In short, PTFE is critical to the chemical and steel industries because of its two defining properties: extreme chemical inertness and high-temperature stability. This unique combination allows it to survive and perform reliably in hostile environments where virtually all other polymers and many metals would rapidly corrode and fail, ensuring operational safety and continuity.

The decision to use Polytetrafluoroethylene (PTFE) is not merely a material choice; it is a strategic investment in operational reliability. By resisting chemical attack and thermal degradation, PTFE directly enhances plant safety, reduces costly downtime, and improves long-term cost-effectiveness.

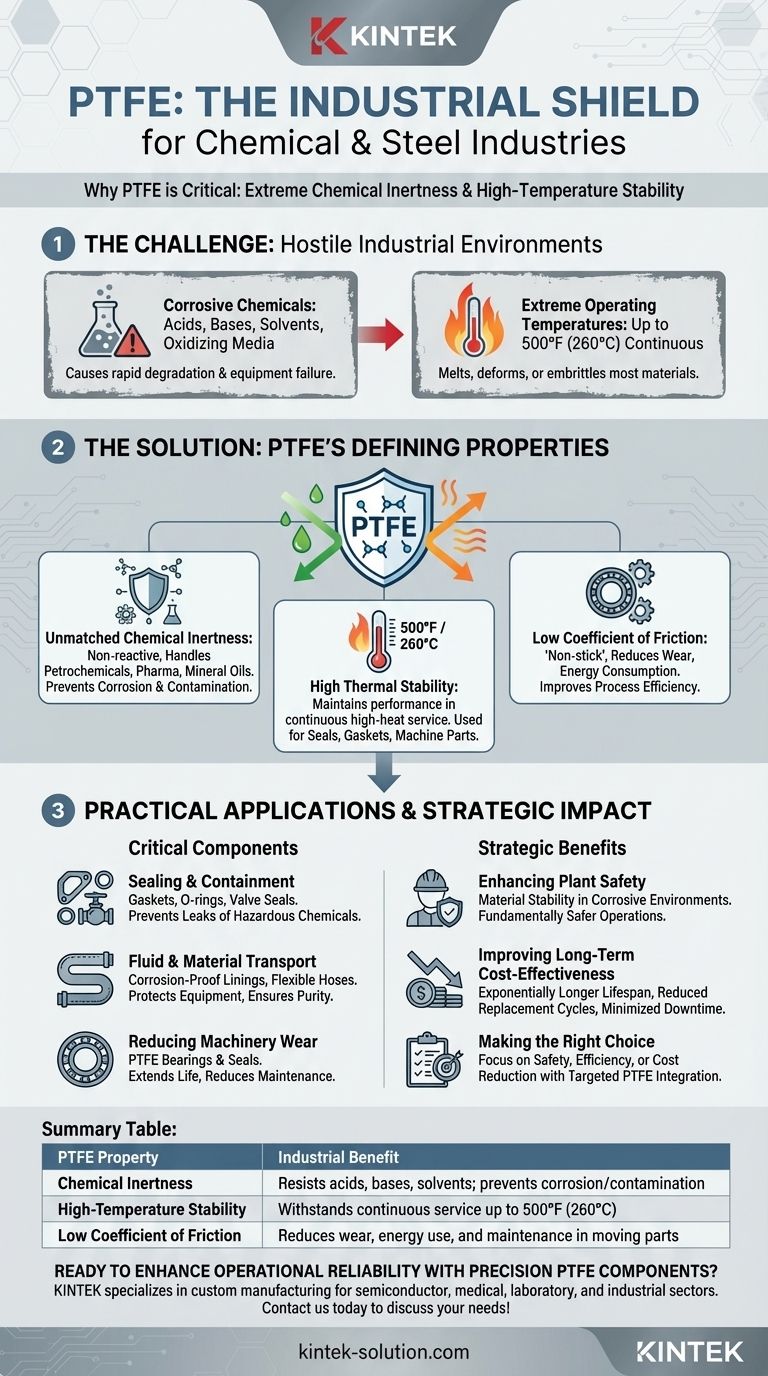

The Core Challenge: Hostile Industrial Environments

The chemical and steel industries present some of the most demanding conditions for any material. Equipment must consistently operate while exposed to a combination of aggressive factors that cause rapid deterioration.

Exposure to Corrosive Chemicals

Chemical processing involves a vast range of highly reactive substances, from strong acids and bases to aggressive solvents and oxidizing media. These materials will actively degrade most plastics and metals, leading to equipment failure.

Extreme Operating Temperatures

Both chemical reactions and steel manufacturing generate immense heat. Components must maintain their structural integrity and performance characteristics at temperatures that would cause other materials to melt, deform, or become brittle.

How PTFE's Properties Solve the Problem

PTFE's value comes from a unique set of properties that directly counter the challenges of these harsh environments. It functions where other materials simply cannot.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It can handle everything from petrochemicals and solvents to pharmaceuticals and mineral oils without degrading or contaminating the product.

This inertness is essential for lining reactors, hoses, and pipes, protecting the primary structure (often steel) from the corrosive contents it transports.

High Thermal Stability

PTFE maintains its properties across a wide temperature range, remaining stable and functional in continuous service up to 500°F (260°C).

This allows it to be used for seals, gaskets, and machine parts in high-heat processes where less stable polymers would fail catastrophically.

Low Coefficient of Friction

Often recognized for its "non-stick" quality in cookware, PTFE's low friction is a major industrial advantage. In bearings, seals, and other moving parts, it dramatically reduces wear and energy consumption.

This property also ensures smoother flow of viscous materials through hoses and pipes, improving process efficiency.

From Properties to Practical Applications

These core properties translate directly into a range of critical components that are fundamental to plant operations.

Sealing and Containment

The most common use for PTFE is in sealing materials like gaskets, O-rings, and valve seals. These are often the weakest points in a system.

Using PTFE in these critical spots prevents leaks of hazardous chemicals, which is fundamental to preventing unforeseen accidents and ensuring overall plant reliability.

Fluid and Material Transport

PTFE is used to create corrosion-proof linings for steel pipes and reaction vessels. It is also the primary material for flexible hoses that transfer aggressive chemicals.

This application protects expensive capital equipment from damage and ensures the purity of the product being processed.

Reducing Machinery Wear

In machinery with moving parts, PTFE bearings and seals reduce friction and prevent premature failure. This extends the life of the equipment and significantly reduces maintenance schedules and associated downtime.

Understanding the Strategic Impact

Choosing PTFE is about more than just technical specifications; it has a direct impact on the safety, reliability,and financial performance of an operation.

Enhancing Plant Safety

Material failure in a chemical or steel plant can have catastrophic consequences. By using a material that will not degrade when exposed to corrosive agents or heat, you are fundamentally investing in a safer operating environment.

Improving Long-Term Cost-Effectiveness

While PTFE components may have a higher initial cost than some alternatives, their lifespan is exponentially longer in harsh conditions.

The savings come from drastically reduced replacement cycles, minimized process downtime for maintenance, and the prevention of costly failures. This makes its total cost of ownership very low.

Acknowledging the Limitations

PTFE is not a structural material. It has relatively low mechanical strength compared to metals and is not suitable for high-load-bearing applications on its own. Its value is as a liner, a seal, or a low-friction component, often integrated with stronger materials like steel.

Making the Right Choice for Your Application

You should specify PTFE based on the primary goal you need to achieve in a specific application.

- If your primary focus is safety and reliability: Use PTFE for all critical seals, gaskets, and linings that are exposed to corrosive materials, as this is your best defense against leaks and failure.

- If your primary focus is operational efficiency: Employ PTFE-lined hoses and pipes to ensure smooth, uncontaminated material flow and use PTFE bearings to reduce friction and maintenance on machinery.

- If your primary focus is long-term cost reduction: Invest in PTFE for components in harsh service to drastically lower the frequency of replacement and minimize costly production downtime.

Ultimately, integrating PTFE is a proactive measure to fortify your operations against their most demanding challenges.

Summary Table:

| PTFE Property | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents corrosion and contamination |

| High-Temperature Stability | Withstands continuous service up to 500°F (260°C) |

| Low Coefficient of Friction | Reduces wear, energy use, and maintenance in moving parts |

Ready to enhance your operational reliability with precision PTFE components? KINTEK specializes in custom manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production—from prototypes to high-volume orders—ensures you get components that withstand harsh conditions, improve safety, and reduce downtime. Contact us today to discuss your specific needs and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry