Polytetrafluoroethylene (PTFE) is famous for its non-stick properties because of its unique molecular structure. Its backbone of carbon atoms is completely encased by a tight, dense shield of fluorine atoms. These carbon-fluorine bonds are exceptionally strong and stable, creating a very low-energy, chemically inert surface that other substances find nearly impossible to adhere to.

The non-stick quality of PTFE is not a superficial treatment; it is a fundamental property of its molecular architecture. The tightly bound fluorine atoms create a protective, low-energy shield that repels other molecules, resulting in one of the lowest coefficients of friction of any known solid.

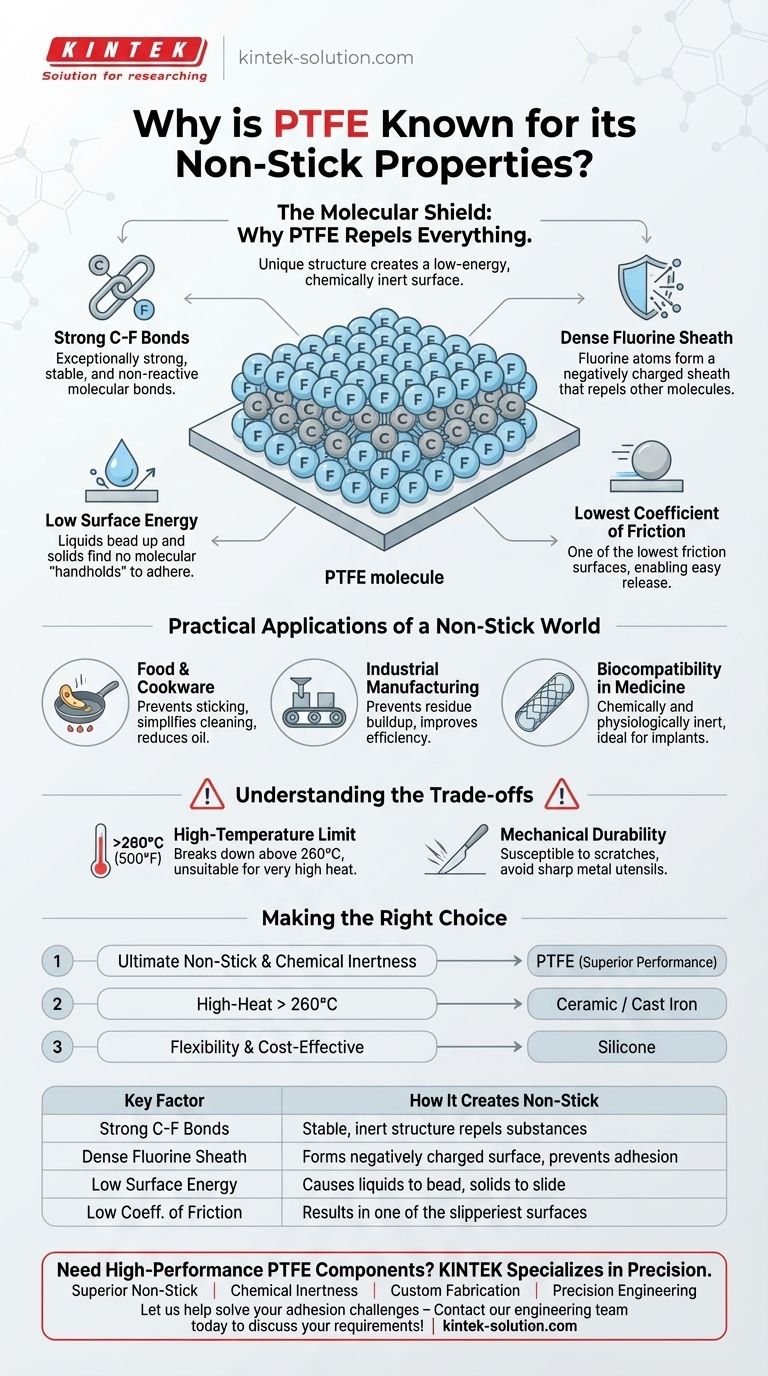

The Molecular Shield: Why PTFE Repels Everything

PTFE's non-stick behavior is a direct result of its chemical composition and the powerful forces at play on a microscopic level.

The Unbreakable Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest known in organic chemistry. This incredible strength means the fluorine atoms are held very tightly to the carbon chain, creating a molecule that is exceptionally stable and non-reactive.

A Surface of Pure Repulsion

Fluorine is the most electronegative element, meaning it has an extremely strong attraction for electrons. The fluorine atoms in PTFE pull the molecule's electrons so close that they form a dense, negatively charged sheath around the carbon backbone. This sheath effectively repels almost all other molecules, preventing them from getting close enough to stick.

Low Surface Energy in Practice

This molecular repulsion results in an extremely low surface energy. On a PTFE surface, liquids bead up and roll off instead of "wetting" the surface. For solids, there are virtually no molecular "handholds" to grab onto, which is why it feels so slippery to the touch.

The Lowest Coefficient of Friction

The practical outcome of this low-energy, repellent surface is an exceptionally low coefficient of friction. This physical property is what we perceive as "non-stick"—the inability of other materials to cling or bind to the PTFE.

Practical Applications of a Non-Stick World

The unique properties of PTFE make it invaluable across a wide range of industries where preventing adhesion is critical.

The Food and Cookware Industry

This is the most well-known application. PTFE coatings on cookware, bakeware, and food processing equipment prevent food from sticking, which simplifies cleaning, reduces the need for oils, and minimizes waste.

Industrial Manufacturing and Packaging

In industrial settings, PTFE coatings on machinery prevent residue, glues, or products from building up on rollers, molds, and conveyor belts. This improves operational efficiency and reduces downtime for cleaning.

Biocompatibility in Medicine

Because PTFE is so chemically inert, it is also physiologically inert. The human body does not recognize it as a foreign substance, preventing adverse reactions. This makes it an ideal material for medical applications like surgical grafts, implants, and artificial blood vessels.

Understanding the Trade-offs and Limitations

While its non-stick properties are unmatched, PTFE is not the perfect solution for every scenario. Understanding its limitations is key to using it effectively.

High-Temperature Sensitivity

PTFE is stable up to approximately 260°C (500°F). Above this temperature, the material can begin to break down and release fumes. This makes it unsuitable for very high-heat applications where materials like ceramic or cast iron excel.

Mechanical Durability

While chemically robust, PTFE coatings can be mechanically soft. They are susceptible to scratches and abrasions from sharp metal utensils, which can compromise the non-stick surface over time.

Comparison with Alternatives

Compared to modern ceramic coatings, PTFE is generally more durable and chemically resistant, but it cannot handle the same high temperatures. Compared to silicone, PTFE offers far superior non-stick performance and higher heat stability, though silicone provides greater flexibility.

Making the Right Choice for Your Goal

Selecting the correct material requires aligning its properties with your primary objective.

- If your primary focus is the ultimate non-stick performance and chemical inertness: PTFE remains the superior choice, especially for cookware, chemical processing, and medical devices.

- If your primary focus is high-heat applications above 260°C (500°F): You should immediately consider alternatives like ceramic-coated or uncoated cast iron.

- If your primary focus is flexibility for bakeware or seals: Silicone is often a more suitable and cost-effective material, provided its lower temperature limits are acceptable.

Understanding the molecular basis of PTFE's properties empowers you to move beyond simple labels and select the precise material your project demands.

Summary Table:

| Key Factor | How It Creates Non-Stick Properties |

|---|---|

| Strong Carbon-Fluorine Bonds | Creates a stable, chemically inert molecular structure that repels other substances |

| Dense Fluorine Sheath | Forms a negatively charged surface that prevents molecular adhesion |

| Extremely Low Surface Energy | Causes liquids to bead up and solids to slide off easily |

| Low Coefficient of Friction | Results in one of the slipperiest surfaces known to science |

Need High-Performance PTFE Components for Your Application?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) that leverage these exceptional non-stick properties for demanding applications.

Why Choose KINTEK PTFE?

- Superior Non-Stick Performance: Our PTFE components prevent material buildup and ensure easy cleaning

- Chemical Inertness: Ideal for semiconductor, medical, laboratory, and industrial environments

- Custom Fabrication: From prototypes to high-volume production runs

- Precision Engineering: Consistent quality for reliable performance

Let us help you solve your adhesion challenges – Contact our engineering team today to discuss your specific PTFE component requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions