At its core, PTFE is ideal for high-purity applications because of its extreme chemical inertness and physically non-contaminating surface. As a fluoropolymer, Polytetrafluoroethylene (PTFE) possesses an incredibly strong carbon-fluorine bond, making it non-reactive to nearly all chemicals. This inherent stability, combined with its smooth, non-stick surface, ensures that the material itself will not add, remove, or react with the sensitive media it contains.

The true value of PTFE in high-purity systems is its role as a completely neutral boundary. It does not simply resist contamination; its fundamental properties ensure it does not become a source of contamination, preserving the absolute integrity of the process.

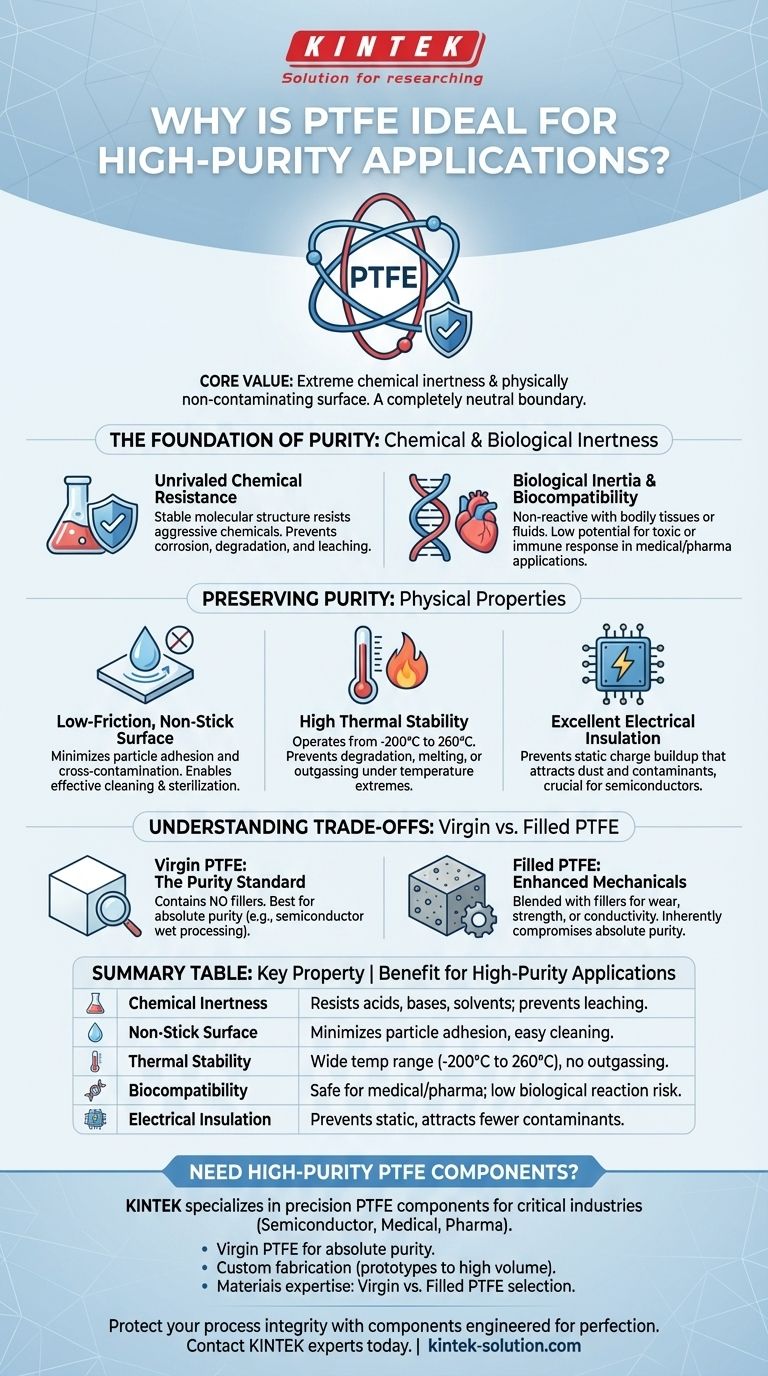

The Foundation of Purity: Chemical and Biological Inertness

The primary reason PTFE is specified for sensitive applications is its inability to chemically interact with its environment. This inertness is the bedrock of its performance in high-purity systems.

Unrivaled Chemical Resistance

The molecular structure of PTFE is exceptionally stable. This makes it resistant to virtually all industrial chemicals, including aggressive acids, bases, and solvents.

Unlike other materials that can corrode, degrade, or leach substances over time, PTFE maintains its integrity. This prevents the material from breaking down and introducing impurities into a fluid path or container.

Biological Inertia and Biocompatibility

In medical and pharmaceutical contexts, PTFE is considered highly biocompatible. This means it has a very low potential to cause a reaction when in contact with the body, tissues, or bodily fluids.

This "biological inertia" makes it a trusted material for medical implants, lab equipment, and pharmaceutical manufacturing, where preventing a toxic or immune response is critical.

Preserving Purity Through Physical Properties

Beyond its chemical makeup, PTFE's physical characteristics actively prevent contamination and ensure process stability. These properties are just as crucial as its chemical inertness.

A Low-Friction, Non-Stick Surface

PTFE is renowned for its extremely low coefficient of friction and non-stick, or non-adhesive, properties. In high-purity fluid handling, this means particles are far less likely to adhere to the walls of tubing or vessels.

This prevents cross-contamination between batches and makes cleaning and sterilization processes exceptionally effective, ensuring no residual matter is left behind.

High Thermal Stability

PTFE operates effectively across an exceptionally wide temperature range, from cryogenic conditions (-200°C) up to 260°C.

This stability is vital for purity. Processes that involve heating, cooling, or steam sterilization (like autoclaving) will not cause the PTFE to degrade, melt, or release volatile compounds (outgassing), which would otherwise contaminate the system.

Excellent Electrical Insulation

PTFE is one of the best electrical insulators known. In applications like semiconductor manufacturing, this property prevents the buildup of static charges on surfaces that could otherwise attract and hold microscopic dust and contaminants.

Understanding the Trade-offs: Virgin vs. Filled PTFE

While pure PTFE is the benchmark for inertness, it is sometimes modified to enhance other properties. Understanding this distinction is critical for selecting the right material.

The Standard for Purity: Virgin PTFE

For applications demanding the absolute highest level of purity—such as semiconductor wet processing or trace analysis—virgin PTFE is the standard. This grade contains no fillers or additives, ensuring it is composed of nothing but pure Polytetrafluoroethylene.

When Additives Are Necessary

To improve mechanical properties like wear resistance, compressive strength, or thermal conductivity, PTFE can be blended with fillers like graphite, glass, or carbon. For example, PTFE graphite packing is used in high-pressure seals where enhanced thermal dissipation is required.

The Inherent Compromise

Adding fillers inherently compromises the absolute chemical purity of the material. While a filled PTFE is still highly resistant, the filler itself may not be as inert as the PTFE matrix. The choice always involves a trade-off between mechanical performance and ultimate purity.

Making the Right Choice for Your Goal

To select the correct material, you must align the grade of PTFE with the primary demand of your application.

- If your primary focus is absolute chemical purity (e.g., semiconductor fluid handling, analytical chemistry): Use virgin, unfilled PTFE to guarantee no leaching or material interaction.

- If your primary focus is biological compatibility (e.g., medical implants, pharmaceutical processing): Select a medical-grade PTFE that is certified for its biocompatibility and non-toxic properties.

- If your primary focus is mechanical performance under stress (e.g., dynamic seals, high-load bearings): Consider a filled PTFE, but carefully evaluate if the filler material is compatible with your process environment.

By understanding these core principles, you can confidently select PTFE as a material that actively protects the integrity of your most sensitive processes.

Summary Table:

| Key Property | Benefit for High-Purity Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents leaching and reaction. |

| Non-Stick Surface | Minimizes particle adhesion and cross-contamination; easy to clean and sterilize. |

| Thermal Stability | Withstands temperatures from -200°C to 260°C without degrading or outgassing. |

| Biocompatibility | Safe for medical and pharmaceutical use; low risk of causing biological reactions. |

| Electrical Insulation | Prevents static buildup that attracts contaminants, crucial for semiconductor processes. |

Need High-Purity PTFE Components for Your Critical Applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where contamination is not an option. Whether you're in semiconductor manufacturing, medical device production, or pharmaceutical processing, we provide:

- Virgin PTFE for absolute chemical purity.

- Custom fabrication from prototypes to high-volume orders.

- Materials expertise to help you choose between virgin or filled PTFE based on your mechanical and purity requirements.

Protect your process integrity with components engineered for perfection. Contact our experts today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications