is High-Pressure, High-Temperature (HPHT) integrity: The seal's ability to resist extrusion and material degradation under extreme heat and pressure is its most critical feature.

- If your primary focus is chemical compatibility with sour gas or harsh fluids: The chemically inert PTFE jacket ensures the seal will not degrade, providing long-term safety and reliability.

- If your primary focus is cryogenic performance for LNG: The material's stability at extremely low temperatures prevents embrittlement and leakage where other materials would fail.

- If your primary focus is dynamic sealing with low friction: The inherent properties of PTFE reduce wear and improve the efficiency and lifespan of moving components.

Ultimately, selecting a PTFE spring energized seal is a strategic engineering decision to ensure operational integrity in the world's most demanding industrial environments.

Summary Table:

| Key Advantage | Why It Matters in Oil & Gas |

|---|---|

| Universal Chemical Compatibility | Resists degradation from sour gas, acids, and solvents, preventing leaks. |

| Extreme Temperature Range | Performs reliably from cryogenic LNG (-254°C) to high-heat downhole (300°C+) applications. |

| High-Pressure Resistance | Withstands pressures up to 30,000 psi; system pressure enhances the seal. |

| Eliminates Compression Set | Spring energizer provides constant force, ensuring a permanent seal without deformation. |

| Low Friction & Wear Resistance | Ideal for dynamic applications in valves and pumps, reducing wear without lubrication. |

Ensure the integrity of your most critical equipment with precision-engineered PTFE seals from KINTEK.

Our seals are manufactured to meet the extreme demands of the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your specific HPHT, chemical, or cryogenic challenges.

Contact KINTEK today to discuss your application and receive a quote for reliable, high-performance sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability