At its core, Polytetrafluoroethylene (PTFE) is considered uniquely versatile because it simultaneously excels in three critical areas where most materials compromise. It offers extreme chemical inertness, a vast operational temperature range, and one of the lowest coefficients of friction of any solid. This rare combination allows it to solve multiple engineering challenges at once, making it indispensable across countless industries.

PTFE's value is not derived from a single dominant feature, but from its unique ability to deliver elite performance in chemical, thermal, and frictional resistance simultaneously. This allows it to function reliably in environments where other materials would quickly fail.

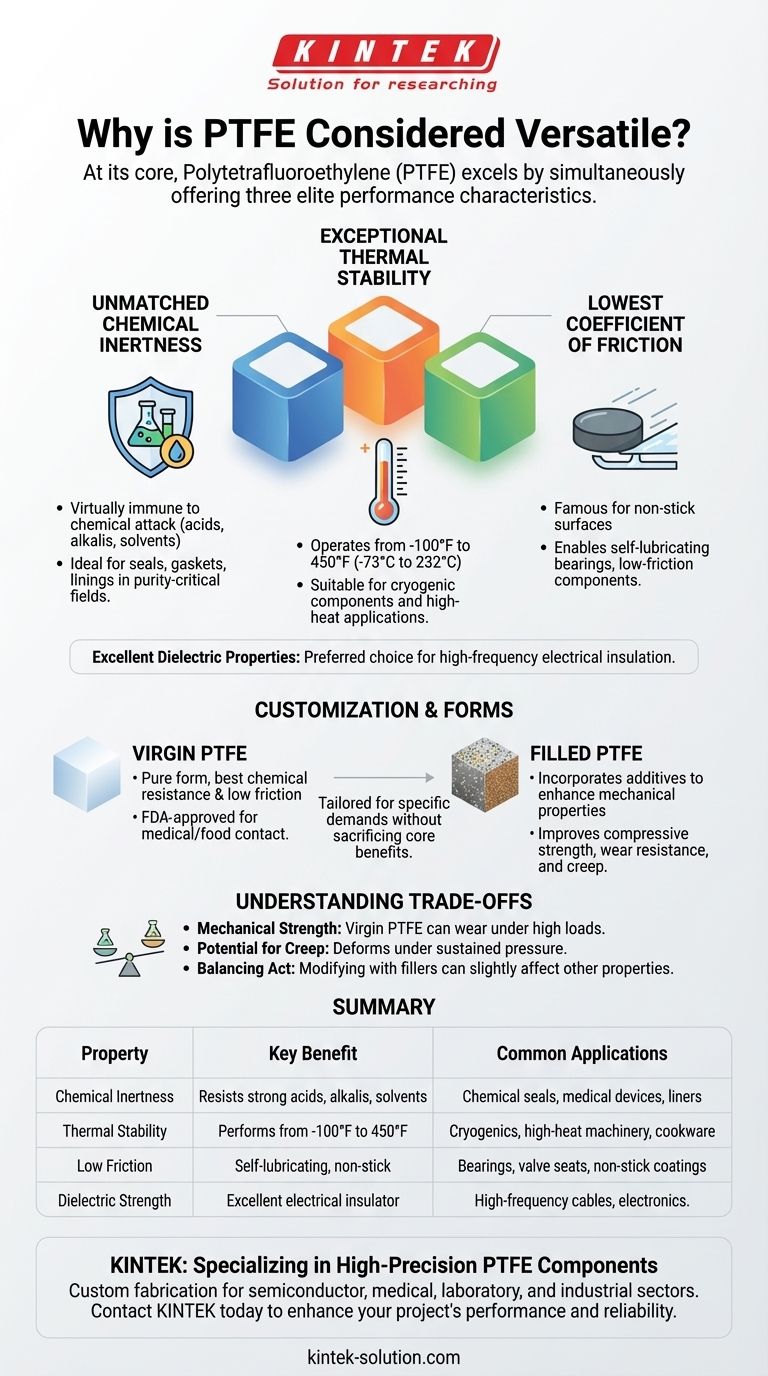

The Core Pillars of PTFE's Versatility

PTFE, often recognized by the brand name Teflon, owes its adaptability to a few fundamental properties that rarely coexist in a single material. Understanding these pillars is key to appreciating its widespread use.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It shows outstanding resistance to a wide range of substances, including strong acids, alkalis, and aggressive organic solvents.

This makes it an ideal material for seals, gaskets, and linings in chemical processing, pharmaceutical manufacturing, and medical equipment where material purity and non-reactivity are critical.

Exceptional Thermal Stability

The material maintains its structural integrity and performance characteristics across an extremely broad temperature spectrum, typically from -100°F to 450°F (-73°C to 232°C).

This allows PTFE to be used in applications ranging from cryogenic components in aerospace to high-heat applications in industrial machinery and non-stick cookware.

The Lowest Coefficient of Friction

PTFE has an exceptionally low coefficient of friction, meaning very few materials will stick to its surface. This "slipperiness" is what makes it famous as a non-stick coating.

In industrial settings, this property is crucial for creating self-lubricating bearings, low-friction valve seats, and other components where minimizing resistance and wear is essential for operational efficiency and longevity.

Excellent Dielectric Properties

Beyond its primary traits, PTFE is also an excellent electrical insulator. Its high dielectric strength makes it a preferred choice for insulating high-frequency cables and components in the electronics and aerospace industries.

Customization and Material Forms

PTFE is not a monolithic material. Its versatility is further enhanced by the ability to modify its properties with fillers and produce it in various forms to meet specific operational demands.

Virgin vs. Filled PTFE

Virgin PTFE is the pure, unmodified form. It offers the best chemical resistance, the lowest coefficient of friction, and is often FDA-approved for medical and food-contact applications.

Filled PTFE incorporates additives like glass, carbon, or bronze into the base material. These fillers are used to enhance specific mechanical properties that virgin PTFE may lack.

The Purpose of Fillers

Adding fillers can significantly improve characteristics such as compressive strength, wear resistance, and resistance to creep (the tendency to deform under constant load).

This allows engineers to specify a grade of PTFE that is perfectly tailored to a high-stress mechanical application without sacrificing its core benefits.

Diverse Manufacturing Options

PTFE can be manufactured into compressed sheets, rods, and tubes, making it highly machinable for custom parts. It can also be applied as a coating to other materials, further extending its use cases.

Understanding the Trade-offs

While incredibly versatile, PTFE is not the perfect solution for every problem. Its primary limitations are mechanical in nature, which is precisely why filled grades exist.

Mechanical Strength

Virgin PTFE is a relatively soft material. In applications with high mechanical loads or abrasive forces, it can be prone to wear and deformation.

Potential for Creep

Under sustained pressure, especially at elevated temperatures, pure PTFE can slowly deform or "creep." For structural applications requiring tight tolerances under load, a filled grade is almost always a better choice.

Balancing Properties and Cost

Modifying PTFE with fillers to improve one property, such as wear resistance, can sometimes slightly reduce another, like its absolute chemical inertness. Different forms and grades also come at different price points, requiring a careful balance of performance needs and budget.

Making the Right Choice for Your Application

Selecting the correct type of PTFE depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical purity and inertness: Virgin PTFE is the definitive choice for medical, pharmaceutical, and food-grade applications.

- If your primary focus is mechanical wear and strength: A filled PTFE, such as a glass- or carbon-filled variant, will provide the durability required for bearings and seals under high loads.

- If your primary focus is reducing friction in moving parts: Both virgin and filled PTFE offer excellent low-friction performance, with the choice depending on the specific load and wear requirements.

- If your primary focus is high-frequency electrical insulation: Virgin PTFE provides the best dielectric properties for sensitive electronics and coaxial cables.

Ultimately, understanding these core properties and available modifications allows you to leverage PTFE not just as a material, but as a strategic engineering solution.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists strong acids, alkalis, solvents | Chemical seals, medical devices, liners |

| Thermal Stability | Performs from -100°F to 450°F | Cryogenics, high-heat machinery, cookware |

| Low Friction | Self-lubricating, non-stick | Bearings, valve seats, non-stick coatings |

| Dielectric Strength | Excellent electrical insulator | High-frequency cables, electronics |

Need a PTFE component tailored to your specific chemical, thermal, or mechanical challenges?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the purity of virgin PTFE for medical applications or the enhanced strength of a filled grade for demanding industrial use, our custom fabrication services can deliver from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss